Polymeric plasticizer compositions

A technology of composition and plasticizer, which is applied in the field of plasticized polymer composition and manufacture of the polymer plasticizer composition, can solve the problems that plasticizer is not easy to leach or evaporate, and is not suitable for health or environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0187] Example 1: General Procedure for Preparation of Polymeric Plasticizer Compositions

[0188] Polymeric plasticizer compositions were made using the general procedure described below.

[0189] Procedure when the source of aromatic acid is an aromatic diacid or ester or anhydride

[0190] Aromatic acid source, dihydric alcohol and C 4 -C 36 The monocarboxylic acid or its ester or anhydride was charged into a 4 neck round bottom flask reactor which was then placed in a heating mantle connected to a temperature controller. Connect the nitrogen inlet, thermocouple, and mechanical stirrer to the reactor. The reaction was carried out at 189-250°C under a nitrogen purge. When the appropriate acidity was reached by sampling and measuring the acid ester, the reaction was terminated and property studies were performed.

[0191] Procedure: Aromatic polyester or polycarbonate as aromatic acid source

[0192]A solid polymeric thermoplastic polyester such as PET is used as ...

Embodiment 2

[0219] Example 2: Plasticized polyvinyl chloride polymer composition

[0220] Plasticized polymer compositions are made using the polymeric plasticizer compositions of the present invention and the desired polymers using standard manufacturing techniques.

[0221] The plasticized polymers can be used, for example, as rubber substitutes and have applications in fields including cable insulation, flooring, coatings, pipes, intumescent products and artificial leather.

[0222] The formulations below are examples of plasticized polymer compositions that can be used for wire and cable coatings.

[0223] Plasticized polymer formulations for wire and cable applications

[0224] Polyvinyl chloride (PVC) resin: 100PHR

[0225] Polymeric plasticizer of the present invention: 35PHR

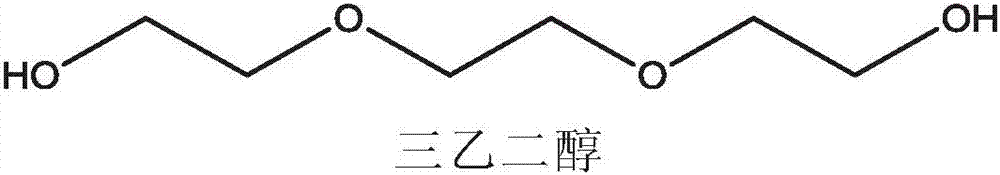

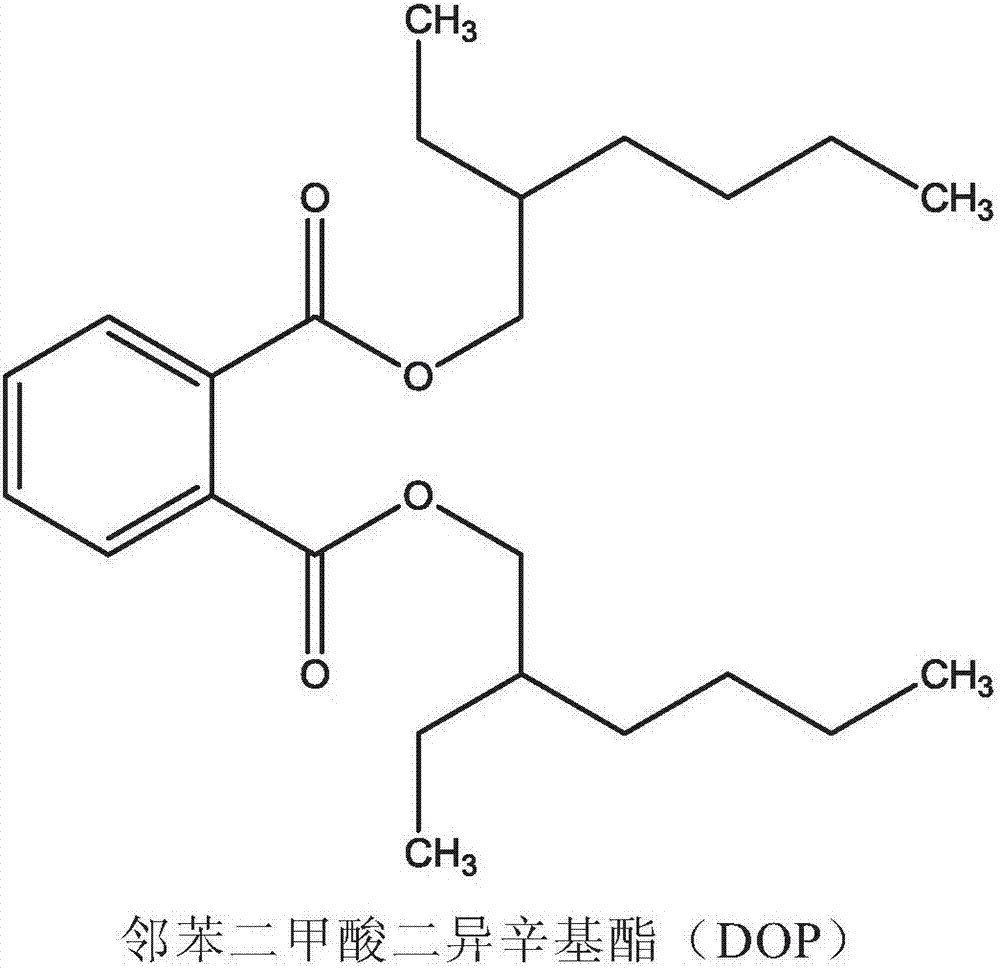

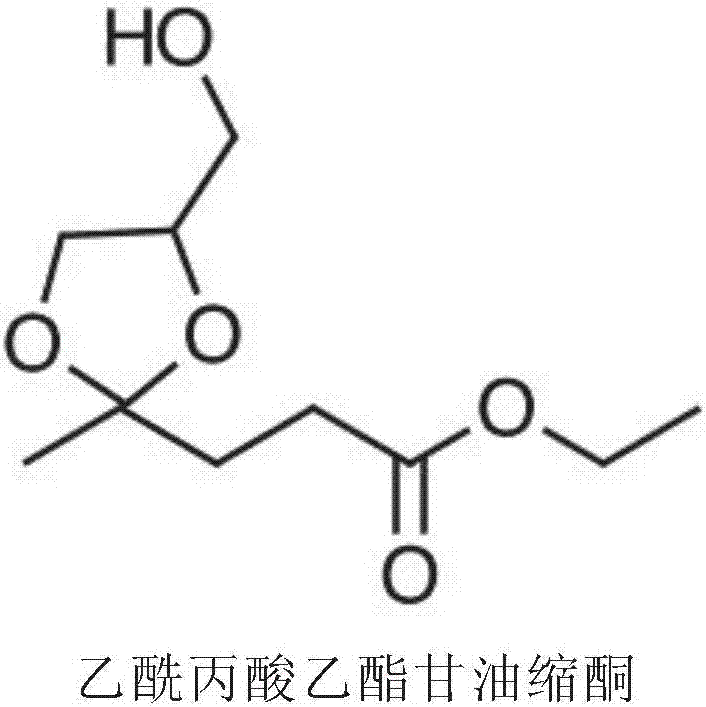

[0226] Additional low molecular weight plasticizer: 30PHR

[0227] Ca / Zn: 4.5PHR

[0228] Stearic acid: 0.2PHR

[0229] Calcined clay: 12PHR

[0231] In the above fo...

Embodiment 3

[0245] Example 3: Plasticized polyethylene terephthalate (PET) composition

[0246] 100 grams each of the PET pellets and the polymeric plasticizer composition 6 described in Example 1 were charged into a 500 mL 4 necked round bottom flask. The mixture was placed under a nitrogen atmosphere and heated at a temperature of 220°C with slow stirring until the particles were completely dissolved. The temperature of the reaction mixture was cooled to 200°C and poured into a Teflon pan to form an opaque tan material.

[0247]

[0248]

[0249] incorporated by reference

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com