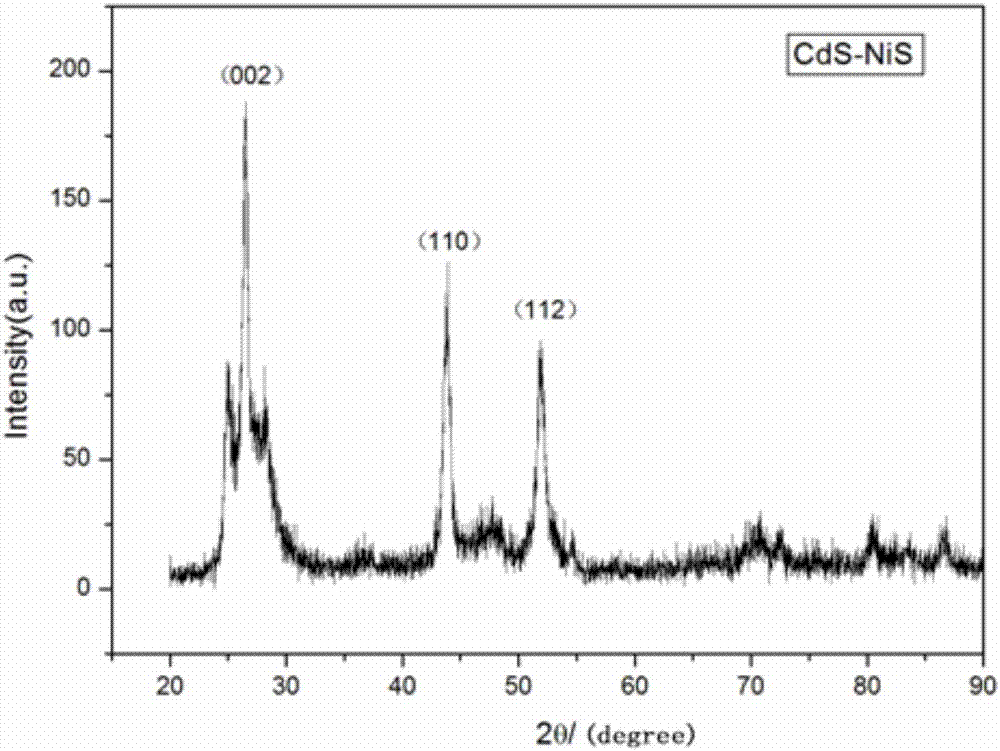

Preparation method of photocatalyst CdS-NiS nanocomposite material

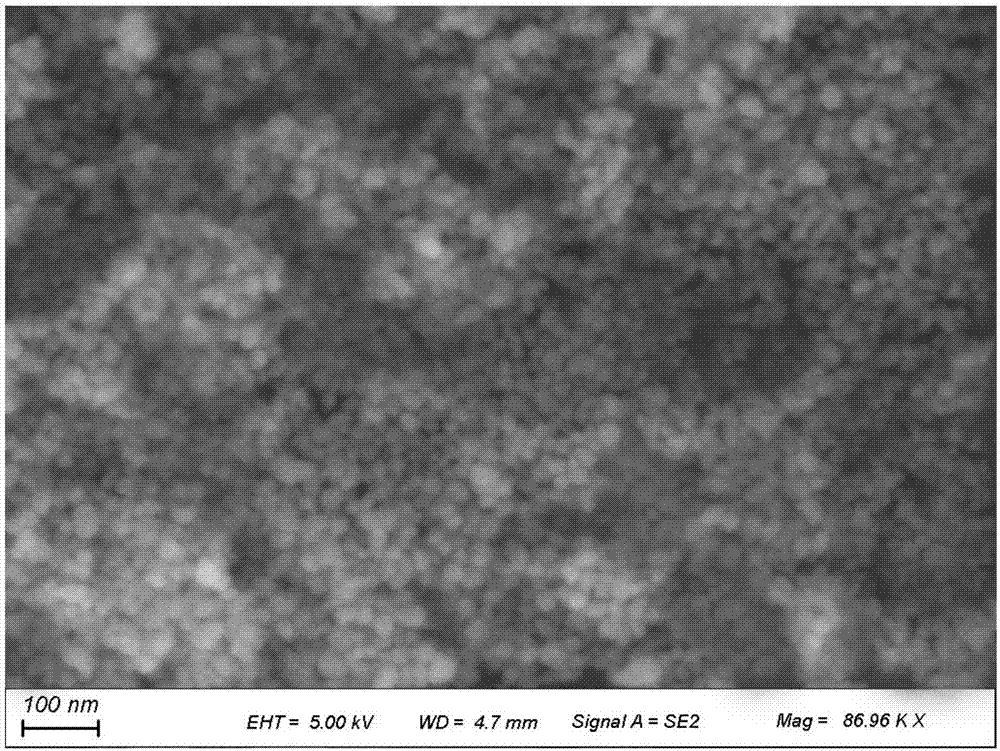

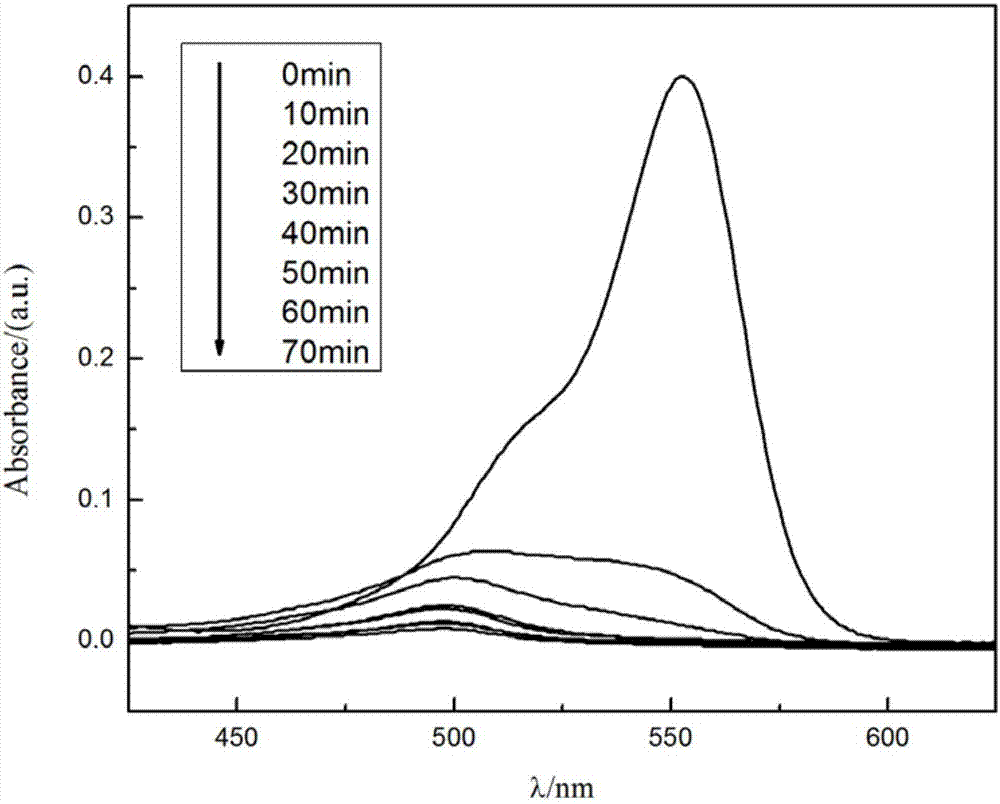

A nanocomposite material and photocatalyst technology, which is applied in the field of preparation of photocatalyst CdS-NiS nanocomposite materials, can solve the problems of high equipment requirements, expensive raw materials, time required for reaction, photocatalysts that cannot be mass-produced, etc. The effect of regular appearance and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] Example 1

[0027] A preparation method of a photocatalyst CdS-NiS nanocomposite material, comprising the following steps: adding 1.5 g of mercaptobenzothiazole cadmium into a 250 mL three-necked flask containing 80 mL of oleic acid, continuously stirring and heating to 100° C. After the solid is dissolved, continue to heat to 240°C for 5 minutes to complete the thermal decomposition of the complex. After cooling, the solid product was washed and centrifuged, the excess impurities were taken out, added to 50 mL of saturated sodium sulfide solution, heated in a constant temperature water bath at 65°C for 5 minutes, washed and centrifuged to remove excess sulfide ions, and then the solid product was dissolved in water and kept at a constant temperature of 65°C. Heating in a water bath, and slowly adding 50 mL of nickel chloride aqueous solution with a concentration ratio of 0.15 g: 50 mL dropwise, continuing the reaction for 5 minutes after the dropwise addition to stop h...

Example Embodiment

[0028] Example 2

[0029] The same conditions as in Example 1, the nickel chloride solution concentration ratio added dropwise was changed to 0.3 g: 50 mL to obtain a 20% Ni-doped composite metal sulfide CdS-NiS.

Example Embodiment

[0030] Example 3

[0031] Under the same conditions as in Example 1, the concentration ratio of the nickel chloride solution added dropwise was changed to 0.45 g:50 mL to obtain a 30% Ni-doped composite metal sulfide CdS-NiS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com