Vibration feeding device

A vibrating plate and auxiliary blanking technology, which is applied in the field of blanking devices, can solve the problems of not being able to pull the hopper, and the friction of the hopper is large, so as to reduce the operating intensity, ensure stability, and ensure product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

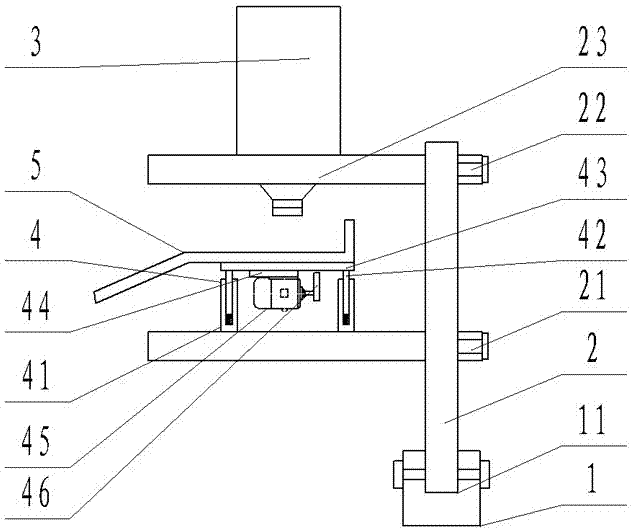

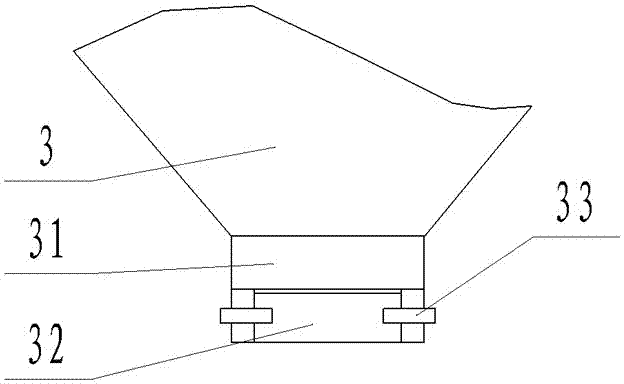

[0014] see Figure 1-2 , a vibration blanking device, including a base 1, a support rod 2 and a vibration auxiliary blanking device 4, a square slot 11 is provided above the base 1, positioning holes are provided around the square slot 11, and positioning holes are positioned in the square slot 11. The cooperation of the hole and the bolt is provided with a support rod 2; the support rod 2 is provided with a first positioning part 21 and a second positioning part 22, the first positioning part 21 is located above the second positioning part 22, the first positioning part 21 and the second positioning part 22 The second positioning part 22 is provided with movable holes, and positioning holes are arranged around the movable holes. The first positioning part 21 is additionally provided with a socket 23, and the periphery of the socket 23 is also prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com