A milling cutter for thread milling with less interference

A technology for milling and thread milling, applied in thread cutting tools, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing tool life, affecting thread machining accuracy, uneven wear of cutting teeth, etc., to improve thread accuracy, The effect of prolonging the service life and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the contents of the present invention, and detailed implementation steps are given.

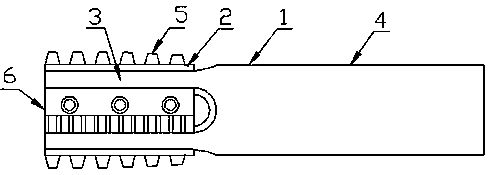

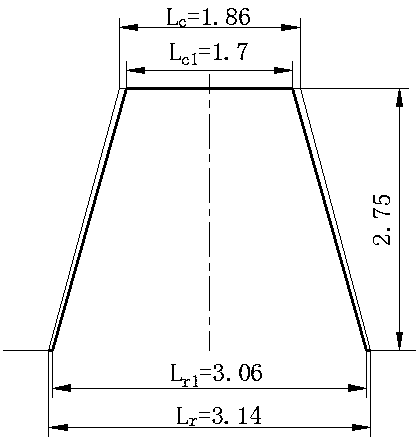

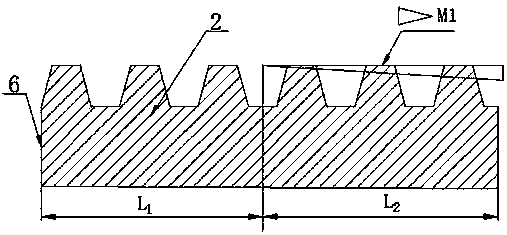

[0033] The implementation object of the present invention is a trapezoidal thread milling cutter, the major diameter D=24mm and minor diameter D of this trapezoidal thread milling cutter 1 =18.5mm, pitch P=5mm, which includes a tool body 1 that can rotate around the axis of rotation, and cutting blades 2 that are evenly distributed in the circumferential direction, and is characterized in that: the tooth shape of the cutting teeth on the cutting blade 2 is a The establishment of a special tooth profile that can reduce machining interference mainly includes the following steps:

[0034] 1) Establish thread theoretical tooth profile;

[0035] 2) Calculate the maximum overcut E during thread milling max ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com