Metal melt purifying device

A metal melt and purification device technology, which is applied in chemical instruments and methods, improvement of process efficiency, separation methods, etc., can solve the problems of influence of metal melt purification effect, increase of settling time, incomplete settling, etc., so as to shorten settling time, improve the purification effect, improve the effect of the sedimentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

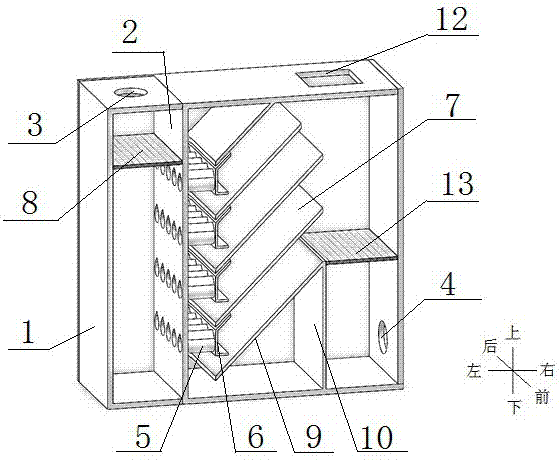

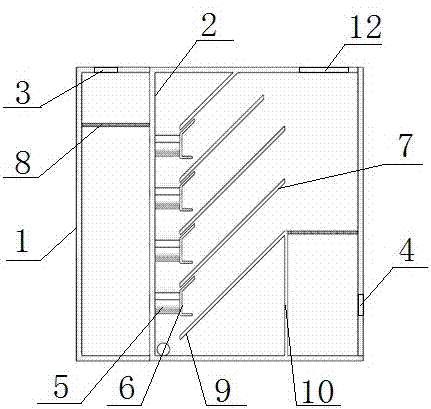

[0023] Embodiment one, see figure 1 and figure 2 , the single-stage purification device for molten metal shown includes a housing 1 and a partition 2, the partition 2 is placed vertically in the housing 1 and separates the housing 1 into a filter chamber and a settling chamber, the The clapboard 2 is provided with a plurality of collecting holes connecting the filter chamber and the settling chamber, the settling chamber is provided with a settling mechanism, the side wall of the settling chamber is provided with a metal melt inlet 3; the above filter chamber is provided with a metal melt The outlet 4 is provided with a first filter plate 8 in the filter chamber, and the first filter plate is fixed between the molten metal outlet 4 and the highest collecting hole. The top of the shell 1 is provided with an upper slag discharge port 12, which is located at the upper right of the settling mechanism, and the upper slag discharge port is used to scoop out floating inclusions wit...

Embodiment 2

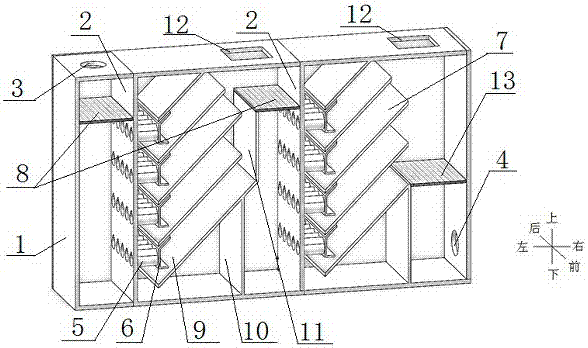

[0027] Embodiment two, see image 3 and Figure 4 , the shown two-stage purification device for molten metal, by analogy with the device in Embodiment 1, the first stage composed of the filter chamber, the settling chamber and the inclusion collection chamber is sequentially arranged in the housing 1 The purification part and the second-level purification part, the first filter plate 8 of the first-level purification part is fixedly connected with the lowermost inclined plate 9 of the second-level purification part through a connecting plate 11, ensuring that the The metal melt in the drainage pipe 5 is all filtered by the first filter plate 8 of the first-stage purification part, and then enters the second-stage purification part. Through multiple sedimentation and filtration, the purification effect of the metal melt is further improved.

[0028]During specific work, the metal melt enters the housing 1 from the metal melt inlet 3, and then enters the second-stage purificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com