Preparation method of amphetamine

A technology of amphetamine and phenylacetone, which is applied in the field of preparation of amphetamine, and can solve the problems of low purity of amphetamine and unreasonable process setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

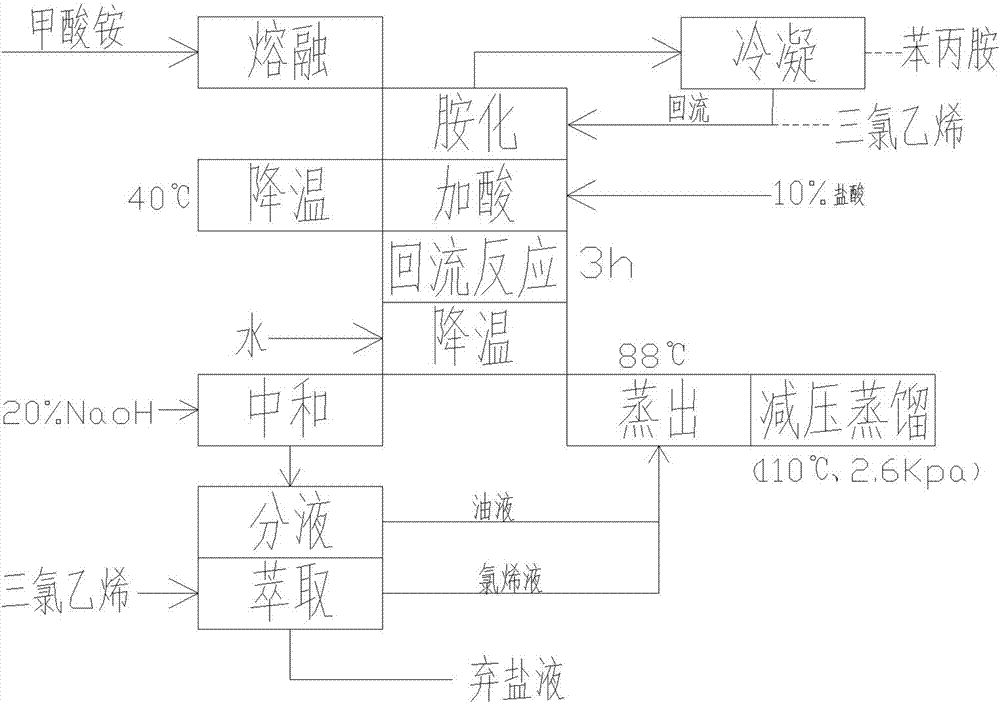

Method used

Image

Examples

Embodiment 1

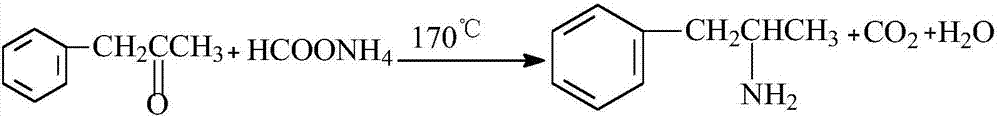

[0023] The preparation method of amphetamine, comprises the following steps:

[0024] a. Add ammonium formate into the enamel reaction kettle, and then feed hot oil at 150°C into the jacket of the enamel reaction kettle to make the ammonium formate a molten liquid;

[0025] b. Heat the ammonium formate melt to 173°C, then drop phenylacetone to form a mixed solution, the molar ratio between phenylacetone and ammonium formate is 1:1.2;

[0026] c. The ammonium formate and phenylacetone in the mixed solution were reacted at 170°C for 3.5 hours to obtain a reaction solution. During the reaction process of ammonium formate and phenylacetone, the evaporated substance was condensed and returned to the mixture through a plastic coil; then cooled The oil reduces the temperature of the reaction solution to 40°C;

[0027] d, adding concentration to the reaction solution after cooling is 10% hydrochloric acid to make the reaction solution neutral;

[0028] e. Heat the reaction solution ...

Embodiment 2

[0033] The preparation method of amphetamine, comprises the following steps:

[0034] a. Add ammonium formate into the enamel reaction kettle, and then feed hot oil at 130°C into the jacket of the enamel reaction kettle to make the ammonium formate a molten liquid;

[0035] b. Heat the ammonium formate melt to 175°C, then drop phenylacetone to form a mixed solution, the molar ratio between phenylacetone and ammonium formate is 1:1.2;

[0036] c. The ammonium formate and phenylacetone in the mixed solution reacted at 175°C for 3 hours to obtain a reaction solution. During the reaction process of ammonium formate and phenylacetone, the evaporated substance was condensed and returned to the mixture through a plastic coil; Make the temperature of reaction solution drop to 40 ℃;

[0037] d, adding concentration to the reaction solution after cooling is 10% hydrochloric acid to make the reaction solution neutral;

[0038] e. Heat the reaction solution after adding hydrochloric aci...

Embodiment 3

[0043] The preparation method of amphetamine, comprises the following steps:

[0044] a. Add ammonium formate to the enamel reaction kettle, and then feed hot oil at 140°C into the jacket of the enamel reaction kettle to make the ammonium formate a molten liquid;

[0045] b. Heat the ammonium formate melt to 170°C, then add phenylacetone dropwise to form a mixed solution, and the molar ratio between phenylacetone and ammonium formate is 1:1.2;

[0046] c. The ammonium formate and phenylacetone in the mixed solution were reacted at 173°C for 3.5 hours to obtain a reaction solution. During the reaction process of ammonium formate and phenylacetone, the evaporated material was condensed and returned to the mixture through a plastic coil; then cooled The oil reduces the temperature of the reaction solution to 40°C;

[0047] d, adding concentration to the reaction solution after cooling is 10% hydrochloric acid to make the reaction solution neutral;

[0048] e. Heat the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com