Sodium ion negative electrode material, preparation method and sodium ion battery

A technology of negative electrode material and sodium ion, applied in the field of negative electrode active material and preparation of sodium ion battery, can solve the problems of low material utilization rate, low electrochemical performance, battery capacity attenuation, etc. Improved, improved cycle stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

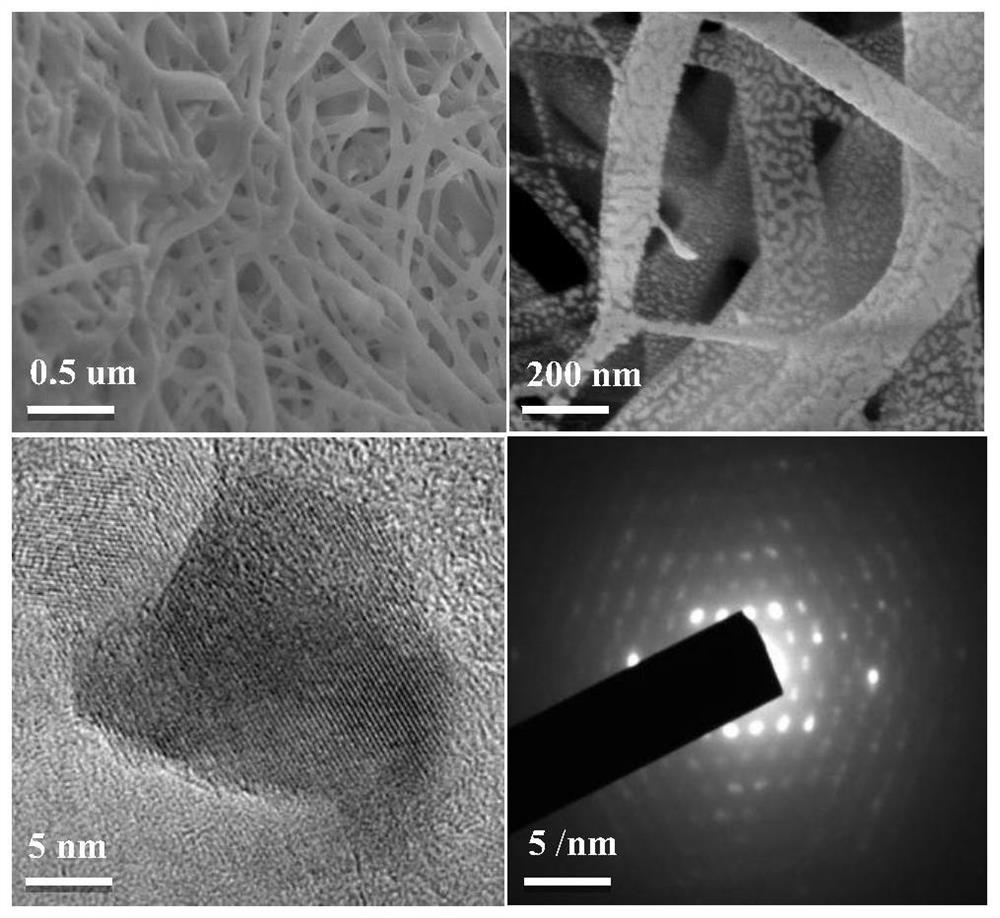

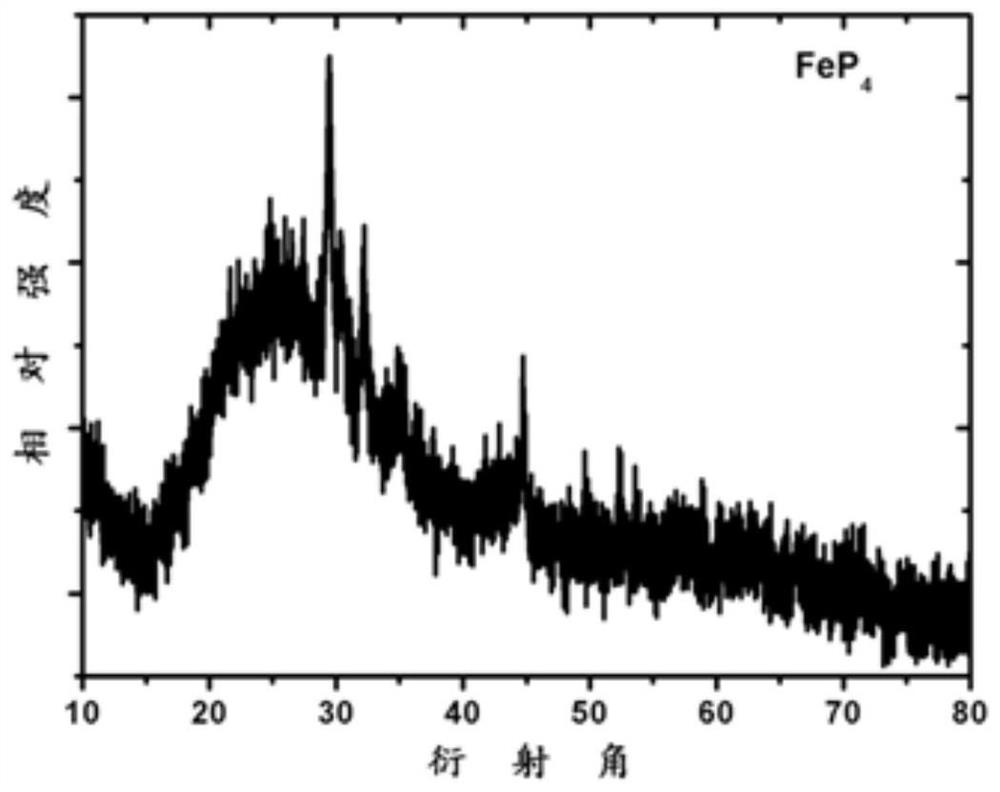

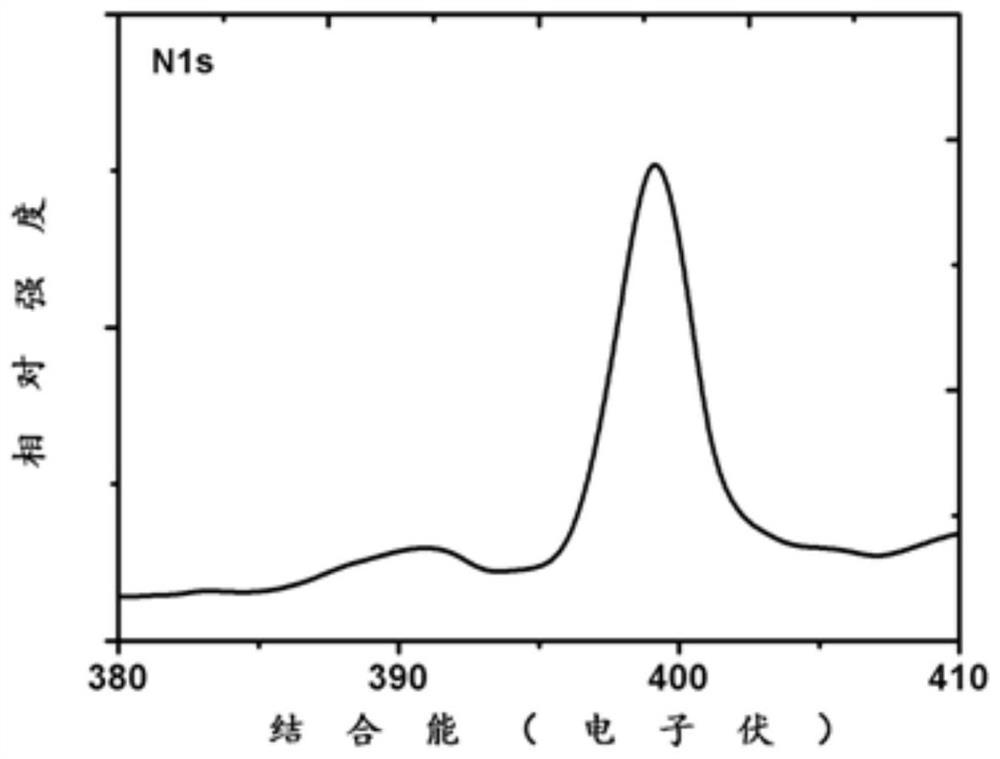

Image

Examples

Embodiment 1

[0033] With 1.0g urea, 5mmol ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O), 4 mmol triphenylphosphine and 0.2 g PMMA (polymethyl methacrylate) were added in batches to 10 mL of DMF (N-N-dimethylformamide), stirred and dissolved, and stirred thoroughly for 24 hours to form a precursor solution A , and then add 0.9g PVP (polyvinylpyrrolidone) into the precursor solution A and stir evenly, and continue to stir for 24 hours to obtain a transparent solution B;

[0034] Inject the transparent solution B into the needle tube, use a 18G single-core needle, set the experimental temperature range to 40°C, and the experimental humidity range to 30%; the positive voltage is 17kV, the negative voltage is -3kV, and the injection speed is 0.06mm / min. The target material is obtained by spinning, and the target material is removed from the collector, placed in a 50°C oven to dry overnight, and then heat-treated. First, the sample is placed in a tube furnace and heated in air at 300°C for 1...

Embodiment 2

[0039] With 1.5g urea, 4mmol copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2O) and 0.3g PMMA (polymethyl methacrylate) were added in batches to 10mL of DMF (N-N-dimethylformamide), stirred and dissolved, and stirred thoroughly for 24h to form precursor solution A, and then 0.8g PVP (polyvinylpyrrolidone) was added to the precursor solution A and stirred evenly, and the transparent spinning solution B was obtained after continuous stirring for 24 hours;

[0040] Add 4mmol triphenylphosphine and 0.5g PMMA (polymethyl methacrylate) into 10mL DMF (dimethylformamide) in batches, stir and dissolve for 24h, and form a transparent precursor solution C after fully dissolving, and then Add 0.8g PVP (polyvinylpyrrolidone) into the precursor solution C and stir for 24 hours until a transparent spinning solution D is obtained;

[0041] Inject solution B and solution D into two needle tubes respectively for synchronous electrospinning, using a 18G needle with the same core, the inner core i...

Embodiment 3

[0043] Add 2.0g of urea, 6mmol of antimony trichloride, 4mmol of triphenylphosphine and 1.5g of PMMA (polymethyl methacrylate) into 10mL of DMF (N-N-dimethylformamide) in batches, and stir to dissolve. After fully stirring for 24 hours, precursor solution A was formed, then 1.5g PAN (polyacrylonitrile) was added to precursor solution A and stirred evenly, and transparent solution B was obtained after continuous stirring for 24 hours;

[0044] Inject the transparent solution B into the needle tube, use a 18G single-core needle, set the experimental temperature range to 50°C, and the experimental humidity range to 40%; the positive voltage is 30kV, the negative voltage is -1kV, and the injection speed is 0.06mm / min. The target material is obtained by spinning, and the target material is removed from the collector, placed in a 50°C oven to dry overnight, and then heat-treated. First, the sample is placed in a tube furnace and heated in air at 200°C for 1 hour. Shape the fiber sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com