Preparation method and application of MoS2 quasi-quantum dot/nitrogen-sulfur co-doped biomass carbon composite nanomaterial

A composite nanomaterial, nitrogen-sulfur co-doping technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as poor stability and poor electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

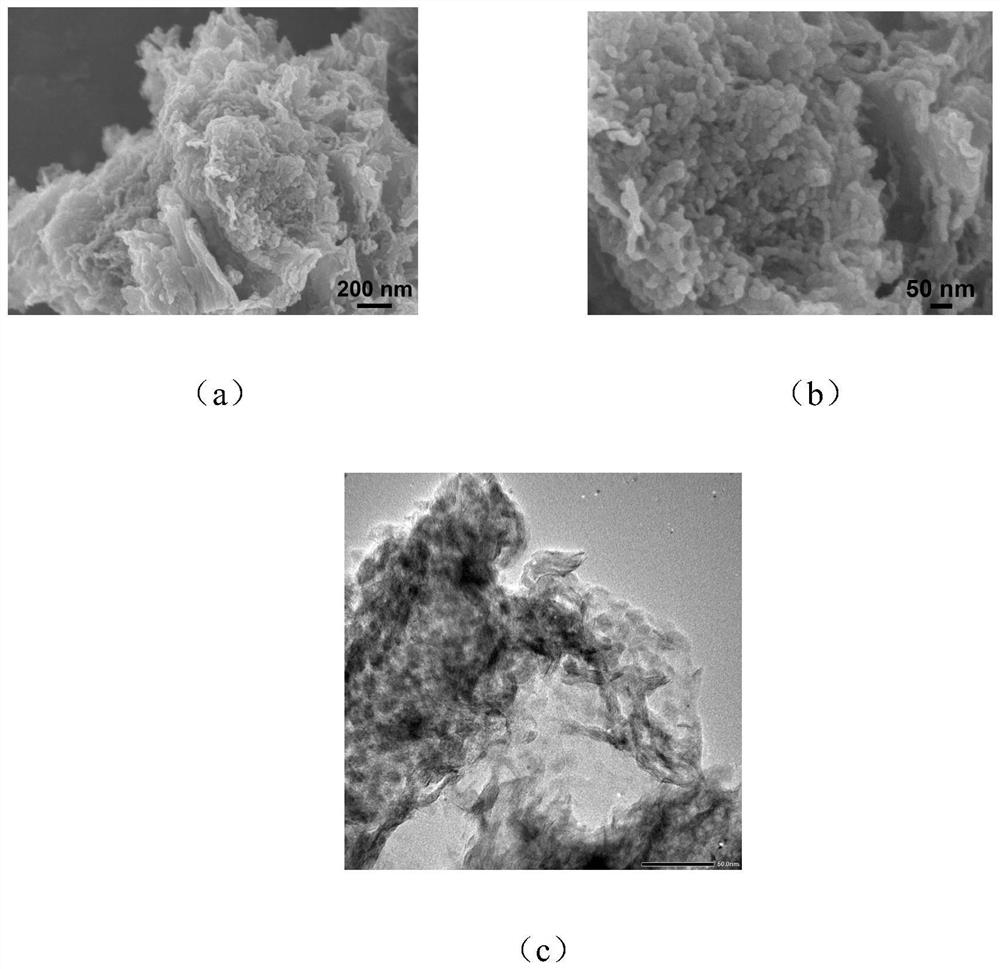

[0030] A kind of MoS 2 The preparation method of quasi-quantum dot / nitrogen-sulfur co-doped biomass carbon composite nanomaterial comprises the following steps:

[0031] Step 1: Preparation of nitrogen-doped carbon nanomaterials

[0032] 1) 20 g of cleaned lobster shells were placed in a tube furnace, and heated at 5°C min under the condition of argon gas. -1 The heating rate is raised from room temperature to 550°C for carbonization, and after holding for 1 hour, it is cooled to room temperature with the furnace;

[0033] 2) Disperse the carbonized lobster shell in 100mL deionized water, and use a concentration of 0.2mol L under the condition of magnetic stirring -1 Treat with hydrochloric acid until no bubbles are generated, and adjust to pH=7.0. cleaning and filtering the filtered product and freeze-drying to obtain nitrogen-doped carbon nanomaterials;

[0034] Step 2: MoO 3 / Preparation of Nitrogen-doped Carbon Precursor

[0035] Doping carbon and MoO with nitrogen ...

Embodiment 2

[0042] A kind of MoS 2 The preparation method of quasi-quantum dot / nitrogen-sulfur co-doped biomass carbon composite nanomaterial comprises the following steps:

[0043] Step 1: Preparation of nitrogen-doped carbon nanomaterials

[0044] 1) 25 g of cleaned lobster shells were placed in a tube furnace, and heated at 6°C min under the condition of argon gas. -1 The heating rate is raised from room temperature to 600 ° C for carbonization, and after holding for 1.5 hours, it is cooled to room temperature with the furnace;

[0045] 2) Disperse the carbonized lobster shell in 120mL deionized water, and use a concentration of 0.4mol L under the condition of magnetic stirring -1 Treat with hydrochloric acid until no bubbles are generated, and adjust to pH=7.0. cleaning and filtering the filtered product and freeze-drying to obtain nitrogen-doped carbon nanomaterials;

[0046] Step 2: MoO 3 / Preparation of Nitrogen-doped Carbon Precursor

[0047] Doping carbon and MoO with nitr...

Embodiment 3

[0054] A kind of MoS 2 The preparation method of quasi-quantum dot / nitrogen-sulfur co-doped biomass carbon composite nanomaterial comprises the following steps:

[0055] Step 1: Preparation of nitrogen-doped carbon nanomaterials

[0056] 1) 30 g of cleaned lobster shells were placed in a tube furnace, and heated at 7°C min under the condition of argon gas. -1 The heating rate is raised from room temperature to 650°C for carbonization, and after holding for 2.0 hours, it is cooled to room temperature with the furnace;

[0057] 2) Disperse the carbonized lobster shell in 150mL deionized water, and use a concentration of 0.6mol L under the condition of magnetic stirring -1 Treat with hydrochloric acid until no bubbles are generated, and adjust to pH=7.0. cleaning and filtering the filtered product and freeze-drying to obtain nitrogen-doped carbon nanomaterials;

[0058] Step 2: MoO 3 / Preparation of Nitrogen-doped Carbon Precursor

[0059] Doping carbon and MoO with nitrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com