Draining and moisture exhaust device for direct-buried steam pipe

A steam pipe and water-repelling technology, which is applied in steam traps, mechanical equipment, etc., can solve the problems of reduced service life of insulation layer materials, influence of pipeline thermal efficiency and service life, and increase of pipeline heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

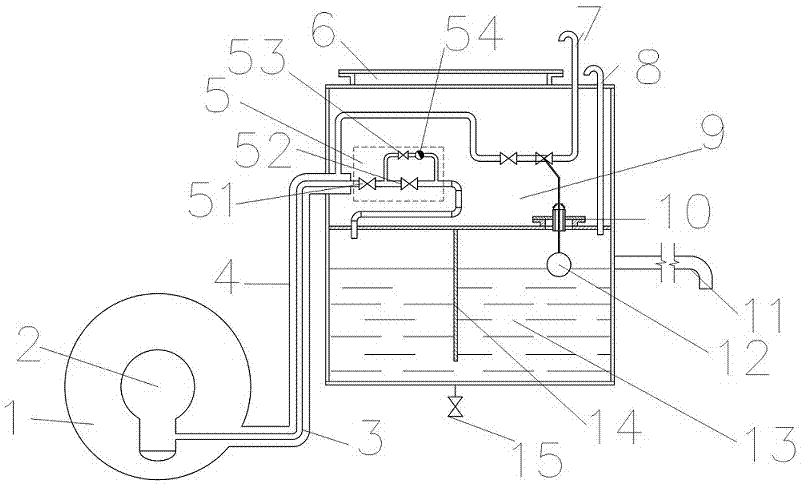

[0018] Below in conjunction with accompanying drawing, further explain the present invention.

[0019] Such as figure 1 As shown, the working pipe 2 is a directly buried steam working pipe, and the insulation layer is between the outer casing 1 and the working pipe 2 . Generally, there is high-temperature steam in the working tube 1, and the temperature can reach 100-250 degrees Celsius. The working tube 2 is connected with a water collector 21. The high-temperature steam in the working tube 2 will produce condensed water, and the temperature of the condensed water is generally 70-80 degrees Celsius. The cooling water tank 13 of the present invention is generally buried in the pit well, and the cooling water tank 13 is divided into an upper water tank 9 and a lower water tank by a dividing plate 16. 14 is not connected with the bottom of cooling water tank, like this, lower water tank will be divided into two parts that communicate. During work, the lower part of water tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com