A kind of nitrogen, boron doped porous carbon for supercapacitor electrode and preparation method thereof

A supercapacitor and porous carbon technology, applied in hybrid capacitor electrodes, chemical instruments and methods, carbon compounds, etc., can solve the problems of unsuitable supercapacitor electrode materials, low electrochemical activity, etc., and achieve broad market application prospects, high ratio Capacitance, the effect of improving pseudocapacitive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

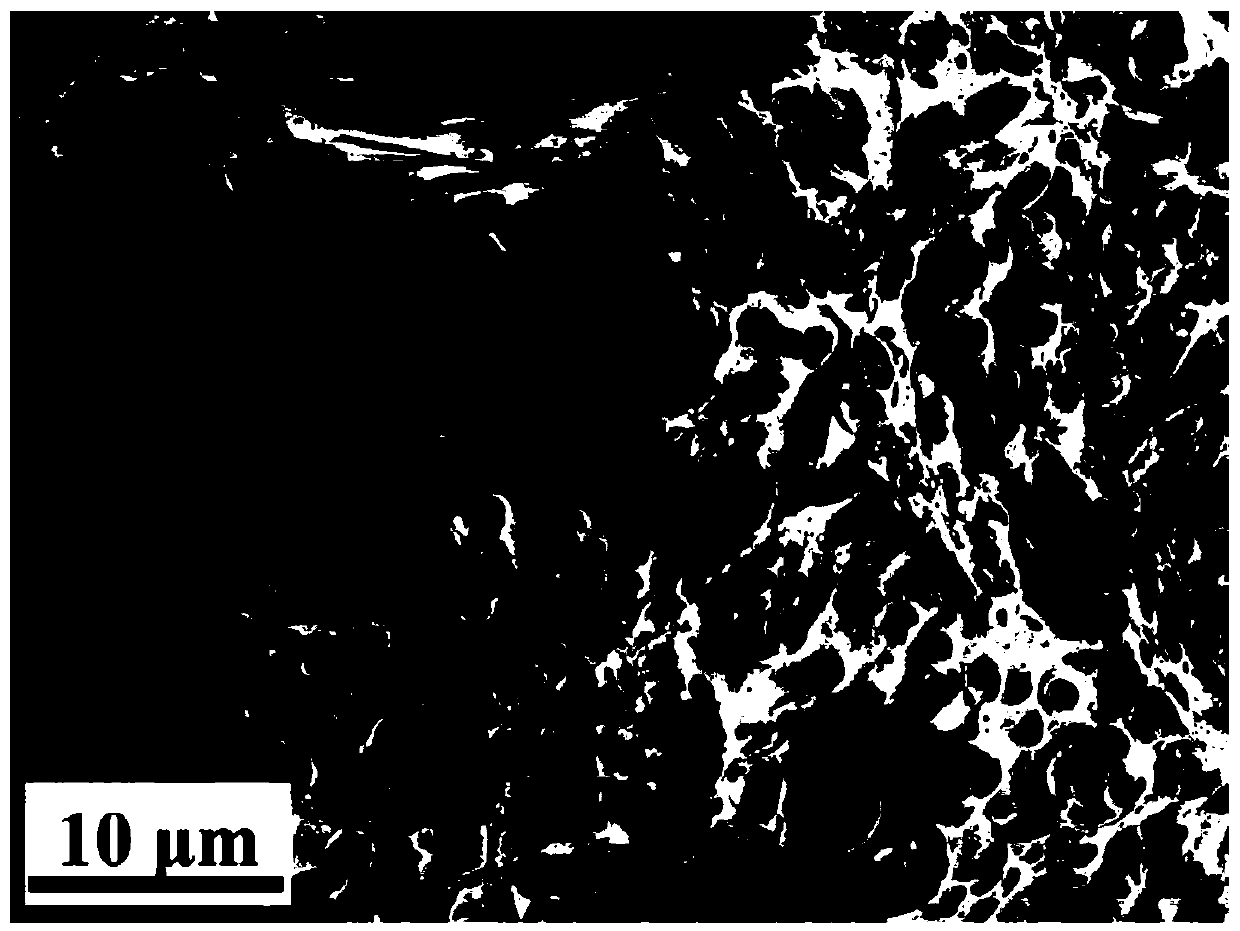

[0047] (1) intercept the reed stalk, peel it, dry it, adopt a tissue masher to pre-crumble it, use deionized water as a dispersant, and adopt a planetary ball mill to further ball-mill the pre-broken reed stalk, and the rotating speed is 500 rpm Minutes, ball milling time is 24 hours.

[0048] (2) The slurry after ball milling was centrifuged at a speed of 5000 rpm, and the sediment was alternately washed three times with deionized water and absolute ethanol, and dried at 50 degrees Celsius to obtain pretreated reed stalk powder.

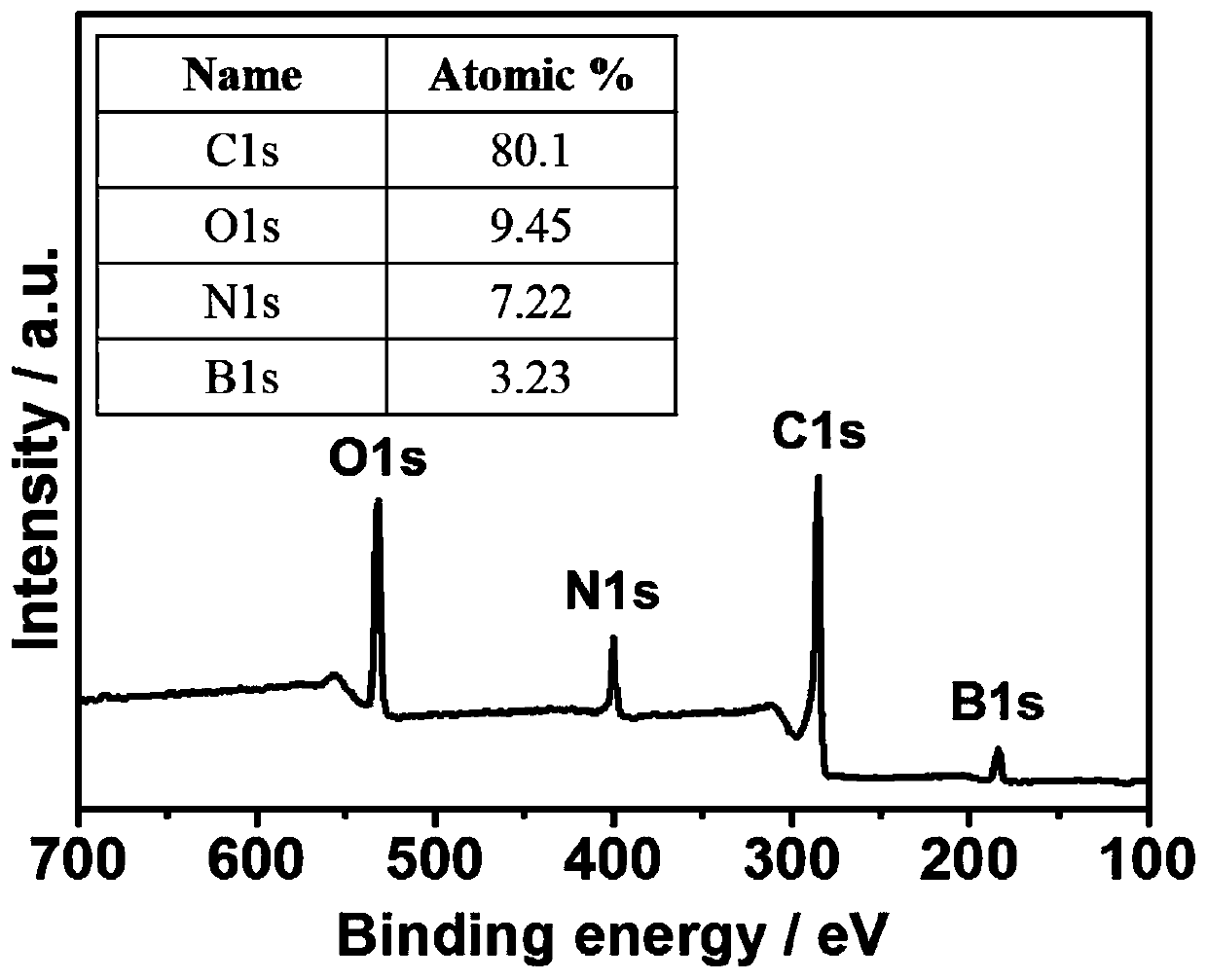

[0049] (3) Weigh reed stalk powder, urea ammonium nitrogen fertilizer (nitrogen ≥ 30%, China Salt Anhui Hongsifang Co., Ltd.), boron fertilizer (sodium borate ≥ 99%, boron-containing ≥15%, Anhui Nongwang Agricultural Science and Technology Development Co., Ltd.) was dispersed in deionized water, heated at 160 degrees Celsius for 12 hours in a hydrothermal reaction kettle, and the precipitate was repeatedly washed alternately with deionized water and...

Embodiment 2

[0059] (1) intercept the reed stalk, peel it, dry it, adopt a tissue masher to pre-crumble it, use deionized water as a dispersant, and adopt a planetary ball mill to further ball-mill the pre-broken reed stalk, and the rotating speed is 500 rpm Minutes, ball milling time is 24 hours.

[0060] (2) The slurry after ball milling was centrifuged at a speed of 5000 rpm, and the sediment was alternately washed three times with deionized water and absolute ethanol, and dried at 50 degrees Celsius to obtain pretreated reed stalk powder.

[0061] (3) Take reed stalk powder, nitrogen fertilizer, boron fertilizer, and potassium hydroxide according to the mass ratio of 1:2:2:3, add an appropriate amount of deionized water to the system after mixing, continue to stir until it becomes a paste, and after 50 Dry at °C, transfer to a tube furnace, pass an argon atmosphere, first raise the temperature to 300 °C at a rate of 2 °C / min and keep it warm for 1 hour, then raise the temperature to 70...

Embodiment 3

[0065] (1) Plane the fresh and alive reed that contains root hair, cultivate after 15 days in the nitrogenous fertilizer that contains 5% mass ratio and the boron fertilizer mixed solution of 5% mass ratio, intercept reed stalk, peel, adopt tissue masher to its For pre-crushing, deionized water is used as a dispersant, and the pre-broken reed stalks are further ball-milled with a planetary ball mill at a speed of 500 rpm, and the ball-milling time is 24 hours.

[0066] (2) The slurry after ball milling was centrifuged at a speed of 5000 rpm, and the sediment was alternately washed three times with deionized water and absolute ethanol, and dried at 50 degrees Celsius to obtain pretreated reed stalk powder.

[0067] (3) Weigh the reed stalk powder and potassium hydroxide according to the mass ratio of 1:3, mix them evenly, add an appropriate amount of deionized water to the system, continue to stir until it becomes a paste, dry it at 50 degrees Celsius, and transfer it to a tube ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com