Rock burst control method in deep mining area of coal mine

A technology of rock burst and mining areas, which is applied in ground mining, earth drilling, underground mining, etc., and can solve the problems of poor prevention and control of rock burst disasters and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

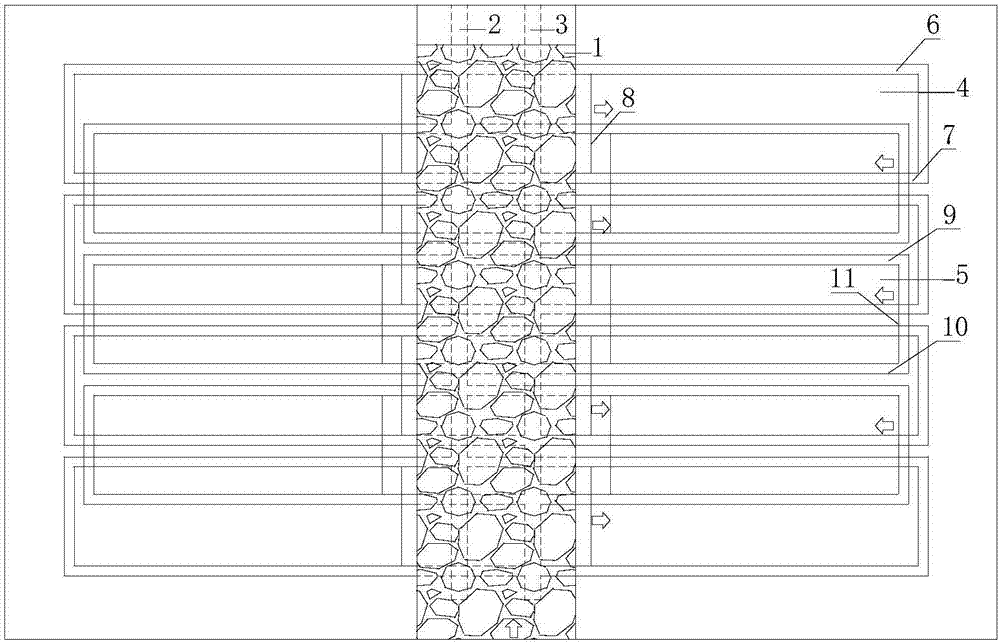

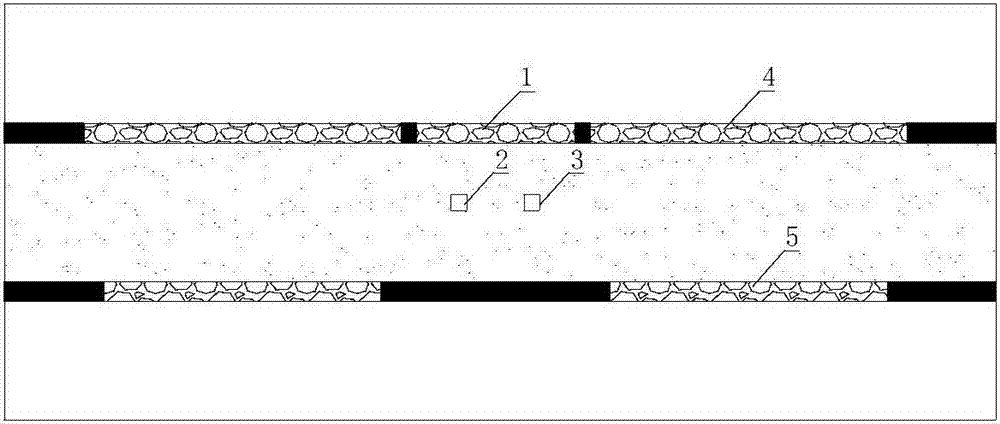

[0033] The embodiment of the present application provides a method for preventing and controlling rock burst in the deep mining area of a coal mine to solve the problem of poor prevention and control of rock burst disasters in the coal pillar area of the upper and lower hills (big alleys) in the coal seam group double-wing joint arrangement in the prior art, and consumes a lot of money. technical problems; the technical effect of improving the local control effect and reducing the cost has been achieved.

[0034] In order to better understand the above technical solutions, the above technical solutions will be described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the embodiments of the present invention and the specific features in the embodiments are detailed descriptions of the technical solutions of the present application. , rather than limiting the technical solutions of the present app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com