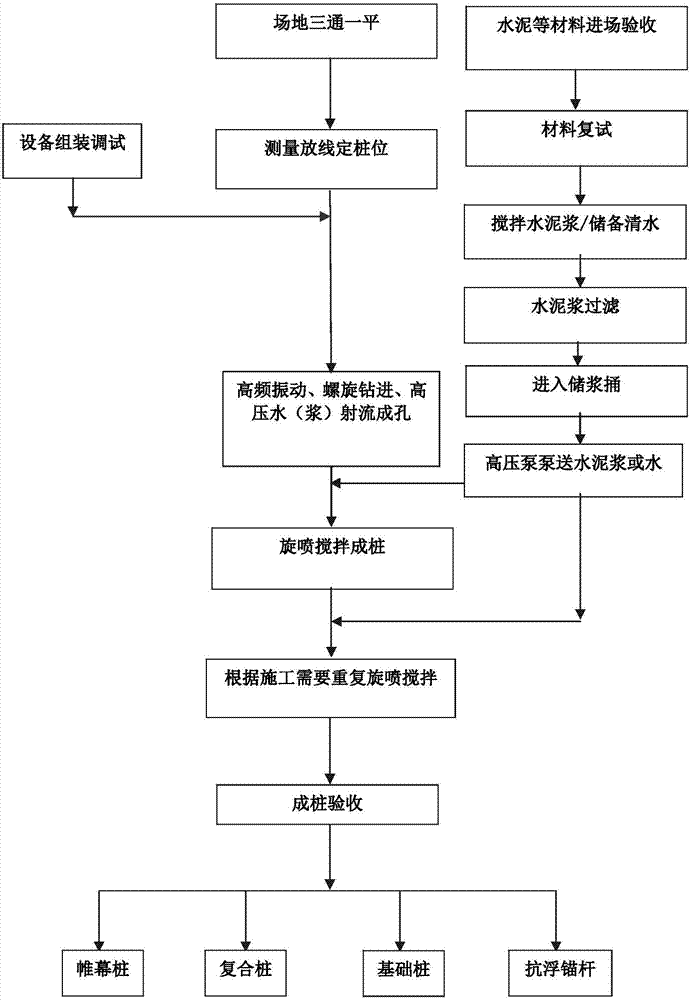

Down hole impacting rotary jetting mixing pile construction technology and device

A technology of construction equipment and construction technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of poor pile forming effect and poor drilling performance, and achieve the reduction of material consumption, cement consumption and simple frame structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

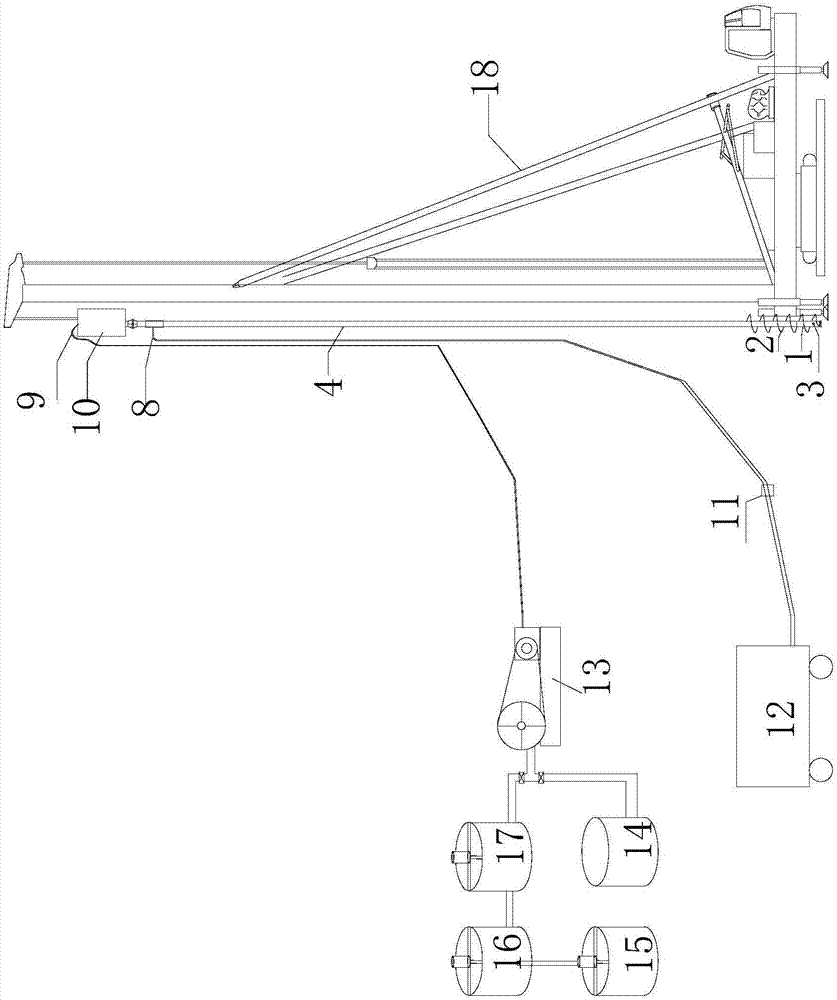

[0074] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

[0075] Such as image 3 As shown, the down-the-hole impact rotary jet mixing pile construction equipment of the present invention includes:

[0077] The down-the-hole impactor 1 is arranged at the bottom end of the drill rod 4;

[0078] The stirring device 2 is connected to the outside of the down-the-hole impactor 1; the stirring device and the down-the-hole impactor work synchronously;

[0079] Nozzle 3 is arranged on the side of the drill rod;

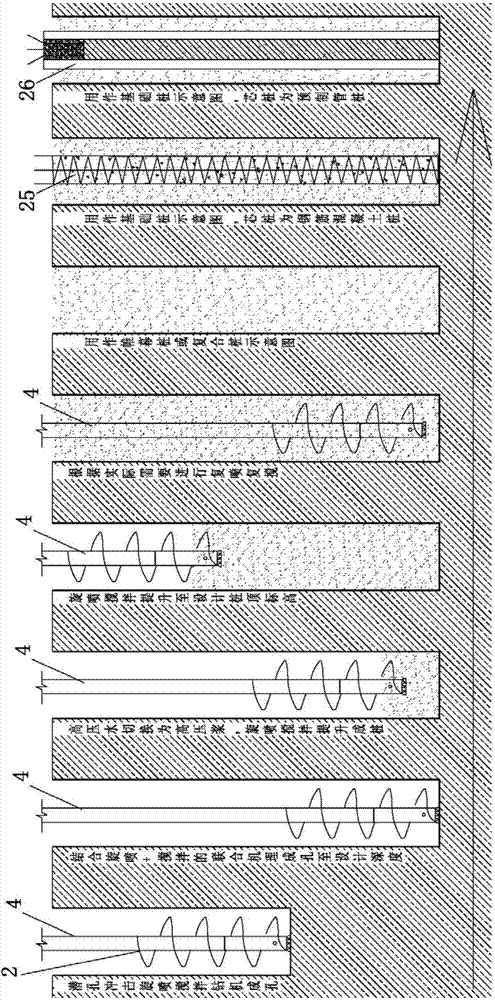

[0080] Such as Figure 4 As shown, the drill pipe 4 is provided with a through channel inside, respectively connected to the high-pressure slurry pipeline 5 and the high-pressure air passage 7 of the drill bit or the DTH impactor 1; the high-pressure slurry pipeline 5 is separated from the high-pressure air pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com