Pelletizing method for sticky materials

A material and viscous technology, applied in the field of granulation of viscous materials, can solve the problems of high sugar content, high viscosity and long time consumption of materials, achieve uniform particles, reduce granulation cycle and improve granulation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

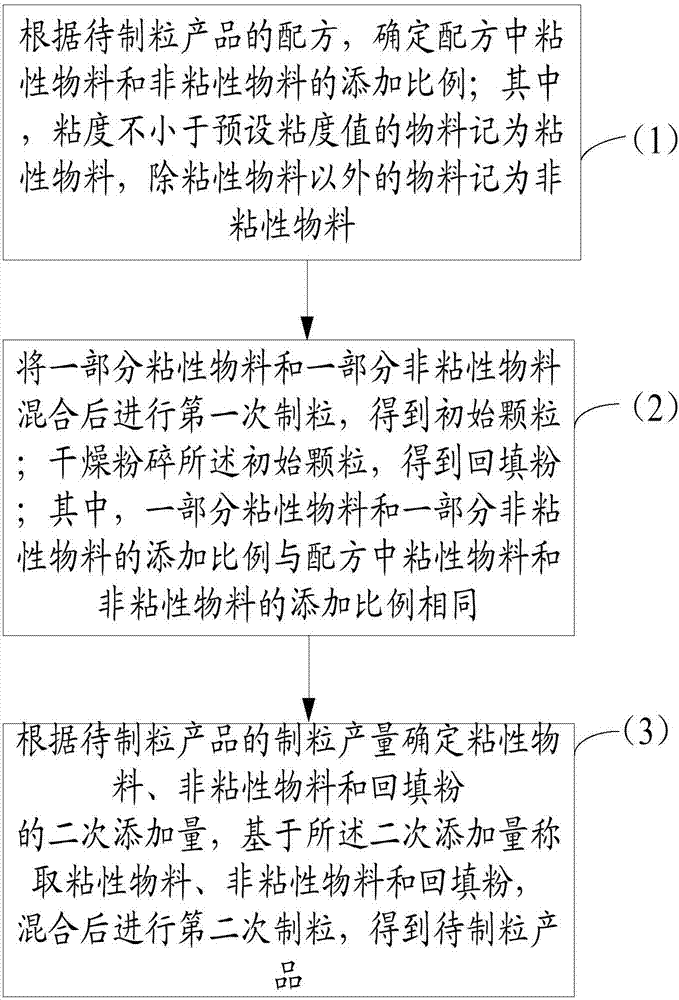

Method used

Image

Examples

Embodiment 1

[0034] Prepare 160kg of a certain granule, according to the formula requirements, take by weighing 44.5kg of extract, 5.6kg of amber powder, 23.7kg of dextrin, 23.8kg of β-cyclodextrin, and 62.4kg of sucrose powder. First add amber powder, dextrin, β-cyclodextrin, and sucrose powder to the material pot of the wet granulator, dry mix for 3 minutes, add extract, and granulate for 2 minutes. Make preliminary granules, then dry and pulverize to make 160kg of backfill powder.

[0035] Backfill powder 40kg, weigh again extract 33.4kg, amber powder 4.2kg, dextrin 17.8kg, β-cyclodextrin 17.8kg, sucrose powder 46.8kg, amber powder, dextrin, β-cyclodextrin, sucrose powder 1. Add the backfill powder to the material pot of the wet granulator, dry mix for 3 minutes, add the extract, and granulate for 2 minutes to produce 160kg of the granule. The particle size of the prepared granule is uniform and there is no phenomenon of stepping on the pot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com