Semi-automatic construction method and device for inverted erection of steel structure building

A construction method and semi-automatic technology, which can be used in hoisting devices, processing of building materials, construction, etc., can solve the problems of difficult vertical assembly of super multi-layers, reduced construction safety, and prolonged construction period, and can eliminate large-scale hoisting. The use of machine and feeding machinery, shortening the construction period, and the effect of reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

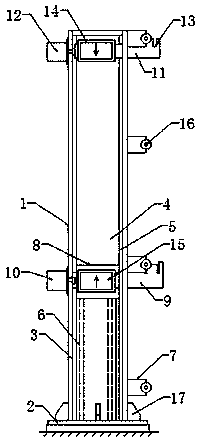

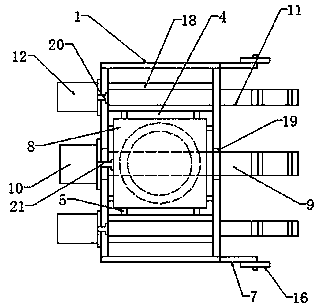

[0041] A semi-automatic construction method for flip-chip lifting of a steel structure building: comprising the following steps: pre-construction preparations - assembling flip-chip lifting frame mouldings - building body assembly - building body lifting - removal of on-site equipment and tooling;

[0042] 1. Preparatory work before construction:

[0043] 1) Complete the basic acceptance, processing, setting out, measurement, installation of construction equipment and tools;

[0044] 2) Determine the center point of the building;

[0045] 3) Complete three links and one leveling at the construction site;

[0046] 4) Complete the unpacking and technical acceptance of building parts, structural parts and standard parts;

[0047] 2. Assemble the flip-chip lifting frame touch:

[0048] The flip-mounted lifting frame includes a lifting device, multiple main column positioning devices and multiple independent foundations. The lifting device includes multiple lifting mechanisms. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com