Preparation method of anode material for sodium-ion batteries

A sodium-ion battery and positive electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor structure and thermal stability, low voltage platform, etc. The method is simple, repeatable, and operable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

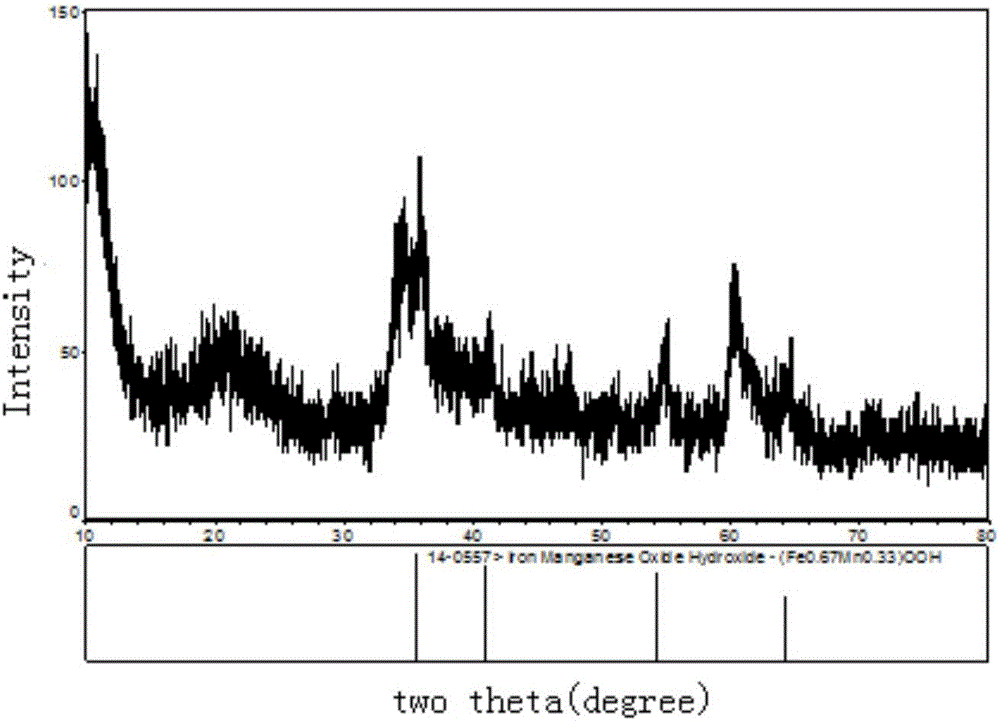

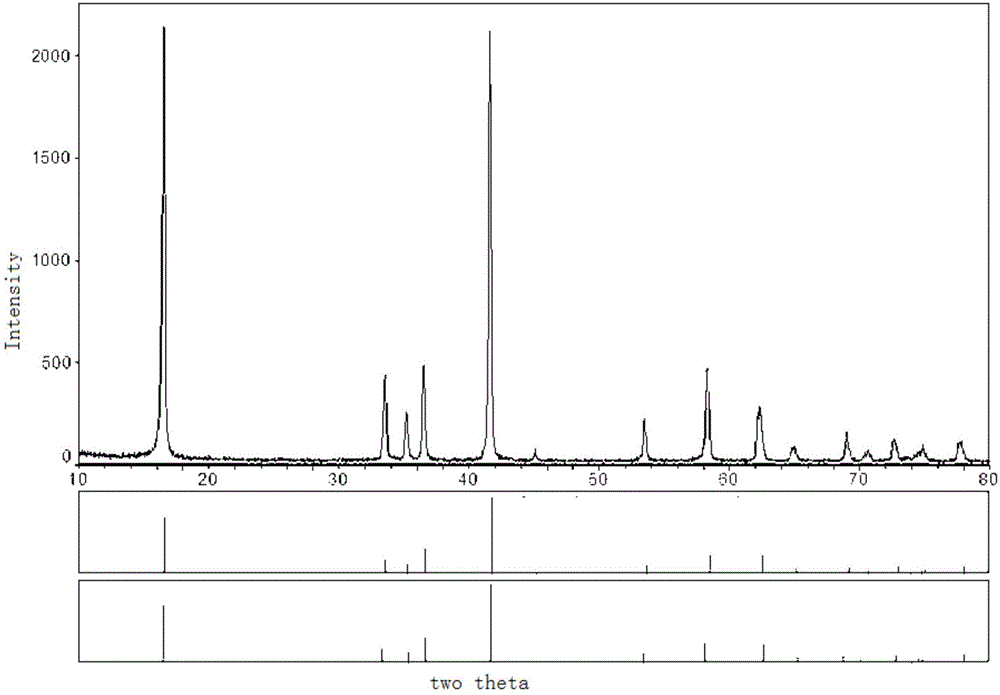

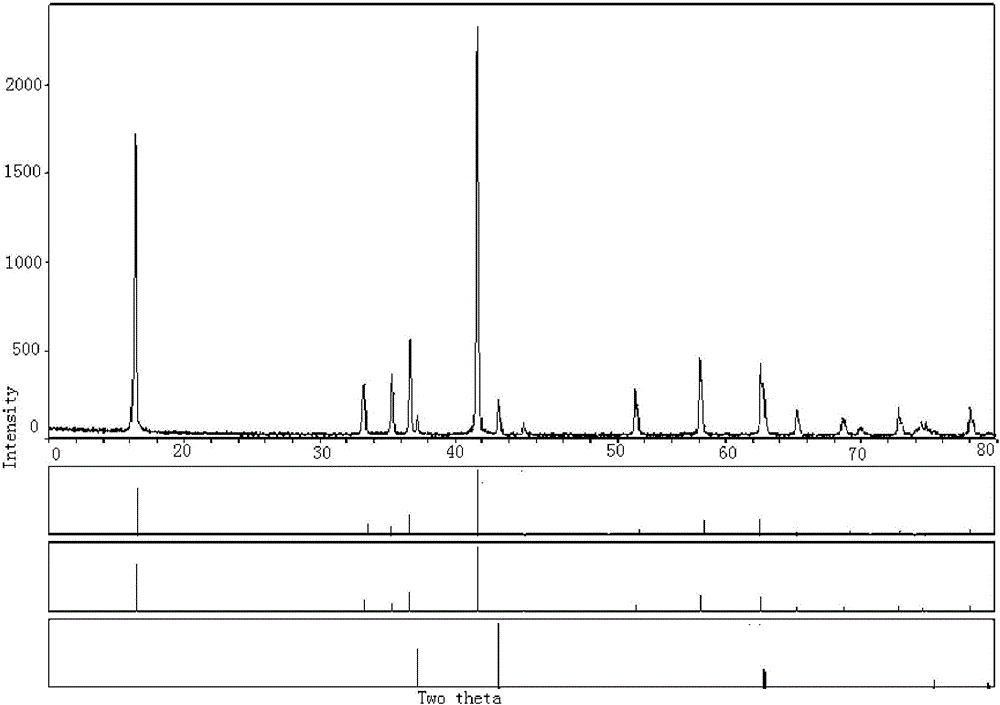

Image

Examples

Embodiment 1

[0033] This embodiment provides a Na(Ni 0.33 Fe 0.33 mn 0.33 )O 2 The preparation method of material comprises the following steps:

[0034] The first step, the preparation of nickel, iron, manganese solution: dissolve 8.17g manganese acetate, 8.29g nickel acetate, 5.06g ferrous sulfate in 250g deionized water, stir and dissolve evenly, obtain salt solution;

[0035] The second step, the preparation of the precursor gel: add dropwise 500 g of citric acid solution with a concentration of 0.1 g / mL to the salt solution prepared in the first step, react in a water bath at 40°C for 2 hours, adjust the pH to 5.5 with ammonia water, and The temperature was raised to 70°C and reacted for 8 hours to obtain a wet gel;

[0036] The third step, preparation of the positive electrode material: dry the wet gel obtained in the second step at 100°C for 10 hours, mix the dried product with 5.51g of sodium carbonate, ball mill for 2 hours, and then calcinate in air at 450°C for 4 hours, Tak...

Embodiment 2

[0040] This embodiment provides a Na(Ni 0.4 Fe 0.2 mn 0.4 )O 2 The preparation method of material comprises the following steps:

[0041] The first step, the preparation of nickel, iron, manganese solution: dissolve 11.15g manganese nitrate, 6.46g nickel nitrate, 6.75g ferrous sulfate in 250g deionized water, stir and dissolve evenly, obtain salt solution;

[0042] The second step, preparation of the precursor gel: 500 g of citric acid solution with a concentration of 0.3 g / mL was added dropwise to the salt solution prepared in the first step, and reacted in a water bath at 35° C. for 3.5 hours. Adjust the pH to 5.2 with ammonia water, raise the temperature of the water bath to 80°C, and react for 6 hours to obtain a wet gel;

[0043] The third step, preparation of positive electrode material: dry the wet gel obtained in the second step at 110°C for 10 hours, mix the dried product with 5.51g of sodium carbonate, ball mill for 2 hours, and then calcinate at 500°C in air for...

Embodiment 3

[0046] This embodiment provides a Na(Ni 0.2 Fe 0.5 mn 0.3 )O 2 The preparation method of material comprises the following steps:

[0047] The first step, the preparation of nickel, iron, manganese solution: dissolve 8.17g manganese acetate, 5.53g nickel acetate, 7.03g ferrous sulfate in 250g deionized water, stir and dissolve evenly, obtain salt solution;

[0048] The second step, preparation of the precursor gel: 500 g of citric acid solution with a concentration of 0.5 g / mL was added dropwise to the salt solution prepared in the first step, and reacted in a water bath at 45° C. for 2 hours. Adjust the pH to 6.0 with ammonia water, raise the temperature of the water bath to 70°C, and react for 15 hours to obtain a wet gel;

[0049] The third step, preparation of positive electrode material: dry the wet gel obtained in the second step at 90°C for 15 hours, mix the dried product with 5.51g of sodium carbonate, ball mill for 2 hours, and then calcinate at 450°C in air for 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com