A method and device for controlling a fuel metering system of an internal combustion engine

A technology of internal combustion engine and fuel, applied in the direction of electrical control, engine control, fuel injection control, etc., can solve the problem of not optimal fuel consumption, and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

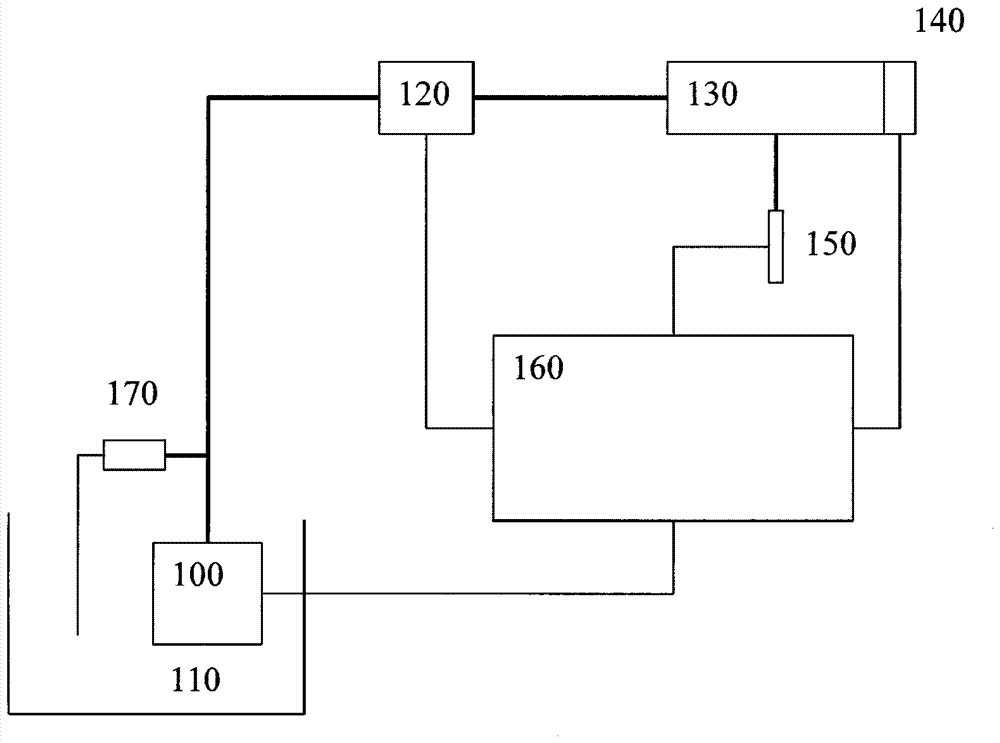

[0016] in figure 1 The basic elements of the fuel distribution system (Kraftstoffzumesssystem) are shown in. in figure 1 The Förderpumpe is marked with 100. The delivery pump delivers fuel from the storage tank 110 to the high-pressure pump 120. The high-pressure pump 120 builds up pressure in the high-pressure area. In particular, the high-pressure region includes a pressure accumulator (Druckspeicher), which is also referred to as a “rail” (Rail) 130. In addition, a pressure sensor 140 is arranged in the high pressure area. From the rail 130, fuel enters the combustion chamber of the internal combustion engine through the injector 150. The pressure build-up (the pressure build-up is performed by the opening and closing of the high-pressure pump 120, the ejector 150, and the power output of the delivery pump 100) is controlled by the control device 160. This control device 160 also analyzes the output signal of the pressure sensor 140.

[0017] The area between the delivery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com