Synergetic metal recycling method for nickel and cobalt containing waste batteries and copper containing electronic waste

A technology of electronic waste and waste batteries, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of low wet leaching efficiency, accompanying waste liquid generation, secondary pollution, etc., and achieve large market promotion Prospect, high efficiency, low impurity content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

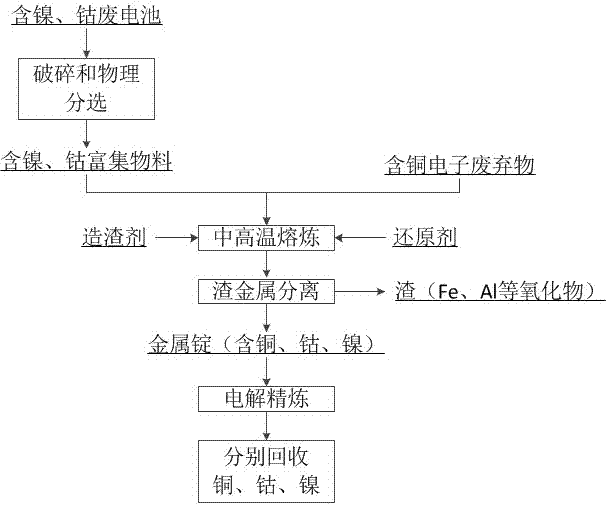

Method used

Image

Examples

Embodiment 1

[0043] The waste nickel-cobalt batteries were crushed into 5~15mm×5~15mm fragments, and gravity separation was carried out to obtain 1kg of nickel- and cobalt-enriched materials, which were mixed with 2kg of copper-containing electronic waste. Put the mixture into a graphite crucible and heat it to 1100°C in an induction furnace. After the temperature stabilizes, add 200g of calcium-aluminum-silicon slagging agent and 20g of activated carbon mixed agent, in which CaO:Al 2 o 3 : SiO 2The mass ratio is 40:30:30. The smelting time is 1 hour, supplemented by mechanical, gas or electromagnetic stirring to assist iron and aluminum elements to enter the slag phase and remove harmful impurities. After smelting, the crucible is cooled to room temperature, and metals containing copper, nickel, and cobalt are obtained by mechanical separation. The resulting metals are cut into thin slices and subjected to electrolytic refining to obtain high-purity copper, nickel, and cobalt metals re...

Embodiment 2

[0045] The nickel-cobalt-lithium-aluminate ternary lithium battery was broken into 5~15mm×5~15mm fragments, and gravity sorting was carried out to obtain 2kg of nickel and cobalt-enriched materials, which were mixed with 5kg of copper-containing electronic waste. Put the mixture into a graphite crucible and heat it to 1200°C in an induction furnace. After the temperature stabilizes, add 200g of calcium-aluminum-silicon slagging agent and 60g of activated carbon mixed agent, in which CaO: Al 2 o 3 : SiO 2 The mass ratio is 60: 25: 25. The smelting time is 1 hour, supplemented by mechanical, gas or electromagnetic stirring to increase iron and aluminum elements into the slag phase and remove harmful impurities. Remove slag at high temperature to obtain metals containing copper, nickel and cobalt. The resulting metals are cut into thin slices and subjected to electrolytic refining to obtain high-purity copper, nickel, and cobalt metals.

Embodiment 3

[0047] The nickel-cobalt lithium manganese oxide ternary lithium battery was broken into 5~15mm×5~15mm fragments, and gravity separation was carried out to obtain 2kg of nickel and cobalt-enriched materials, which were mixed with 2kg of copper-containing electronic waste. Put the mixture into a graphite crucible and heat it to 950°C in an induction furnace. After the temperature stabilizes, add 200g of calcium-aluminum-silicon slagging agent and 60g of activated carbon mixture, in which CaO:Al 2 o 3 : SiO 2 The mass ratio is 60: 20: 20. The smelting time is 1 hour, supplemented by mechanical stirring to increase iron and aluminum elements into the slag phase and remove harmful impurities. After smelting, the crucible is cooled to room temperature, and metals containing copper, nickel, and cobalt are obtained by mechanical separation. The resulting metals are cut into thin slices and subjected to electrolytic refining to obtain high-purity copper, nickel, and cobalt metals. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com