Novel multi-purpose dough pressing device

A multi-purpose and new technology, applied in the direction of dough extruder, dough forming and cutting equipment, etc., can solve the problems of material waste, inability to shape, inability to cut by itself, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

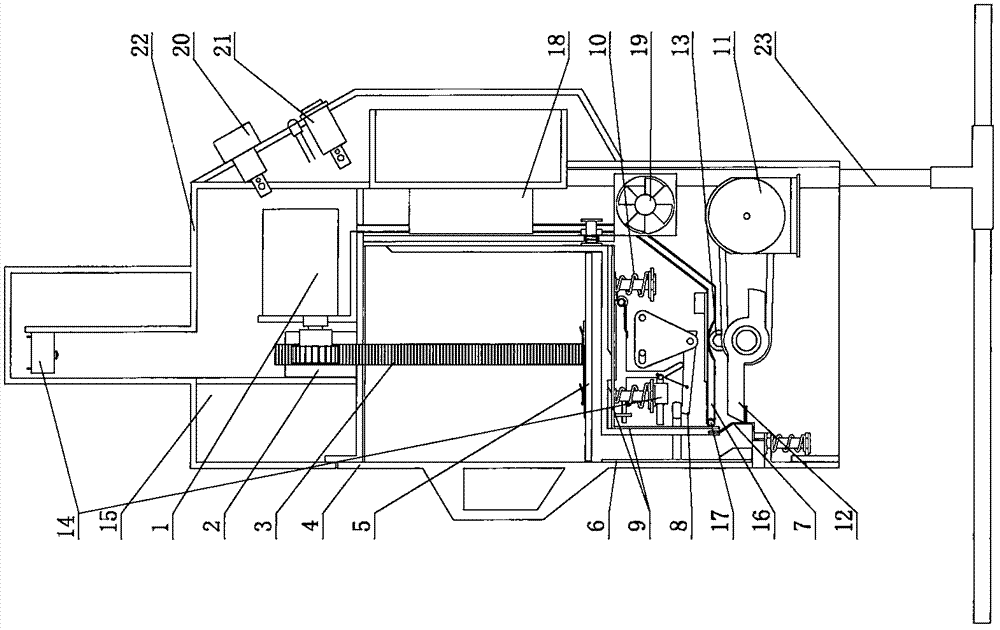

Embodiment 1

[0017] For the new multi-purpose noodle pressing device; driven by the upper motor 1, the rack 3 acting on the slider 2 moves up and down, and the vertical pressing plate 5 on the rack 3 performs the extrusion work in the barrel 4 , the food in the material barrel 4 overflows from the holes of the shaping template 7 through extrusion, when the vertical pressing plate 5 moves to the base 9, the spring 10 starts to shrink, the base 9 starts to move down, and the horizontal pushing force acting on both sides of the base 9 simultaneously The pull rod 8 starts to move horizontally, and drives the horizontal pressing plate 6 to carry out extrusion work. When the horizontal pressing plate 6 moves to the shaping template 7, the food in the material bucket 4 has been emptied at this time, and the material bucket 4 will continue to move horizontally until it is touched. Reset button 14; when the reset button 14 is touched, the upper motor 1 immediately turns to work reversely, so that th...

Embodiment 2

[0019] For the novel multi-purpose noodle pressing device; as described in embodiment 1, when starting the upper motor 1, open the lower motor speed control switch 20 at the same time, start the lower motor 11, make the rotary knife 12 and the pusher 13 start to rotate, when push When the presser 13 collides with the flexible pipe 16 connected from the water tank 15, the water will spray out from the water nozzle 17, and spray to the rotary knife 12, so that the rotating rotary knife is kept moist, and can quickly break away from the cut food, and the The cut and shaped food is directly put into the pot for steaming.

Embodiment 3

[0021] For the novel multi-purpose noodle pressing device; in the prior art, the processing of food is through continuous work such as stirring, kneading and extruding, and the food is overflowed and formed from the hole of the stereotyped template; in combination with the prior art and the existing cooking device, As described in embodiment 2, the food overflowing from the shaped template hole is cut by a knife, and the knife is kept in a wet state by spraying water to achieve the purpose of continuous cutting, and the cut and formed food is steamed in a pot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com