A kind of conjugated porous polymer capacitive material and its preparation method and application

A technology of porous polymers and polymers, applied in the direction of hybrid capacitor electrodes, etc., to achieve the effects of simple preparation methods, high yields, and excellent redox reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of embodiment 1 trinitro-tri-carbazole

[0027] (1) Under nitrogen protection conditions, tricarbazole (593.5mg, 1.0mmol) was dissolved in 5mL of dichloromethane (CH 2 Cl 2 ), add 65% nitric acid (0.24mL, 5mmol), react at room temperature for 3 hours, after the reaction is completed, extract with dichloromethane, then dry with anhydrous magnesium sulfate, filter, distill off the solvent, and the solid obtained is separated and purified by column chromatography , to obtain a red powder (573mg), yield 78%.

[0028] (2) Under nitrogen protection conditions, tricarbazole (593.5mg, 1.0mmol) was dissolved in 6mL of dichloromethane (CH 2 Cl 2 ), add 65% nitric acid (0.25mL, 6mmol), and react at room temperature for 3 hours. After the reaction is completed, extract with dichloromethane, then dry with anhydrous magnesium sulfate, filter, distill off the solvent, and the solid obtained is separated and purified by column chromatography , to obtain a red powder...

Embodiment 2

[0032] (1) Under nitrogen protection, mix trinitrotricarbazole (650mg, 1.0mmol) and Pd / C (19mg, 1mmol) with 5mL of DMF, and slowly add N 2 h 4 ·H 2O (1.5mL, 30.0mmol), reacted for 8h. After the reaction was completed, it was cooled to room temperature, extracted with dichloromethane, then dried with anhydrous magnesium sulfate, filtered, and the solvent was evaporated to obtain a solid that was separated and purified by column chromatography to obtain a red powder (750 mg), with a yield of 73%.

[0033] (2) Under nitrogen protection, mix trinitrotricarbazole (650mg, 1.0mmol) and Pd / C (23mg, 1.2mmol) with 10mL of DMF, and slowly add N 2 h 4 ·H 2 O (1.2 mL, 24.0 mmol), reacted for 8 h. After the reaction was completed, it was cooled to room temperature, extracted with dichloromethane, then dried with anhydrous magnesium sulfate, filtered, and the solvent was evaporated to obtain a solid that was separated and purified by column chromatography to obtain a red powder (770 mg)...

Embodiment 3

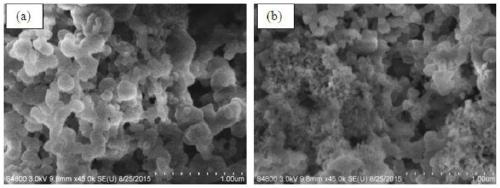

[0037] (1) Dissolve triaminotricarbazole (642mg, 1.0mmol) and pyromellitic dianhydride (327mg, 1.5mmol) in 1,4-dioxane and mesitylene at a volume ratio of 1:2 middle. The solution was cooled in liquid nitrogen for 5 minutes and evacuated, then the reaction bottle was sealed and reacted at 100°C for 2 days, the reaction product was extracted with anhydrous dichloromethane for 1 day, and the solvent was spin-dried to obtain the porous polymer TAT-CMP -1 (750 mg), yield 82%.

[0038] (2) Dissolve triaminotricarbazole (642mg, 1.0mmol) and pyromellitic dianhydride (327mg, 1.5mmol) in 1,4-dioxane and mesitylene at a volume ratio of 1:2 middle. The solution was cooled in liquid nitrogen for 6 minutes and evacuated, then the reaction bottle was sealed and reacted at 120°C for 2 days, the reaction product was extracted with anhydrous dichloromethane for 1 day, and the solvent was spin-dried to obtain the porous polymer TAT-CMP -1 (732 mg), 80% yield.

[0039] (3) Dissolve triaminot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com