Mortar coating machine for uniformly coating mortar on vertical surfaces and upper surfaces of bricks and mortar coating method

A vertical surface, sizing machine technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of inconvenient use and poor automation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

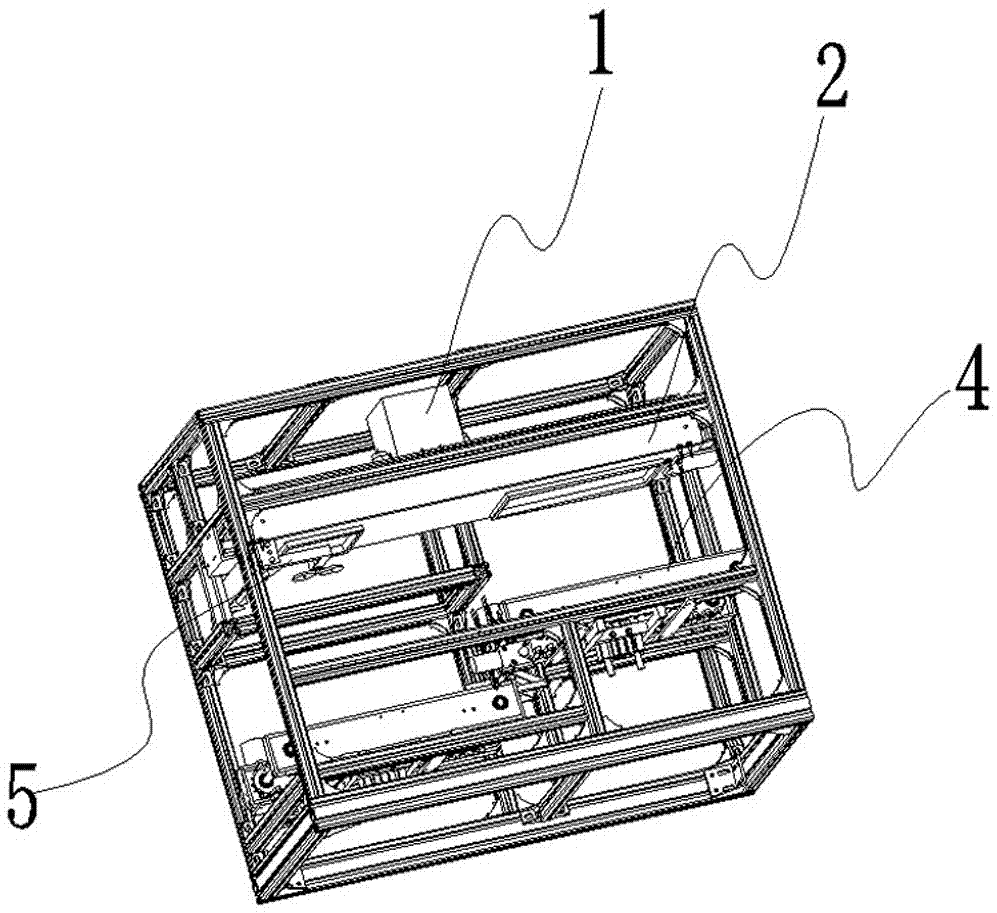

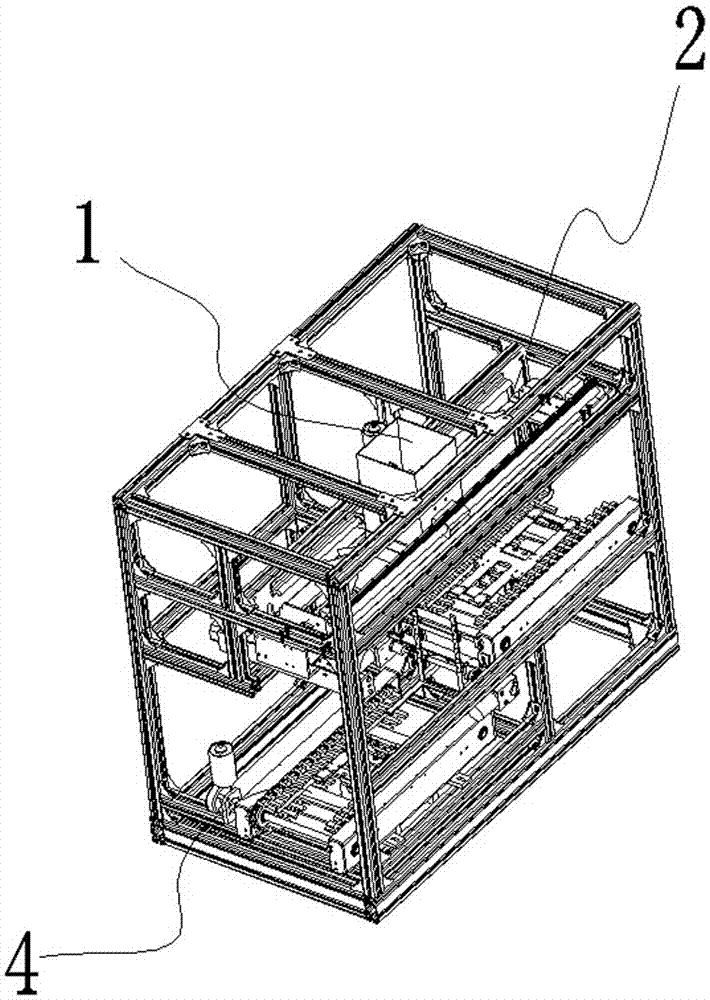

[0052] like Figure 1-2 As shown, the sizing machine for evenly applying mortar on the vertical surface and upper surface of bricks according to the present invention includes an automatic sizing mechanism, a net hanging mechanism 5 and a conveying mechanism 4. Mortar chamber 1 and supporting plate 2;

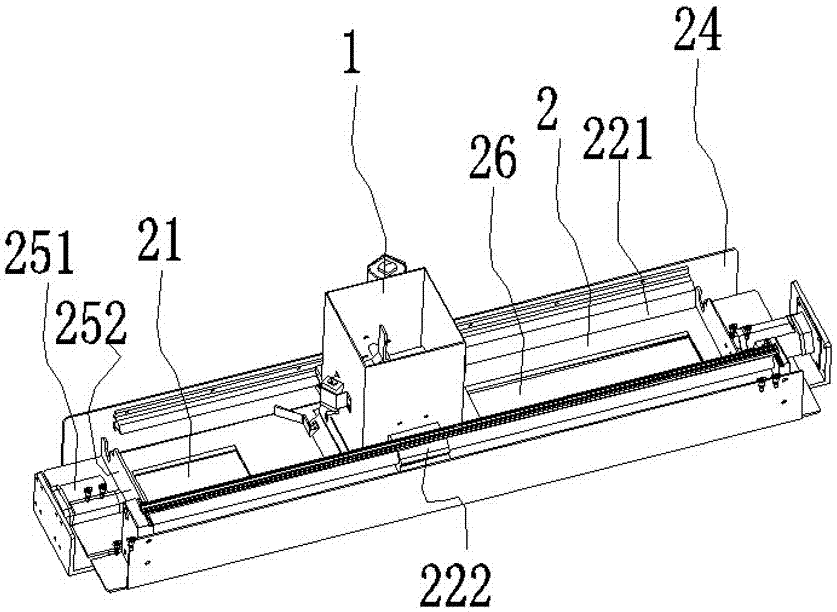

[0053] Among them, such as Figure 3-7 As shown, the mortar containing cavity 1 in the automatic sizing mechanism is arranged on the supporting plate 2, and the supporting plate 2 is provided with a first mortar discharge port 21 and a second mortar discharge port 26, and also includes a transmission mechanism 22. The mortar accommodating cavity 1 reciprocates on the supporting plate 2 through the transmission mechanism 22; the first mortar feeding port 21 on the back of the supporting plate 2 is protruding downward around the first mortar for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com