Automatic screw distributing device and method an automatic screw driving device using automatic screw distributing device

A driving device and screw technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of poor market acceptance and inconvenient maintenance of the nailing device, achieve convenient maintenance, avoid wear or nail sticking problems, improve The effect of market acceptance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

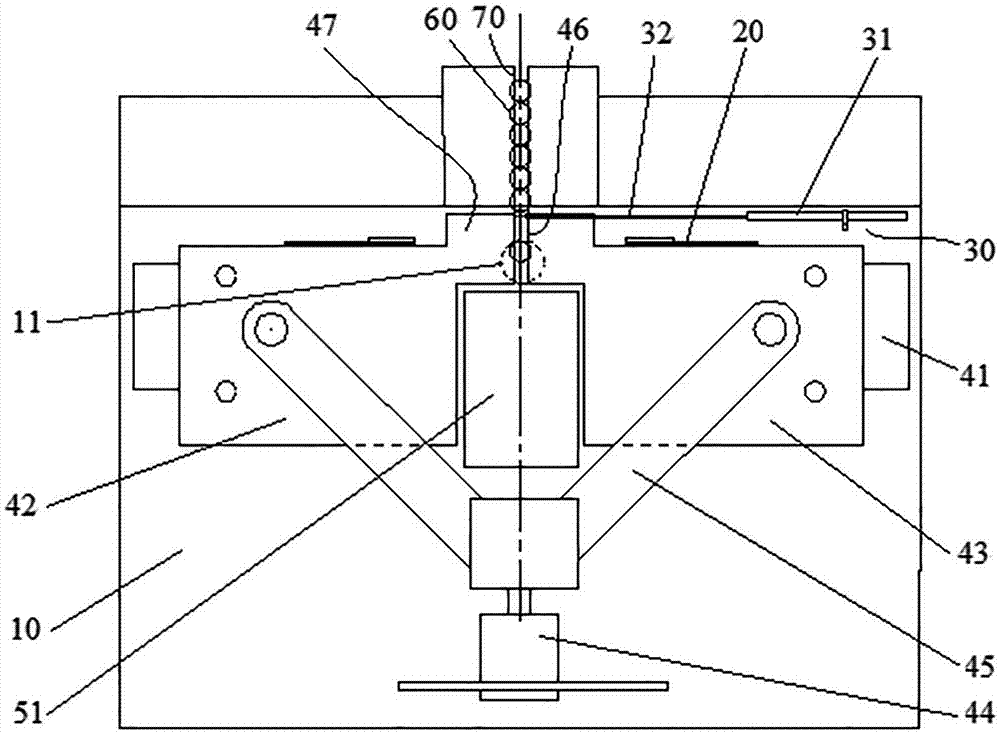

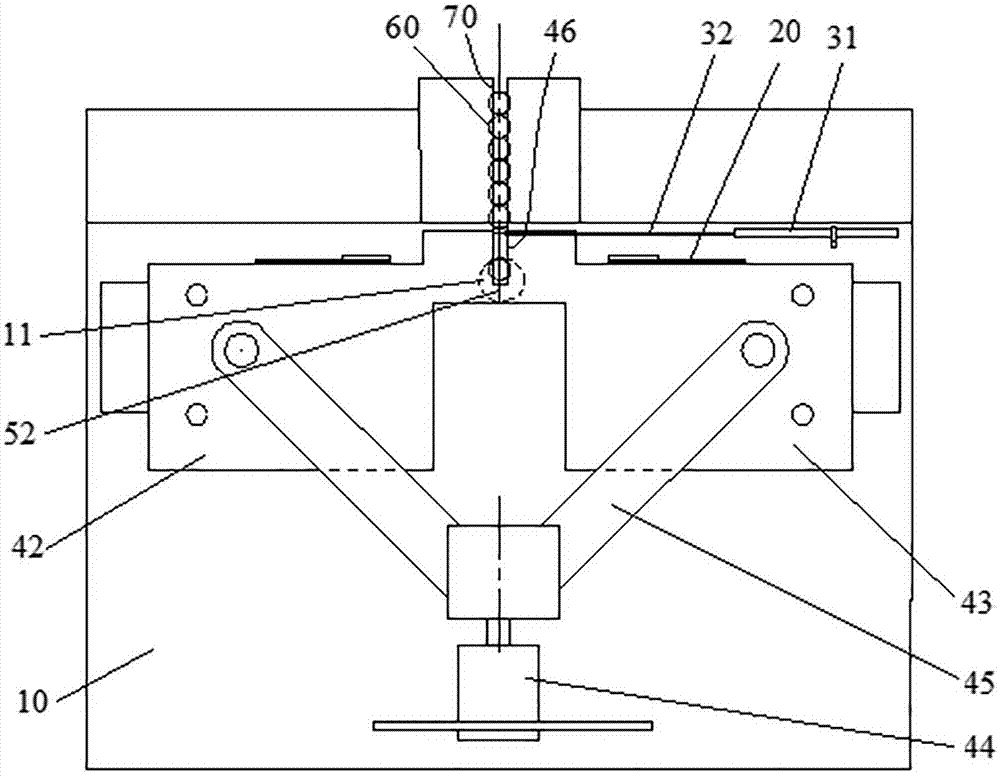

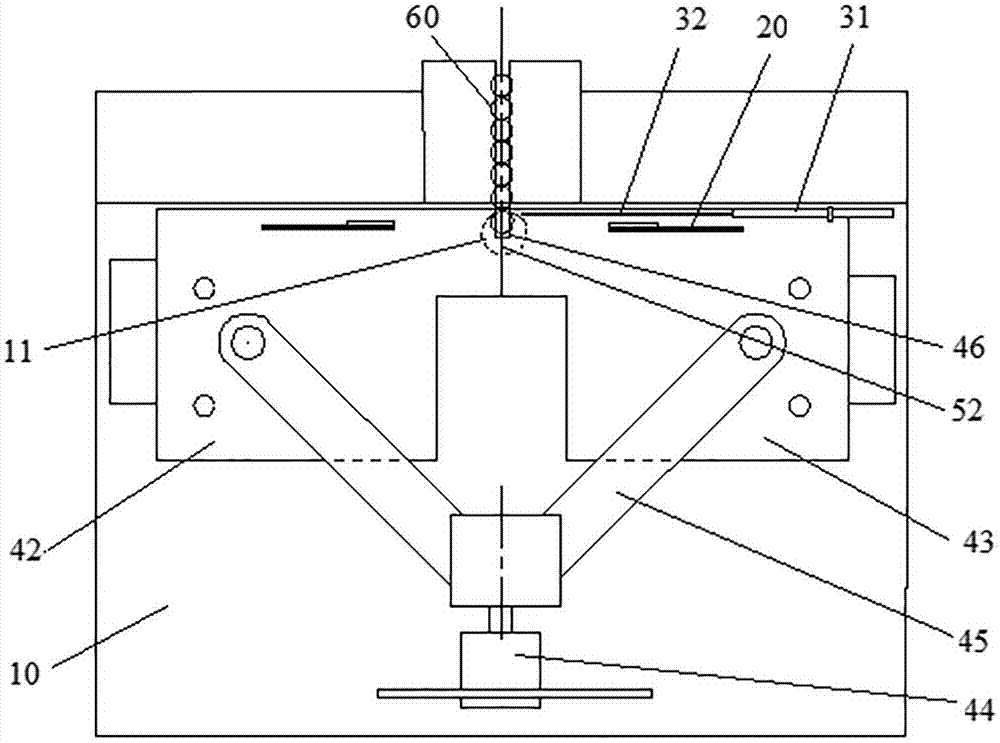

[0030] Embodiment 1 of the automatic nail dividing device among the present invention is as figure 1 As shown, the device seat 10 is included, the device seat 10 is provided with a screw sensor 20, a screw blocking device 30 and a guide rail 41 extending left and right, the guide rail 41 is equipped with a first mobile seat 42 and a second mobile seat 43 for guiding movement, and the device seat 10 is also provided with a driving cylinder 44 on the side of the first and second moving seats facing away from the butt end. Connecting rods 45 are respectively hinged, and the two connecting rods 45 are arranged symmetrically with respect to the driving cylinder 44 to form a driving device for driving the first and second moving seats to move away and approach relatively.

[0031]The first moving seat 42 and the second moving seat 43 are both plate-shaped structures. Driven by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com