A kind of preparation method of automobile door handle

A technology for door handles and automobiles, which can be used in household appliances, other household appliances, household components, etc., and can solve the problems of insufficient adhesion between plastic substrates and nickel-plated layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

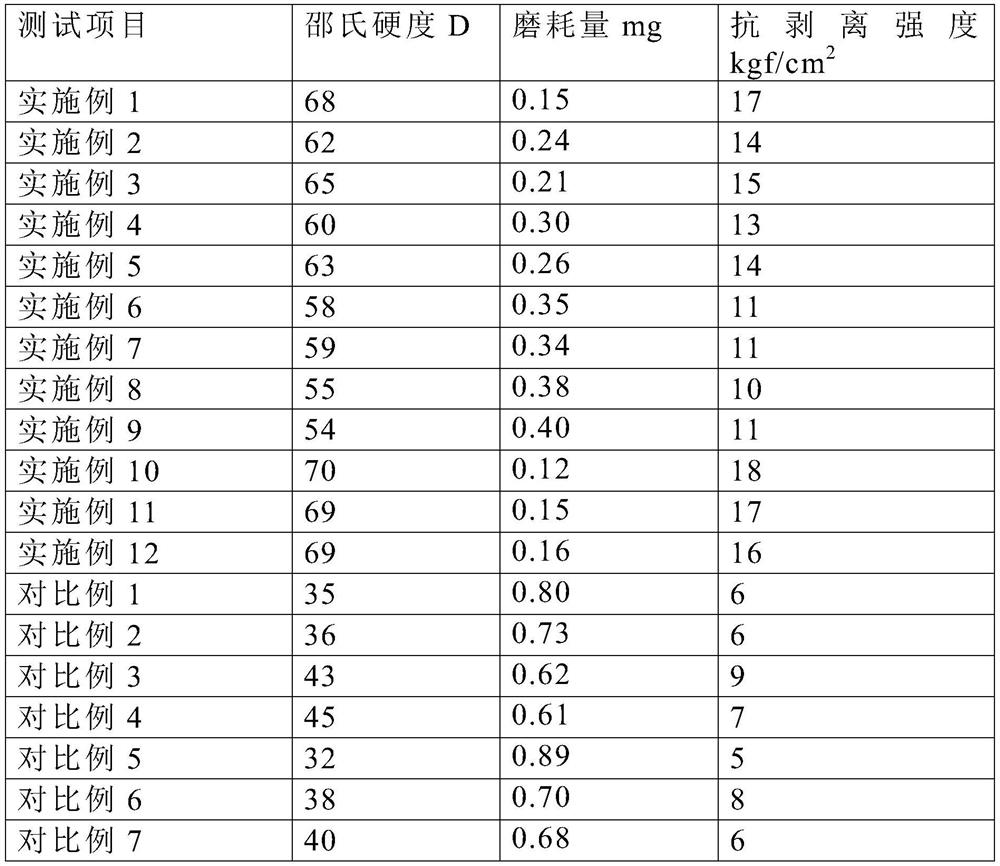

Examples

preparation example Construction

[0020] The preparation method of automobile door handle of the present invention comprises the following steps:

[0021] 1) Injection molding PC and ABS composite materials into the mold cavity to obtain the door handle blank;

[0022] In step 1), PC and ABS composite material are German Bayer T65 products, and the handle in the past all is to use the T45 product of Bayer, and the T65 product that the present invention uses, PC content is high, and the composite system of PC and ABS is more uniform. Dry the purchased T65 product in a dehumidification dryer to improve the stability of raw materials. Then put it into a screw injection molding machine, melt and blend, inject the melt into the mold cavity of the handle mold, go through the process of cooling and solidification, and demold to obtain the blank of the car door handle. The screw speed is 40-70rmp, and the barrel temperature of the injection molding machine is divided into four zones: inlet temperature 250-285°C, fron...

Embodiment 1

[0031] The preparation method of the automobile door handle of the present embodiment comprises the following steps:

[0032] 1) Dry the purchased German Bayer T65 product and put it into a screw injection molding machine, melt and blend it, inject the melt into the cavity of the handle mold, cool and solidify, and demould to obtain the door handle blank. The screw speed is 50rmp, and the barrel temperature of the injection molding machine is divided into four zones: the inlet temperature is 260°C, the front zone temperature is 265°C, the middle zone temperature is 270°C, and the rear zone temperature is 240°C. The injection molding pressure was 15,000 psi, the holding pressure was 65% of the injection molding pressure, the holding time was 3 minutes, and the injection mold temperature was 120°C.

[0033] 2) Soak the blank in 3% bisphenol A epoxy resin ethanol solution for 4 hours, then take it out and put it into the plasma reaction device, vacuumize it, and feed carbon dioxide...

Embodiment 2

[0036] The difference between embodiment 2 and embodiment 1 is that the ethanol solution concentration of bisphenol A epoxy resin in embodiment 2 is 0.3%, and the others are the same as embodiment 1, so they are not repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com