LED filament lamp with gas dissipation function and machining process of LED filament lamp

A LED filament lamp and LED filament technology, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc., can solve the problem of unfavorable heat dissipation of LED filaments, high temperature of LED filaments, and short service life of products and other issues, to achieve the effect of increasing heat dissipation, good heat dissipation performance, and increasing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it should not be understood that the scope of the above-mentioned theme of the present invention is limited to the above-mentioned embodiments.

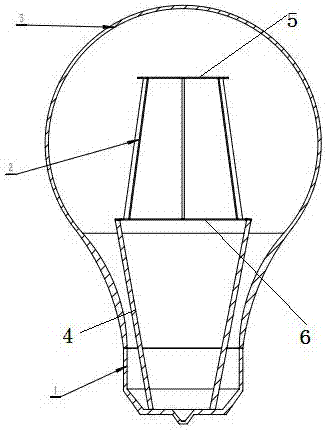

[0018] A gas-radiated LED filament lamp, comprising a lamp base 1, an LED filament 2 and a bulb 3, the lamp base 1 and the bulb 3 form a sealed space, and an upper bracket 5, an LED filament 2 and a lower bracket are arranged in the sealed space from top to bottom 6. The upper bracket 5 and the lower bracket 6 are used to fix the LED filament 2. The LED filament 2 is connected to the driving circuit through the wire 4, and the closed space is filled with a mixed gas of hydrogen, helium and air at 1.1 atmospheres, of which the volume of hydrogen occupies The proportion of helium is 6~10%, and the proportion of helium is 90~96%. A large number of experiments have proved that the mixed gas of this component has the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com