Concrete-encased double-limb steel pipe concrete dumbbell-shaped column structure and construction method thereof

A technology of steel pipe concrete columns and outsourcing concrete, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of poor corrosion resistance, influence of local stable structural bearing capacity, limited heavy load bearing, etc., and achieve enhanced fire resistance and corrosion resistance , improve the anti-wind and sand ability, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

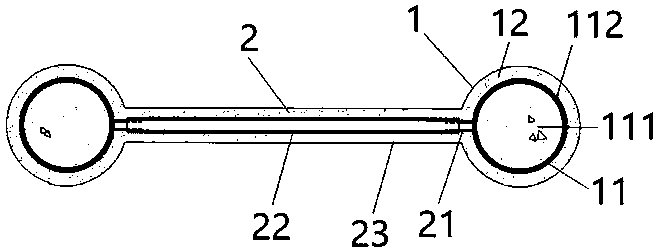

[0014] Such as figure 1 As shown, a steel tube concrete dumbbell-shaped column structure with two legs covered with concrete includes two column legs 1 and a reinforced concrete slab 2 connected between the two legs; Concrete columns all include concrete 111 in pipes and steel pipes 112; reinforced concrete slabs include node blocks 21, steel bars 22 and filled concrete layers 23, node blocks are connected to steel pipes and several node blocks are arranged along the axial spacing of steel pipes, and the two ends of steel bars They are respectively connected with the corresponding node blocks on the adjacent steel pipes, and the concrete in the pipes is commercial concrete, which is poured into the empty steel pipes.

[0015] In the embodiment of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com