A butt welding expansion device for rectangular tube groups

A technology of expanding bracing device and rectangular tube, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of reducing labor intensity, high safety hazards, huge human and financial resources, and high processing quality requirements, so as to reduce labor intensity. , The effect of reducing safety hazards and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

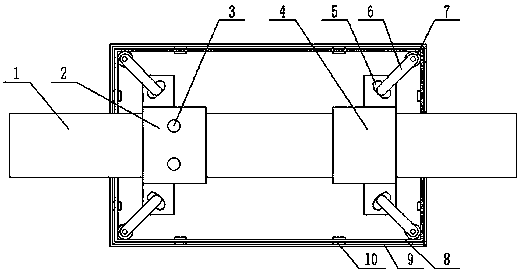

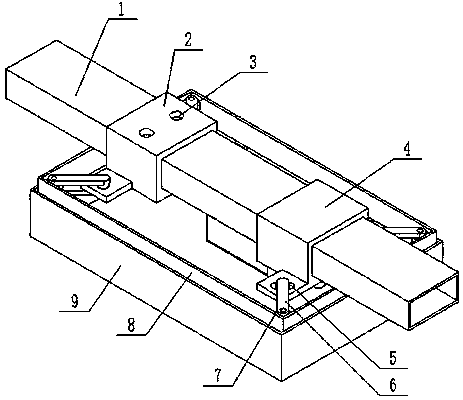

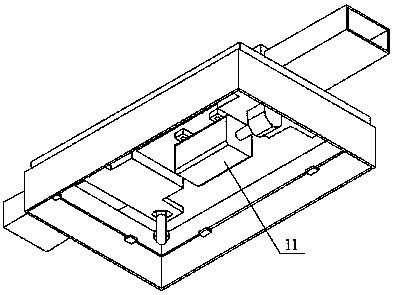

[0028] like Figure 1 to Figure 3 As shown, a rectangular pipe group butt welding expansion device includes two expansion brackets, each expansion bracket is symmetrically provided with an arc groove 5 on both sides, the center of the arc groove 5 is outward, and each arc groove 5 is There is a support leg 6 in sliding connection, one end of the support leg 6 is provided with a sliding shaft, the sliding shaft cooperates with the arc groove 5, the support leg 6 is opened, and the ends of the support legs 6 are provided with rollers 7, and each support leg 6 ends The rollers 7 on the upper part respectively abut against the four right angles of the rectangular tube 8 to be expanded. During the expansion process, the rollers 7 on the supporting legs 6 will expand the four corners, thereby indirectly st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com