Efficient concrete performance enhancement additive and preparation method thereof

An additive and concrete technology, which is applied in the field of building materials, can solve the problems of limited waterproof ability of additives, restrictions on the application of concrete materials, poor self-tightness of concrete, etc., and achieve the effects of improving corrosion resistance, improving resistance to temperature changes, and enhancing bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

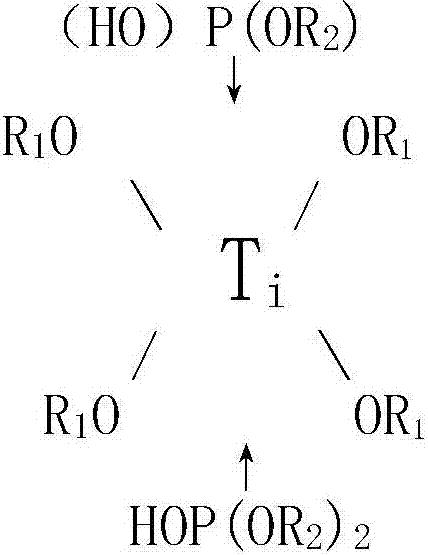

Method used

Image

Examples

Embodiment 1

[0023] First in parts by mass: titanate phosphate compounds (600 mesh, R 1 =C 8 , R 2 =C 12 ) 10 parts, zinc oxide (500 mesh) powder 6 parts, activated carbon (800 mesh) 5 parts, white carbon black powder (1200 mesh) 20 parts are sent into the mixer and fully mixed for 5 minutes to make powder. Then add 40 parts of polyester fibers (10 mm in length and 20 μm in diameter) to obtain product 1.

[0024] In order to test the performance of high-efficiency concrete performance-enhancing additives, the following methods are used for evaluation:

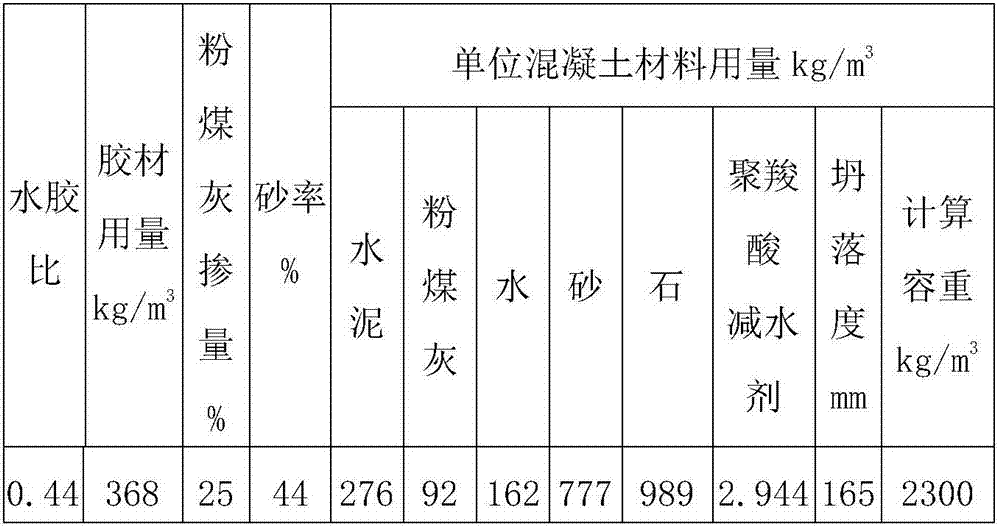

[0025] 1. Preparation of reference concrete

[0026] The benchmark concrete gradation is C35 concrete, see Table 1

[0027] Table I

[0028]

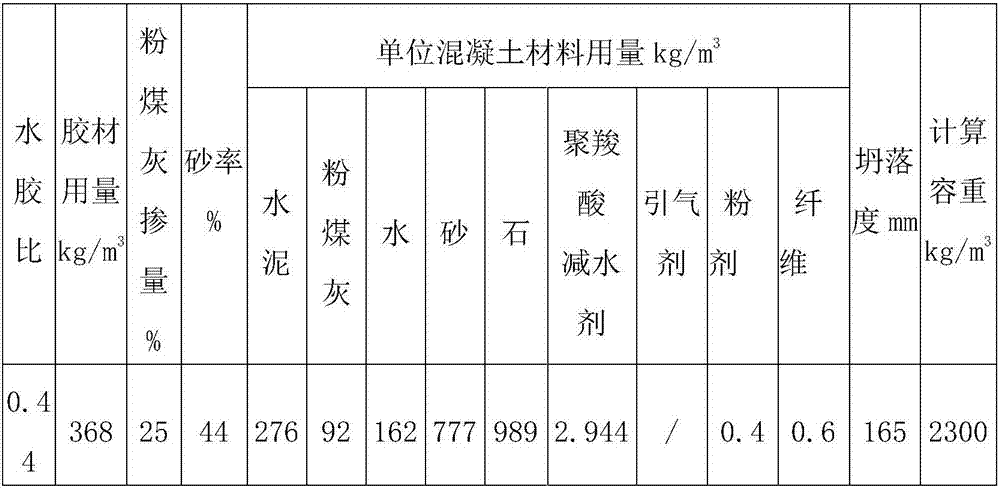

[0029] 2. Add high-efficiency concrete performance-enhancing additives to the benchmark concrete gradation C35, see

[0030] Table II

[0031]

Embodiment 2

[0033] First in parts by mass: titanate phosphate compounds (800 mesh, R 1 =C 10 , R 2 =C 14 ) 12 parts, zinc oxide (600 mesh) powder 6 parts, activated carbon (1000 mesh) 5 parts, white carbon black powder (2000 mesh) 20 parts are sent into the blender and fully mixed for 10 minutes to make powder. Then add 40 parts of polyester fibers (15 mm in length and 25 μm in diameter) to obtain product 2.

Embodiment 3

[0035] First in parts by mass: titanate phosphate compounds (1000 mesh, R 1 =C 10 , R 2 =C 16 ) 13 parts, zinc oxide (800 mesh) powder 6 parts, activated carbon (1200 mesh) 5 parts, white carbon black powder (3000 mesh) 20 parts are sent into the mixer and fully mixed for 12 minutes to make powder. Then add 40 parts of polyester fibers (15 mm in length and 20 μm in diameter) to obtain product 3.

[0036] 3. The preparation method is to add 1 kg of performance-enhancing additive products to 1 cubic meter of reference concrete (C35) to obtain concrete samples 1-3, and then test each concrete sample. The performance comparison is shown in the table below.

[0037] Table three

[0038] Pilot projects benchmark concrete Concrete 1 Concrete 2 Concrete 3 Improved impact and wear resistance 1% 8.7% 9% 9.5% Durability 100 times 300 times 312 times 325 times Splitting and axial tensile strength 2.2 2.6 2.7 2.78 Bending strength 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com