Concrete humidity control system and method

A humidity control system, concrete technology, applied in the direction of humidity control, control/regulation system, control device, etc., can solve the problems of long upgrade cycle, inaccurate control of concrete moisture content, complex structure of water adding control system, etc., to achieve moisture content control Accurate, convenient fault detection and maintenance, convenient upgrade and maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

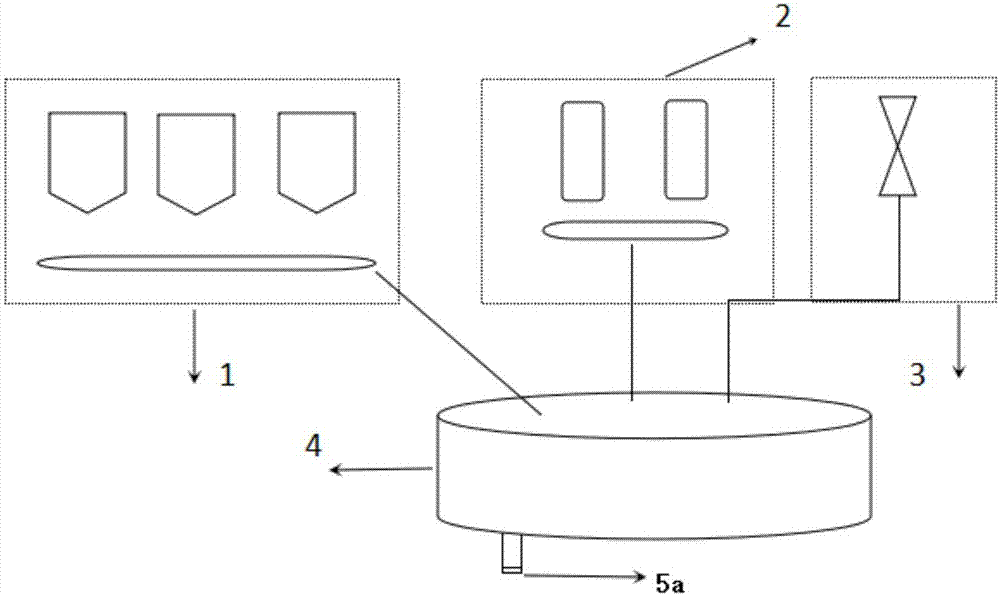

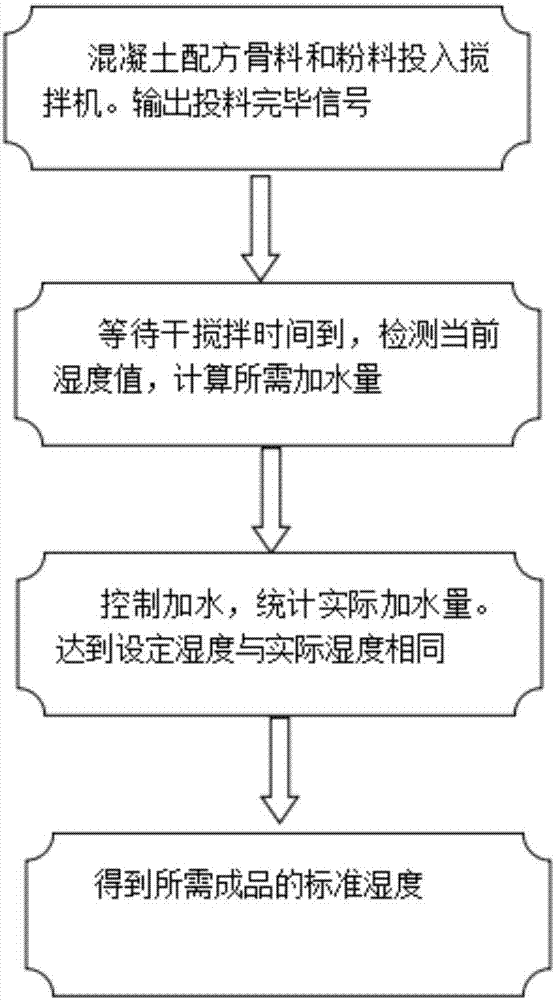

[0034] The invention provides a concrete humidity control system, which has an aggregate delivery unit 1 , a powder delivery unit 2 , a humidity detection control unit 3 and a mixing station 4 . The installation of the humidity detection control unit is required to be safe and reliable. For example, it should be installed on a moisture-proof and electric-shock-proof distribution box shell to prevent metal shavings and wire ends from falling into the vent hole of the controller, so as not to cause product failure and misoperation.

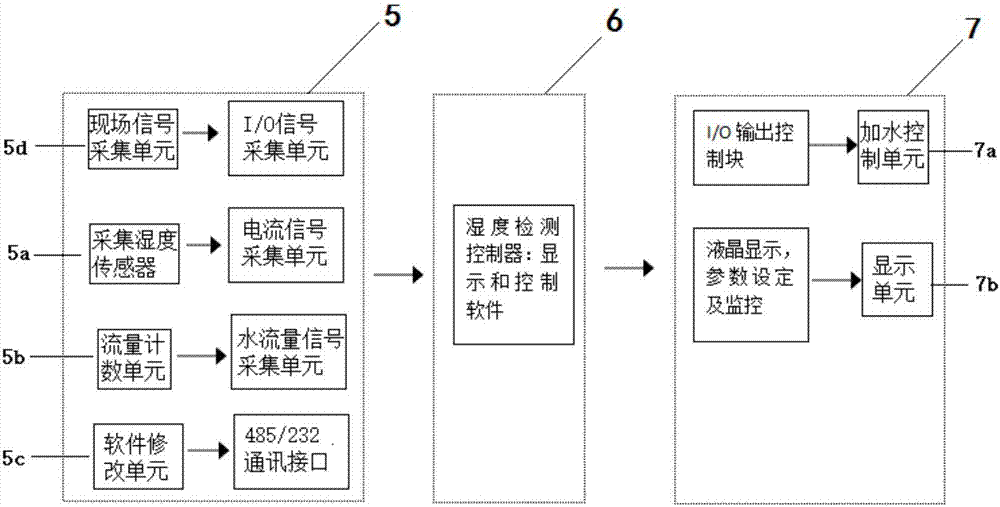

[0035] The humidity detection control unit 3 of the present invention includes a data acquisition unit 5, a data processing unit 6 and a control unit 7, wherein the data acquisition unit 5, the data processing unit 6 and the control unit 7 are connected through an interface module.

[0036] As an embodiment of the present invention, wherein the data acquisition unit 5 includes an acquisition humidity probe 5a, a flow counting unit 5b, a software modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com