Manufacturing mould for annular shearing test sample

A mold and ring shearing technology, which is applied in the field of making molds for ring shear test specimens, can solve problems such as damage, errors, and soil deformation, and achieve the effects of avoiding human errors, simple demoulding of samples, and avoiding disturbances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Utilize ring shear sample mold of the present invention to prepare the ring shear sample of remodeling soil, concrete steps are as follows:

[0028] (1) Prepare raw materials: completely dry the original soft clay, crush it through a 1mm sieve with a pulverizer, remove foreign matter in the soil, and weigh soil, cement, and water according to a certain ratio;

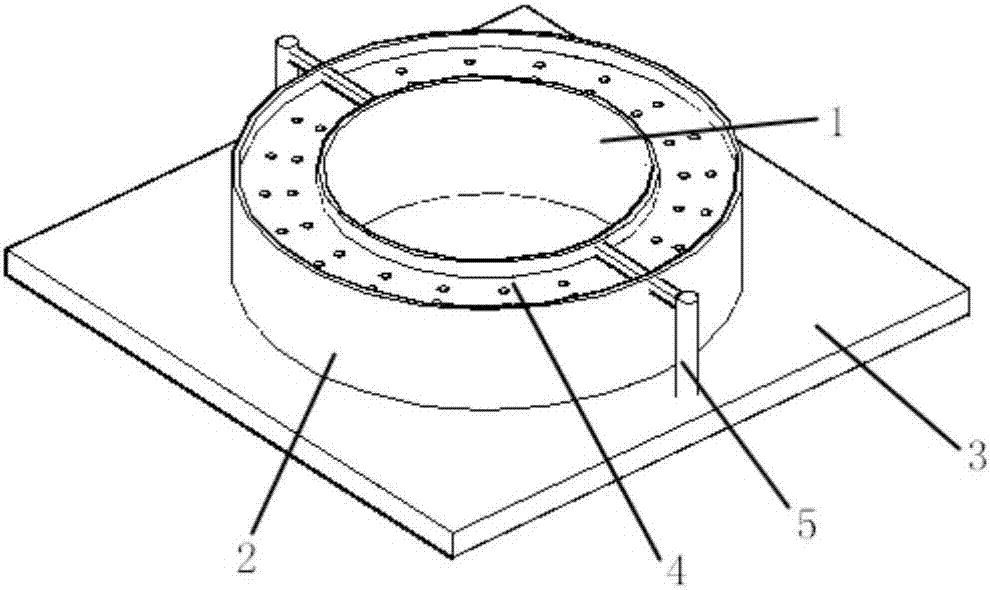

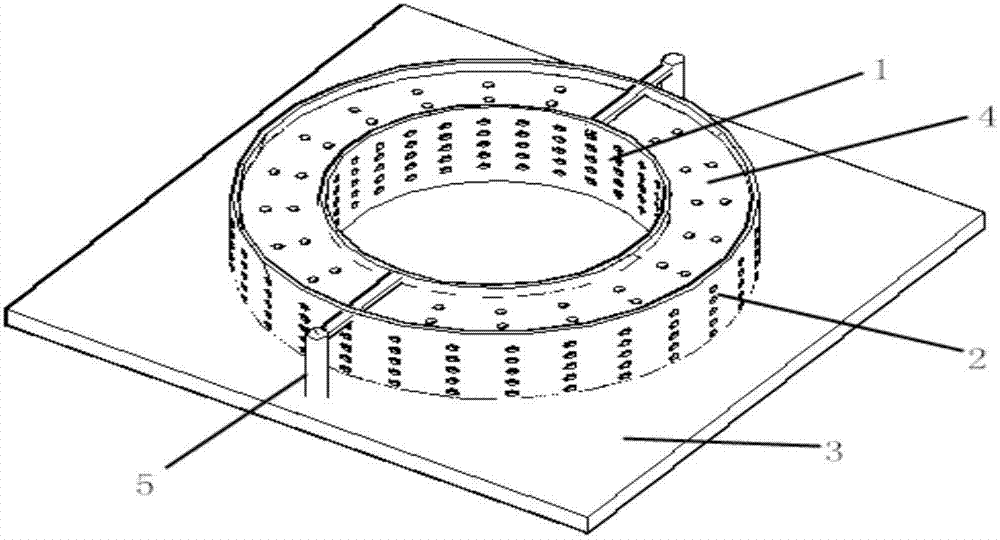

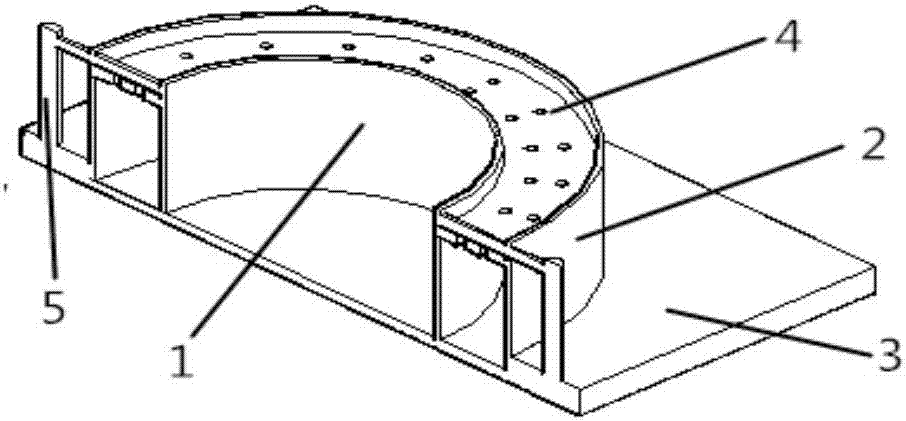

[0029] (2) Prepare the mold: this sample preparation utilizes the non-hole mold of the present invention, and the inner wall is all smeared with vaseline

[0030] (3) Sample preparation: Mix the weighed dry soil, cement and water evenly to form a slurry, pour it into the mold three times, and compact it with a compactor;

[0031] (4) Conservation and sample preparation: adjust the height of the annular cover 4, and seal and maintain the sample for 28 days; keep the temperature at 24° C. and the humidity at about 60 during the maintenance.

[0032] (5) Form removal and sampling: remove the ring cover 4, remove th...

Embodiment 2

[0034] Utilize ring shear sample mold of the present invention to prepare the ring shear sample of solidified light soil, concrete steps are as follows:

[0035] (1) Prepare raw materials: completely dry the undisturbed soft clay, crush it through a 1mm sieve with a pulverizer, take out sundries in the soil, and weigh dry soil, curing agent, foaming agent and water according to a certain proportion;

[0036] (2) Prepare the mould: this sample preparation utilizes the mold with holes of the present invention to wrap the outside of the inner ring 1, the inner side of the outer ring 2, and the top of the base 3 with an air-permeable and water-impermeable film;

[0037] (3) Sample preparation: Stir the weighed dry soil, curing agent, foaming agent and water evenly, pour them into the mold three times, and compact them with a compactor.

[0038] (4) Sample curing: put a breathable and impermeable film on the top of the sample, adjust the height of the ring cover 4, and seal the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com