Prefabricated duplex block concrete construction mixing ratio and manufacturing technology thereof

A concrete and mix ratio technology, which is applied in the field of prefabricated double block concrete construction mix ratio, can solve the problems of insufficient concrete vibration, large temperature difference between inside and outside, and unreasonable layering, so as to delay the time of thermal insulation temperature rise and reduce thermal insulation The effect of temperature rise and prolonged stirring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the content of the invention, features and effects of the present invention, the following examples are hereby given:

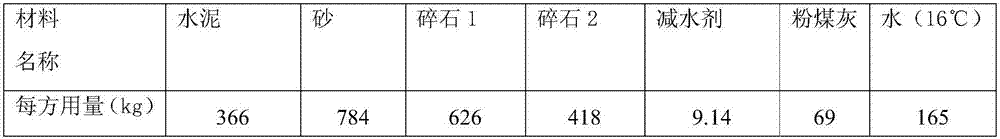

[0029] A construction mix ratio of prefabricated double-joint block concrete, which adopts the raw materials in the following proportions and is evenly mixed by a concrete mixer, with a bulk density of 2300-2500kg / m 3 ; The specific mix ratio is: cement: 350 ~ 370kg / m 3 ;Sand: 770~790kg / m 3 ;gravel 1 : 620~650kg / m 3 ;gravel 2 : 415~435kg / m 3 ;Polycarboxylate high-performance water reducer: 8.80~9.20kg / m 3 ; Fly ash: 60~80kg / m 3 ;Water: 160~170kg / m 3 .

[0030] The present invention can also adopt following technical measures:

[0031] The strength grade of the cement is P.042.5, and its specific surface area is 300-350㎡ / kg.

[0032] The sand is medium sand with a fineness modulus of 2.4-2.9 and a mud content of less than 3%.

[0033] The gravel 1 Grain gradation is 10-20mm, gravel 2 The particle gradation is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com