Intelligent empty bottle detection robot bottle bottom positioning method

A positioning method and robot technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as inability to achieve high-speed and high-precision bottle bottom positioning, defects in the area of anti-skid lines, and no use of anti-skid lines, achieving high speed and execution speed. Fast, strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

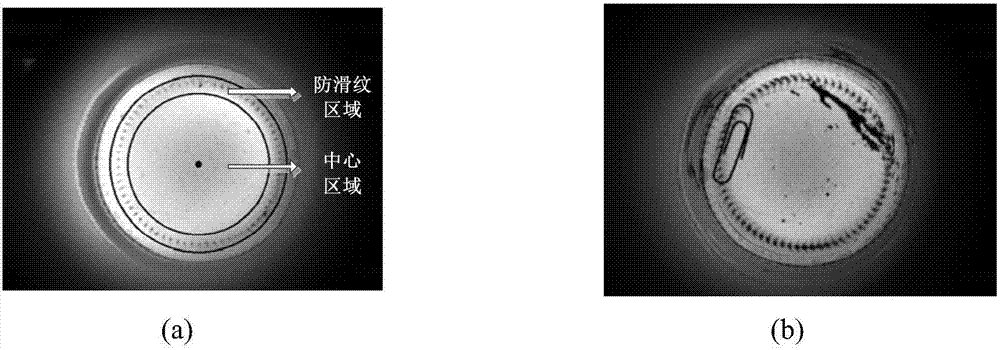

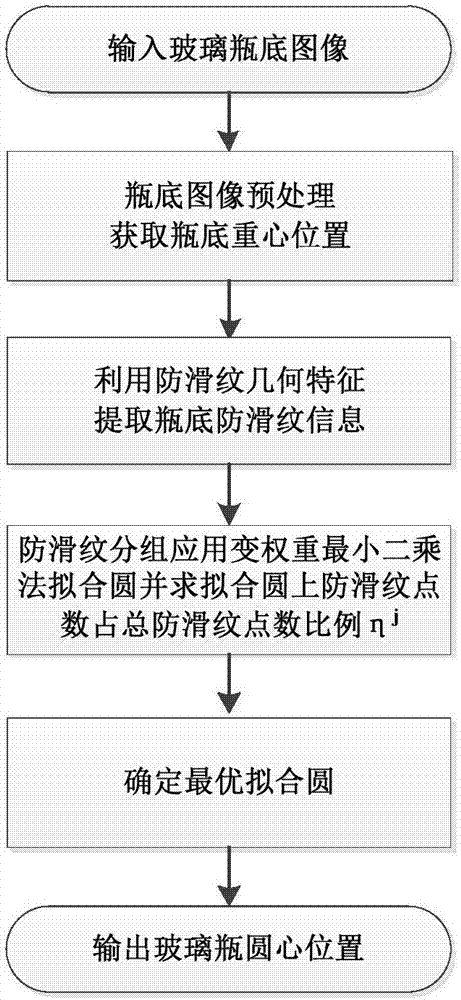

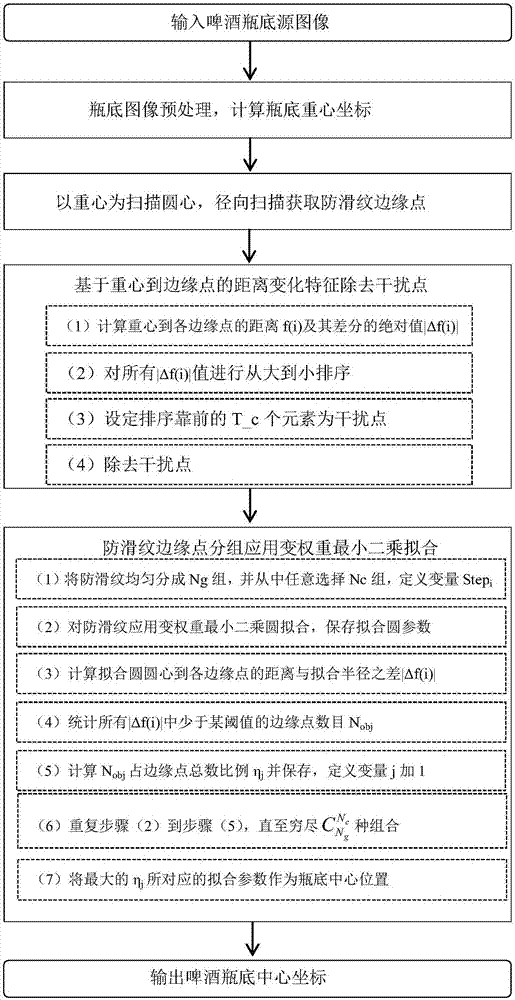

[0069] figure 1 (a) and (b) are the source images of the normal and intact bottle bottom and the bottom of the bottle with foreign body occlusion and continuous interference, respectively, where the anti-skid pattern and the inner area are marked with closed black solid lines, figure 2 and image 3 Respectively, the general block diagram of the glass bottle bottom positioning method flow process and the specific flow diagram of the present invention, the specific steps are as follows:

[0070] (1) The center of gravity method obtains the approximate position of the center of the bottom of the bottle.

[0071] First, the collected image of the bottom of the empty beer bottle is subjected to global threshold segmentation processing to obtain a binarized image of the bottom of the bottle, as shown in formula (1), where x and y represent the x and y coor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com