A kind of expanded interlayer spacing microcrystalline graphite material and its preparation method and application in sodium ion battery

A technology of microcrystalline graphite and interlayer spacing, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., to achieve the effects of long cycle stability, high tap density, and improved rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

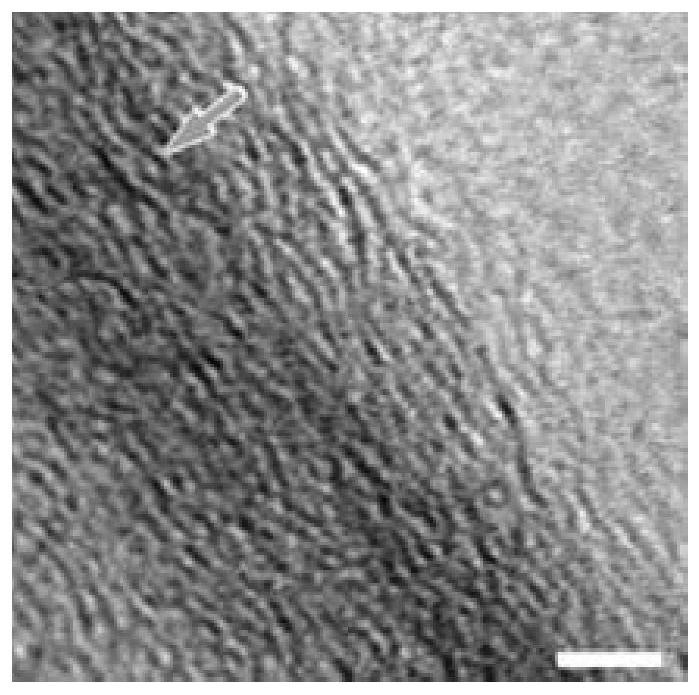

Image

Examples

Embodiment 1

[0043] Take 20g of microcrystalline graphite and add it to the crusher for cutting and crushing, and then sieve through a 200-mesh sieve to obtain microcrystalline graphite powder; the volume ratio of industrial grade hydrochloric acid: industrial grade hydrofluoric acid: deionized water is 5:3:2 Prepare 100ml of mixed acid solution, pour microcrystalline graphite powder into the mixed acid solution, heat and stir with a magnetic stirrer, the stirring temperature is 80°C, and the mixed acid treatment time is 12h; filter and wash with deionized water for 3 times, and then use 100ml of absolute ethanol was used for ultrasonic cleaning to remove the ash impurities remaining in the micropores. The ultrasonic oscillation time was 20 minutes; then filtered and washed with deionized water for 3 times; placed in an oven at 60°C for 6 hours to obtain purified microcrystals Graphite powder; the microcrystalline graphite obtained is mixed with 6g sodium nitrate, 160g (100mL) concentrated ...

Embodiment 2

[0046] Take 20g of microcrystalline graphite and add it to the crusher for cutting and crushing, and then sieve through a 200-mesh sieve to obtain microcrystalline graphite powder; the volume ratio of industrial grade hydrochloric acid: industrial grade hydrofluoric acid: deionized water is 5:3:2 Prepare 100ml mixed acid solution, pour the microcrystalline graphite powder into the mixed acid solution, heat and stir with a magnetic stirrer, the stirring temperature is 70°C, and the mixed acid treatment time is 18h; filter and wash with deionized water for 3 times, and then use 100ml of absolute ethanol was used for ultrasonic cleaning to remove the ash impurities remaining in the micropores. The ultrasonic oscillation time was 20 minutes; then filtered and washed with deionized water for 3 times; placed in an oven at 60°C for 6 hours to obtain purified microcrystals Graphite powder; the obtained microcrystalline graphite is mixed with 5g sodium nitrate, 140g (87.5mL) concentrate...

Embodiment 3

[0049] Take 30g of microcrystalline graphite and add it to the crusher for cutting and crushing, and then sieve through a 200-mesh sieve to obtain microcrystalline graphite powder; the volume ratio of industrial grade hydrochloric acid: industrial grade hydrofluoric acid: deionized water is 4:4:2 Prepare 100ml mixed acid solution, pour the microcrystalline graphite powder into the mixed acid solution, heat and stir with a magnetic stirrer, the stirring temperature is 90°C, and the mixed acid treatment time is 12h; filter and wash with deionized water for 3 times, and then use 100ml of absolute ethanol was used for ultrasonic cleaning to remove the ash impurities remaining in the micropores. The ultrasonic oscillation time was 20 minutes; then filtered and washed with deionized water for 3 times; placed in an oven at 60°C for 6 hours to obtain purified microcrystals Graphite powder; the microcrystalline graphite obtained is mixed with 4.2g sodium nitrate, 120g (75mL) concentrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com