A kind of sodium ion battery sulfur-doped molybdenum selenide negative electrode composite material and preparation method thereof

A sodium-ion battery and composite material technology, applied in the field of sodium-ion batteries, can solve problems such as difficult to meet the requirements of sodium-ion batteries, unsatisfactory rate performance, complicated preparation methods, etc., to achieve increased reaction interface, good material conductivity and mechanical properties The effect of simple performance and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Add 0.8g of ammonium molybdate, 0.1g of carbon nanotubes, 0.33g of potassium borohydride and 0.1g of polyvinylpyrrolidone into the aqueous solution, and react under hydrothermal conditions at 185°C for 30h to obtain molybdenum oxide / carbon composite materials.

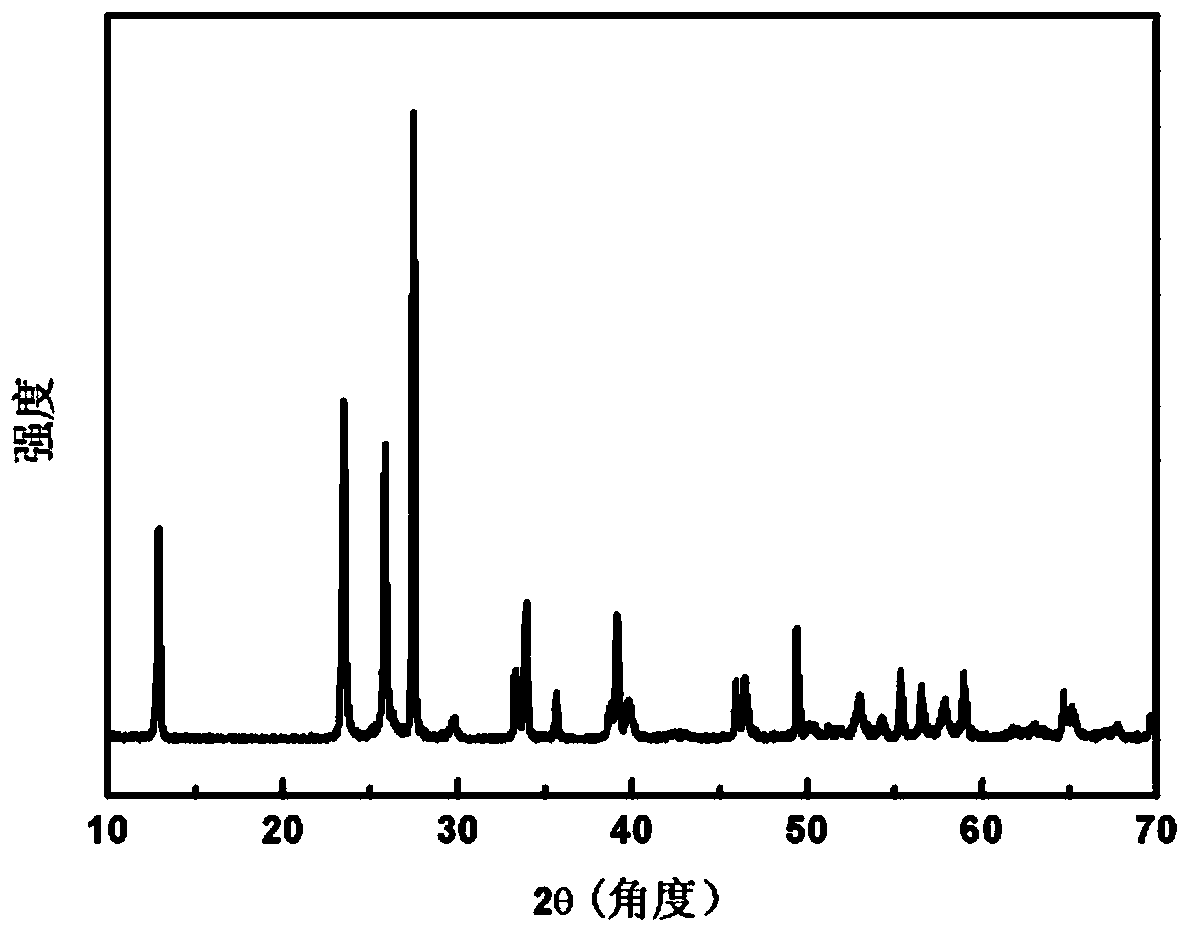

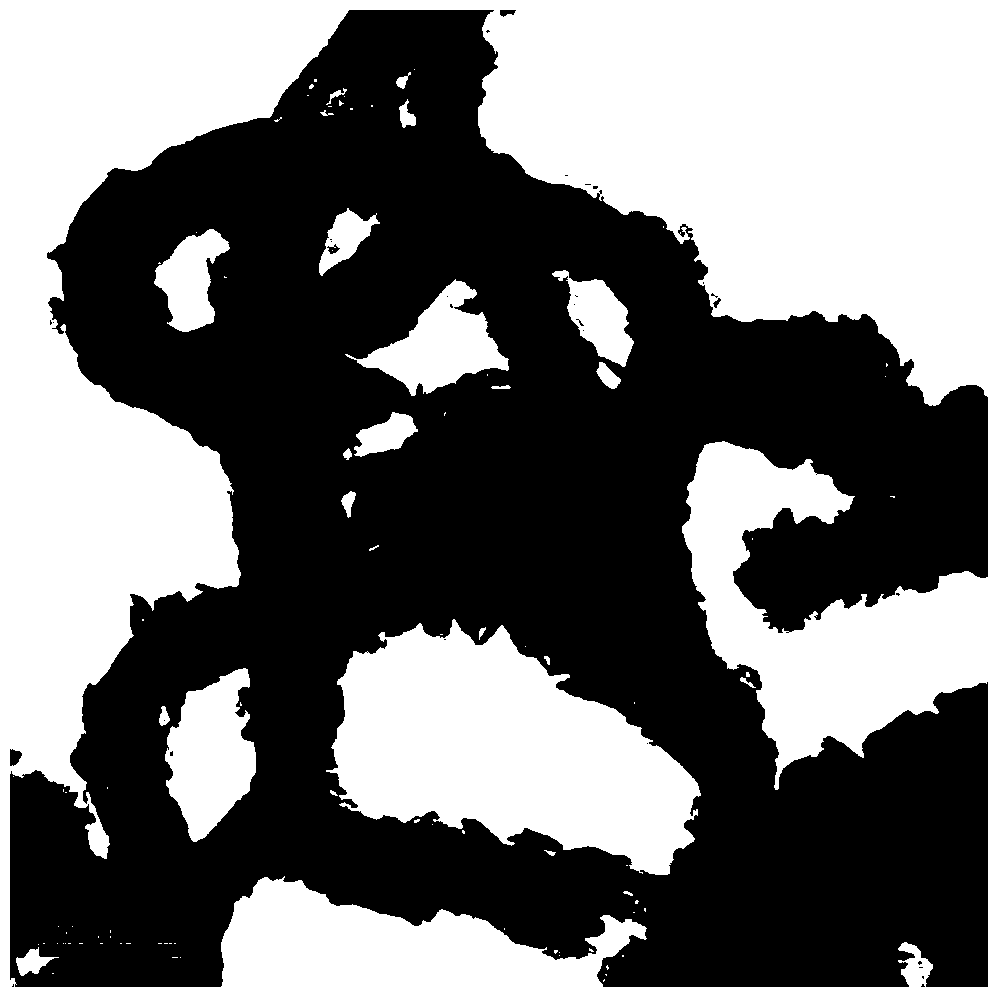

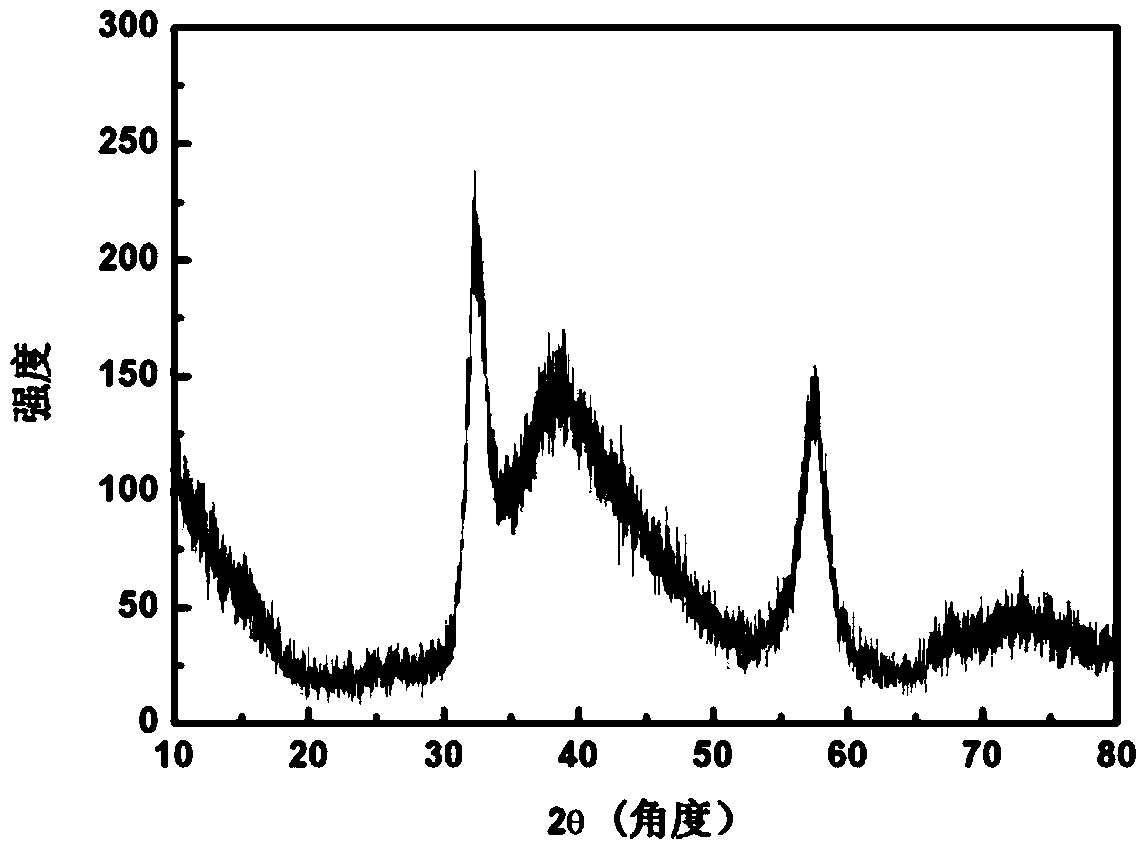

[0052] Then add 0.5 molybdenum oxide / carbon composite material into 40ml alcohol solution and ultrasonically disperse for 40min to obtain a dispersion liquid, add 12ml hydrazine hydrate, 0.16g selenium powder and 0.08g thiourea to the dispersion liquid and fully dissolve them, Reaction in the reactor for 24h. After the reaction product is washed and dried at 70°C, the precursor of the sulfur-doped molybdenum selenide / carbon composite material is obtained. After annealing at 600°C for 6 hours under the condition of argon atmosphere, the obtained composite material has a diameter of 60-100nm (that is, the diameter of carbon nanotubes with sulfur-doped molybdenum selenide is 60-100nm), in which sulfur-doped flake s...

Embodiment 2

[0062] Add 0.45g of sodium molybdate, 0.15g of carbon nanotubes, 0.33g of sodium borohydride and 0.07g of sodium dodecylbenzenesulfonate into the aqueous solution, and react under hydrothermal conditions at 195°C for 28 hours to obtain molybdenum oxide / carbon composite material. Then 0.4g of molybdenum oxide / carbon composite material was added into 40ml of alcoholic solution and ultrasonically dispersed for 40min to obtain a dispersion. In said dispersion, 11ml of n-octylamine, 0.2g of selenium dioxide and 0.057g of sulfur powder were added and fully dissolved. React in a reactor at 205°C for 25h. After the reaction product is washed and dried at 70°C, the precursor of the sulfur-doped molybdenum selenide / carbon composite material is obtained. After annealing at 600°C for 7 hours in a nitrogen atmosphere, a composite material with a diameter of 100-120nm (that is, a carbon nanotube with sulfur-doped molybdenum selenide has a diameter of 100-120nm), in which sulfur-doped molyb...

Embodiment 3

[0066] Add 0.72g of sodium molybdate, 0.08g of carbon nanotubes, 0.73g of sodium sulfite, and 0.09g of sodium dodecylbenzenesulfonate into the aqueous solution, and react under hydrothermal conditions at 195°C for 28 hours to obtain molybdenum oxide / carbon composites . Then 0.48g of molybdenum oxide / carbon composite material was added into 40ml of alcohol solution and ultrasonically dispersed for 40min to obtain a dispersion. In the dispersion, 10ml of ethylenediamine, 0.12g of selenium powder and 0.048g of sulfur powder were added and fully dissolved. Reaction in a reactor at 190°C for 20h. After the reaction product is washed and dried at 70°C, the precursor of the sulfur-doped molybdenum selenide / carbon composite material is obtained. After annealing at 700°C for 8 hours under the inert atmosphere of helium, the diameter of the composite material is 120-140nm (that is, the diameter of carbon nanotubes with sulfur-doped molybdenum selenide is 100-120nm), and the sulfur-dope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com