Preparation method for producing thermoplastic polyvinyl chloride soft adhesive tape with two highlight surfaces and no flow mark

A polyvinyl chloride, plasticity technology, applied in the field of polyvinyl chloride soft tape, can solve the problem that it is not suitable for polyvinyl chloride soft tape, cannot produce embossed hot-melt tape, and the surface quality of polyvinyl chloride soft tape is not good And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

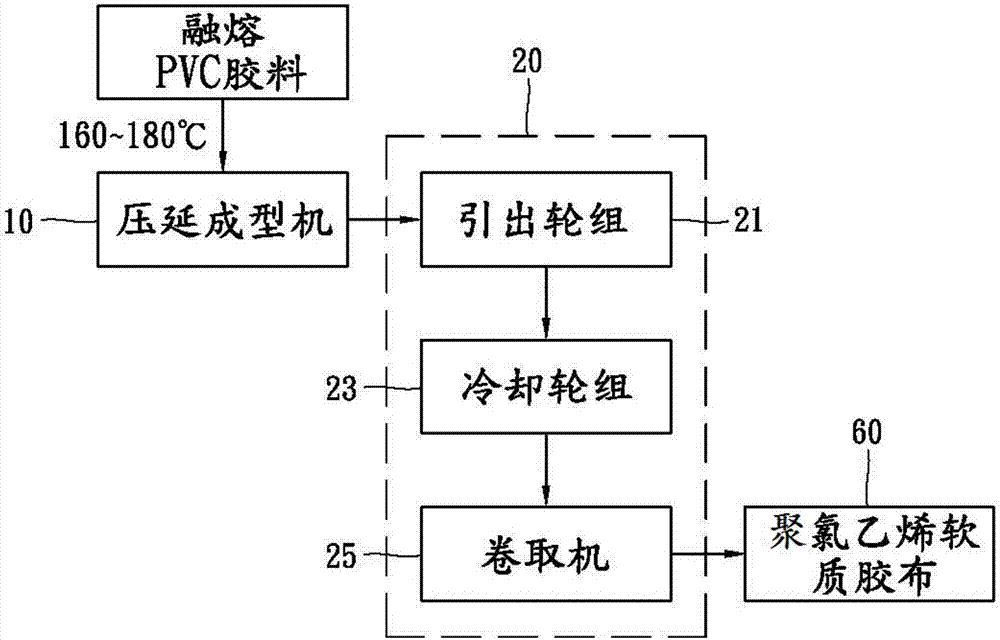

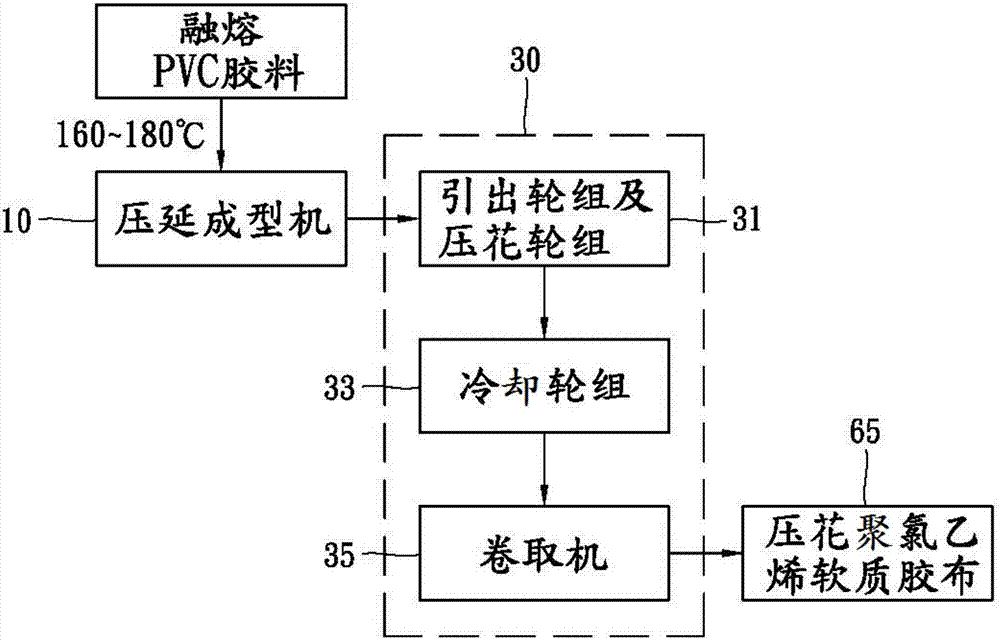

Method used

Image

Examples

Embodiment 1

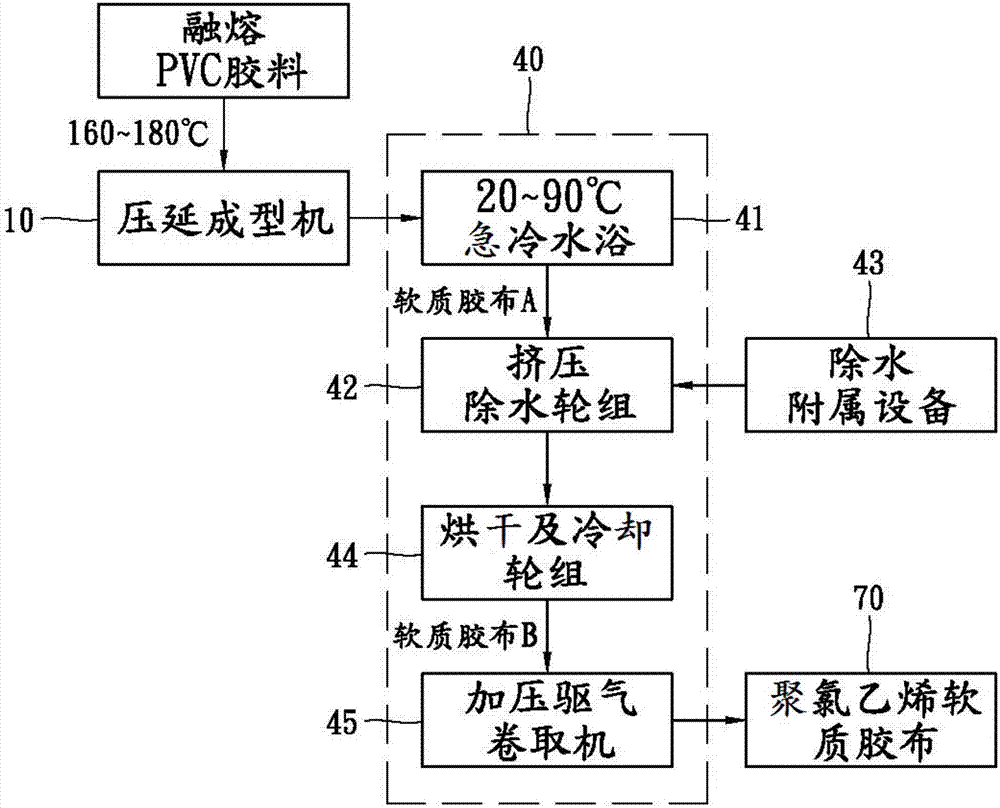

[0068] Production of double-sided high-gloss PVC soft adhesive tape with a thickness of 0.09mm and a softness of 24PHR (parts per hundred weight resin) without flow marks. According to the ratio of the raw materials specified below, use the mixer to mix the raw materials evenly into a mixture, then introduce a 10,000-horsepower machine for uniform mixing, and then fully gel the mixture through a roller machine to form a PVC melted rubber with a material temperature between 160 and 180 °C .

[0069]

[0070] Feed the melted PVC material into the calender molding machine to form a hot-melt PVC adhesive sheet with a thickness of 0.10mm. After forming, immediately introduce a 20-90°C quenching water bath to harden and set the shape instantly, so that the thickness of the hardened and shaped PVC adhesive sheet becomes 0.09mm, and The surface presents a flow mark-free state.

[0071] Guide the hardened and shaped PVC tape to pass through the extrusion water removal wheel group c...

Embodiment 2

[0074] Production of double-sided high-gloss PVC soft adhesive tape with a thickness of 0.65mm and a softness of 46PHR (parts per hundred weight resin) without flow marks. According to the ratio of the raw materials specified below, use the mixer to mix the raw materials evenly into a mixture, then introduce a 10,000-horsepower machine for uniform mixing, and then fully gel the mixture through a roller machine to form a PVC melted rubber with a material temperature between 160 and 180 °C .

[0075]

[0076] Except that the line speed of the pressurized air-driven coiler is changed to 50 ± 5m / min, the same as in Example 1, the PVC melted adhesive is made into a double-sided high-gloss non-flow mark and no dent Polyvinyl chloride (PVC) soft tape.

[0077] As shown in Table 1, the surface appearance of the prepared polyvinyl chloride (PVC) soft adhesive tape not only has no streamline dents, but also the gloss GV value of the upper surface and the bottom surface reaches 120, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Softness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com