Automatic coiling equipment for coiled materials

A complete set of equipment and coiled material technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of high labor intensity, low work efficiency, inapplicability, etc., and achieve the goal of reducing labor costs and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] In order to describe in detail the technical content, structural features, goals and effects achieved by a set of automatic coil loading equipment of the present invention, the following will be further explained in conjunction with the embodiments and accompanying drawings.

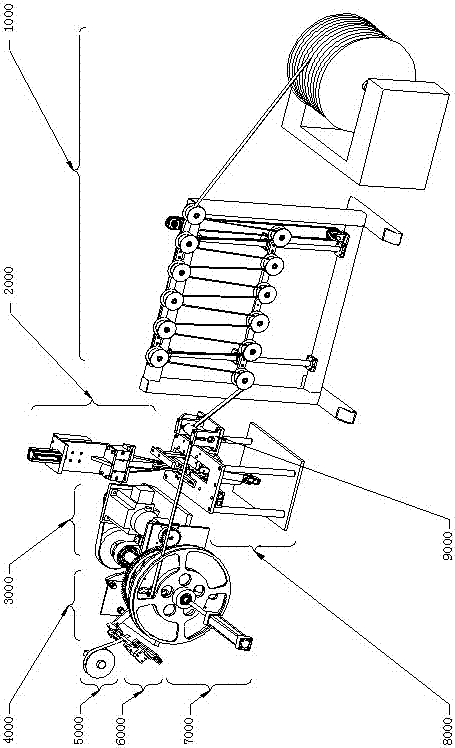

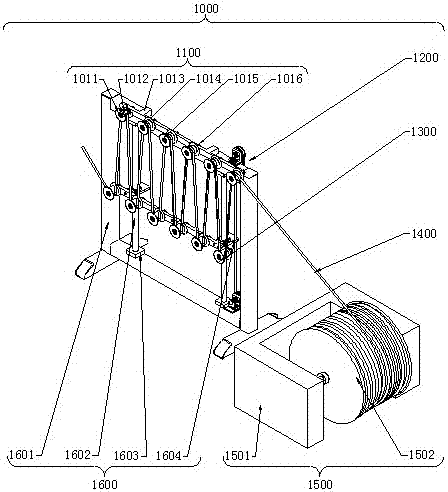

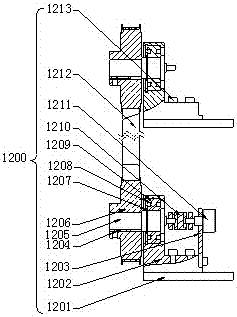

[0083] Such as Figure 1 to Figure 12 As shown, a group of embodiments of a set of automatic coil loading equipment of the present invention are disclosed, including: storage and unwinding device 1000, head traction device 2000, wire take-up device 3000, sandwich film feeding device 4000, film feeding device 5000, film cutting device 6000, top plate device 7000, tail cutting device 8000, meter counting device 9000; storage and unwinding device 1000 is located upstream of the coil travel direction, and continuously conveys coil 1400 to the head through the meter counting device 9000 for traction Device 2000; the head traction device 2000 is fixed above the tail cutting device 8000, and is pushed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com