Flat wire type dynamic elasticity electric conducting system

A dynamic elastic, linear technology, applied in circuit layout, lighting device, lighting device components, etc., can solve problems such as unreliable performance, limited travel of barrel and tail cover, poor conductive contact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

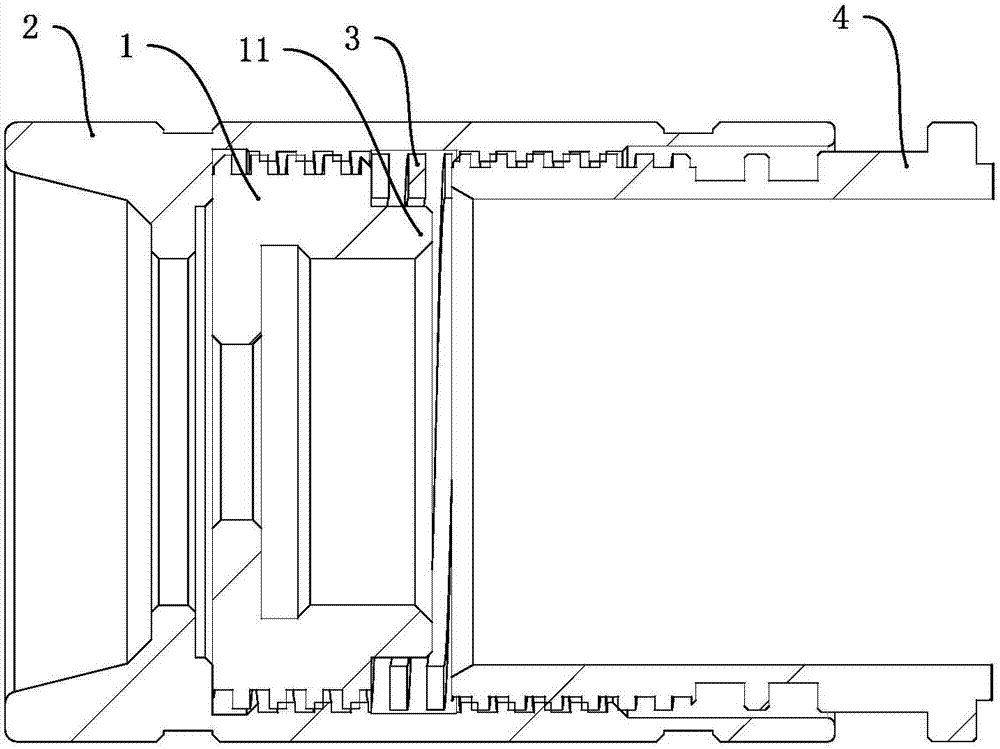

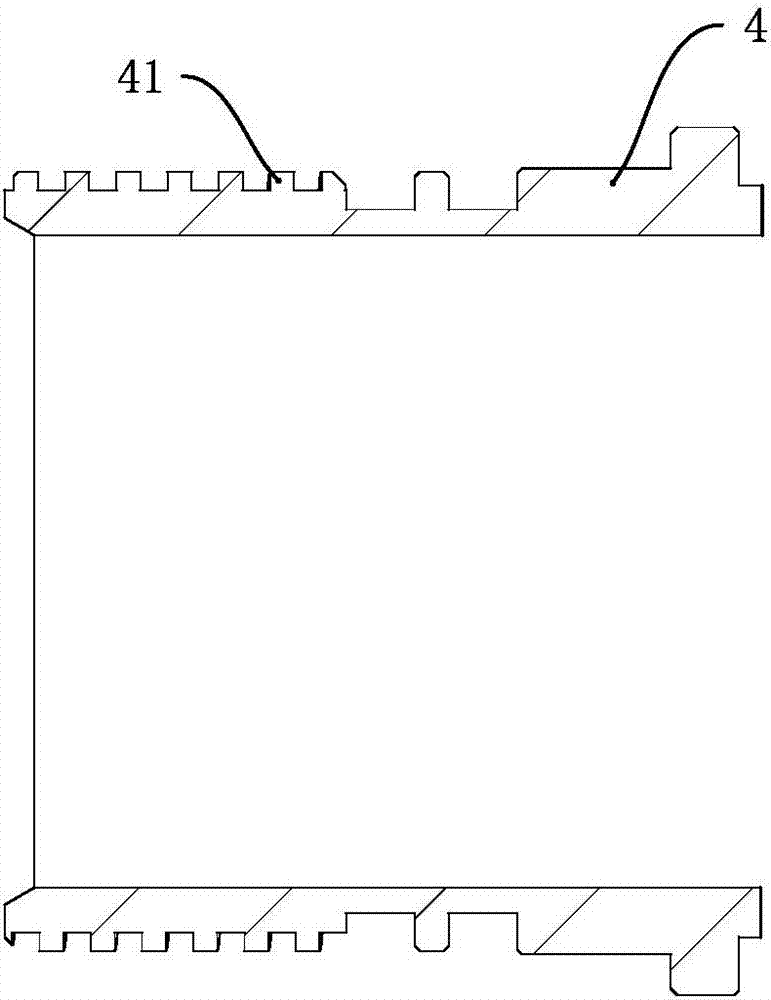

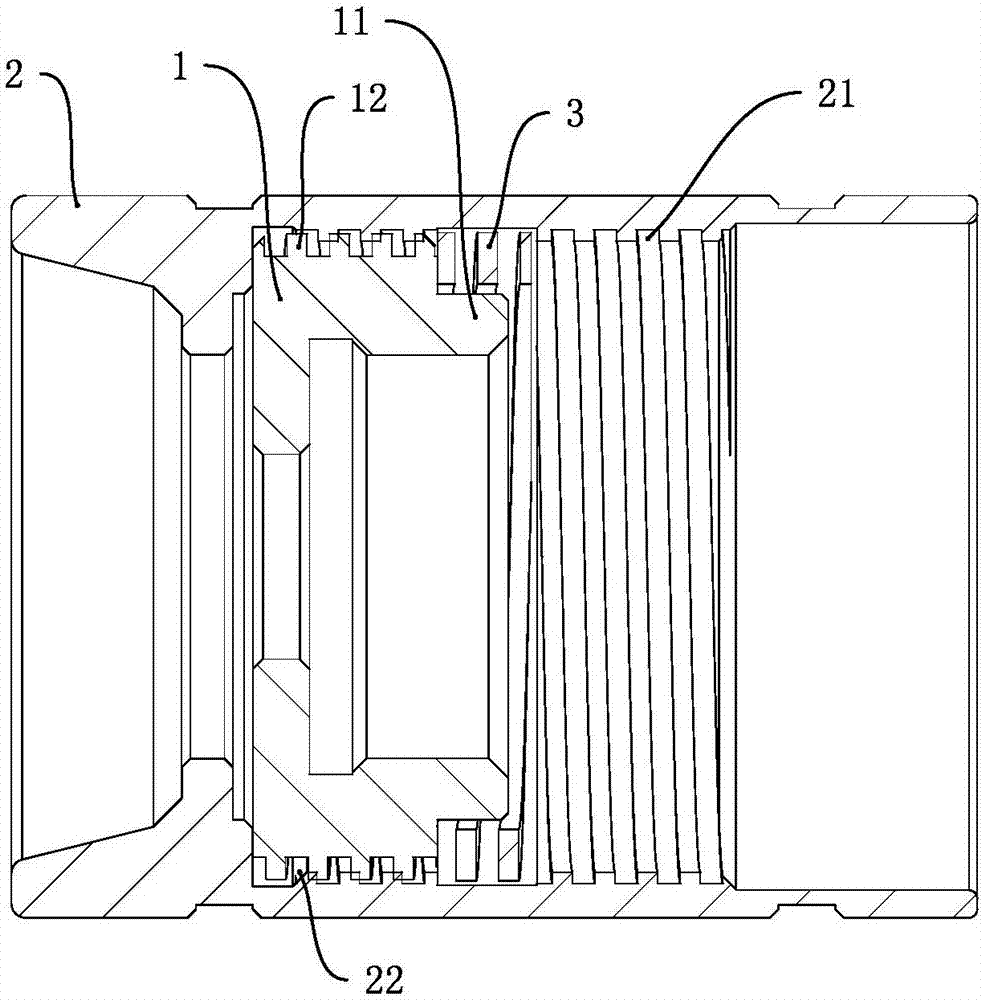

[0014] Such as Figure 1 to Figure 3 As shown, a flat wire type dynamic elastic conductive system includes a cylinder body 4, a tail cap 2 provided with an accommodating cavity, a switch frame 1 and a flat wire spring 3, the cylinder body 4 is provided with a first external thread 41, and the tail cap 2 There is a first internal thread 21 and the first internal thread 21 is close to the opening end of the tail cap 2, the switch frame 1 is set in the accommodating cavity and the switch frame 1 is in contact with the inner wall of the tail cap 2, the first external thread of the cylinder body 4 End 41 extends into the tail cap 2 and is threadedly connected with the tail cap 2. One end of the flat wire spring 3 abuts against the switch frame 1, and the other end abuts against the end surface of the cylinder body 4.

[0015] Such as Figure 1 to Figure 3 As shown, when the cylinder body 4 and the tail cap 2 are tightened, the end surface of the cylinder body 4 is pressed against ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com