Dimensional enhancement of artificial leather polyurethane composite material

A composite material, polyurethane layer technology, applied in the direction of textiles and papermaking, synthetic resin layered products, other household appliances, etc., can solve the problems of PU surface layer cutting, not enough to achieve embossing goals, and unable to properly protect composite materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

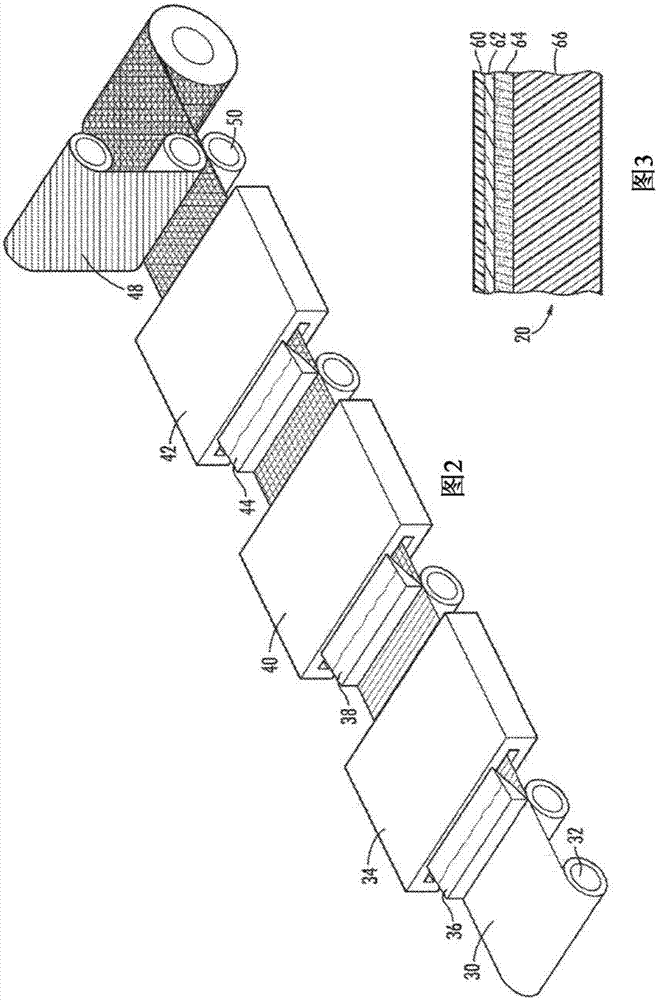

[0035] Certain preferred embodiments and examples are disclosed herein. However, the inventive subject matter extends beyond the examples of the specifically disclosed embodiments to other alternative embodiments and / or uses as well as modifications and equivalents of the inventive subject matter. Therefore, the scope of the appended claims is not to be limited by any particular embodiments described herein. For example, in any method or process disclosed herein, the acts or operations of the method or process may be performed in any suitable order and are not necessarily limited to any particular disclosed order. Various operations may be described as multiple discrete operations in a manner or order that is helpful in understanding certain embodiments; however, the order of description should not be construed as to imply that these operations are order dependent. Additionally, the structures, systems and / or devices described herein may be implemented as an integrated compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap