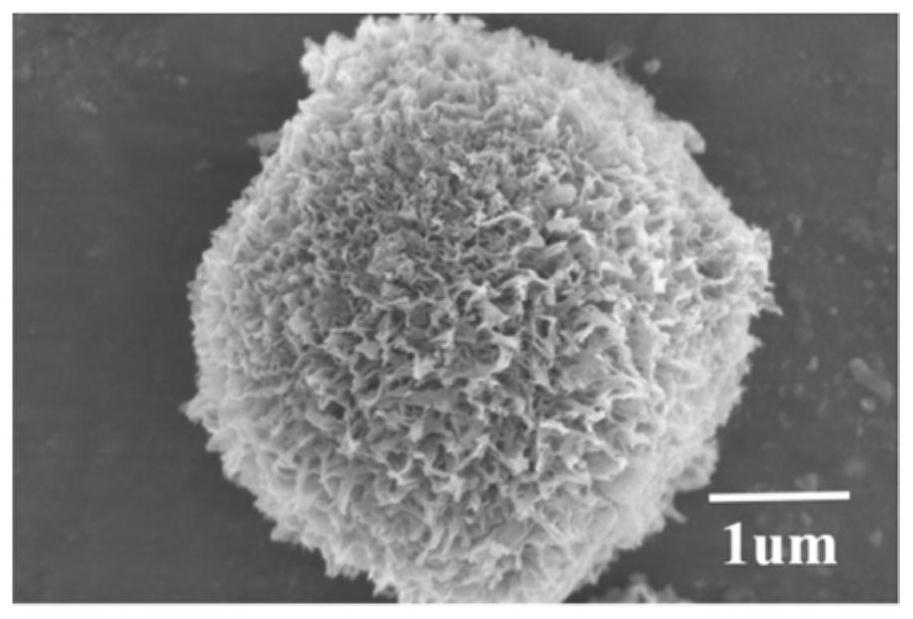

Preparation method of sea urchin-shaped titanium dioxide multistage microsphere negative electrode material

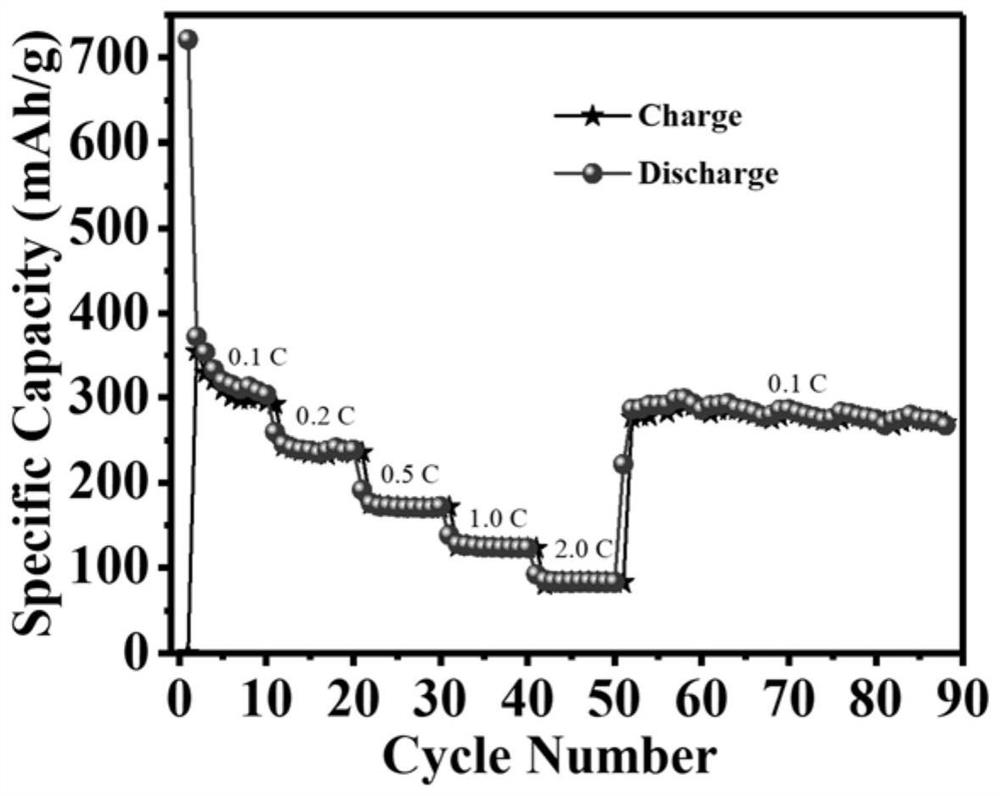

A technology of titanium dioxide and negative electrode material, applied in the direction of titanium dioxide, titanium oxide/hydroxide, negative electrode, etc., can solve the problems of slow diffusion of lithium ions, poor kinetic reaction, poor cycle performance, etc., to achieve non-toxic and harmless raw materials, The effect of improving pseudocapacitance characteristics and controllable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of a sea urchin-like titanium dioxide multi-level microsphere negative electrode material, comprising the following steps:

[0029] 1) Add 1.8 mL of oleylamine dropwise to a beaker containing 200 mL of ethanol, place the beaker on a magnetic stirring table, and stir for 20 minutes;

[0030] 2) Slowly add 4.5mL tetra-n-butyl titanate to the solution obtained in step 1), and stir for 20min at the same time; after stirring evenly, add 0-10.5mL tetraethyl orthosilicate and 0.8mL H 2 0, stirred for 2h, took off the beaker and left it in the dark for 12h, and obtained a white precipitate after washing three times with deionized water;

[0031] 3) Dry the white precipitate obtained in step 2) in an oven at 60°C for 12h, and then calcinate it in a muffle furnace at 450°C for 2h to obtain TiO 2 / SiO 2 Precursor;

[0032] 4) with the TiO obtained in step 3) 2 / SiO 2 Take 0.2g of the precursor and disperse it in 2mol L -1 , 50mL of KOH aqueous solution, ...

Embodiment 1

[0038] 1) Add 1.8 mL of oleylamine dropwise to a beaker containing 200 mL of ethanol, place the beaker on a magnetic stirring table, and stir for 20 minutes;

[0039] 2) Slowly add 4.5mL tetra-n-butyl titanate to the solution obtained in step 1), and stir for 20min at the same time; add 0.8mL H 2 0, stirred for 2h, left standstill for 12h after taking off the beaker, obtained white precipitate after washing three times with deionized water;

[0040] 3) Dry the white precipitate obtained in step 2) in an oven at 60°C for 12h, and then calcinate it in a muffle furnace at 450°C for 2h to obtain TiO 2 / SiO 2 Precursor;

[0041] 4) with the TiO obtained in step 3) 2 / SiO 2 Take 0.2g of the precursor and disperse it in 50mL, the concentration is 2mol L -1 KOH aqueous solution, after stirring, transfer it to a 100mL reaction kettle, and conduct a hydrothermal reaction at 100°C for 24h;

[0042] 5) Disperse the precipitate collected in step 4) in 200mL with a concentration of 0....

Embodiment 2

[0046] 1) Add 1.8 mL of oleylamine dropwise to a beaker containing 200 mL of ethanol, place the beaker on a magnetic stirring table, and stir for 20 minutes;

[0047] 2) Slowly add 4.5mL tetra-n-butyl titanate to the solution obtained in step 1), and stir for 20min at the same time; after stirring evenly, add 3mL tetraethyl orthosilicate and 0.8mL H 2 0, stirred for 2h, took off the beaker and left it in the dark for 12h, and obtained a white precipitate after washing three times with deionized water;

[0048] 3) Dry the white precipitate obtained in step 2) in an oven at 60°C for 12h, and then calcinate it in a muffle furnace at 450°C for 2h to obtain TiO 2 / SiO 2 Precursor;

[0049] 4) with the TiO obtained in step 3) 2 / SiO 2 Disperse 0.2 g of the precursor in 50 mL of KOH aqueous solution with a concentration of 2 mol L-1, stir evenly, transfer it to a 100 mL reaction kettle, and conduct a hydrothermal reaction at 100 °C for 24 h;

[0050] 5) Disperse the precipitate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com