Pipe shaft

A pipeline well and pipe body technology, applied in vertical pipelines, pipes, branch pipelines, etc., can solve the problems of pipe material detachment, road subsidence, loose foundation, etc. Reduce the effect of loose foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

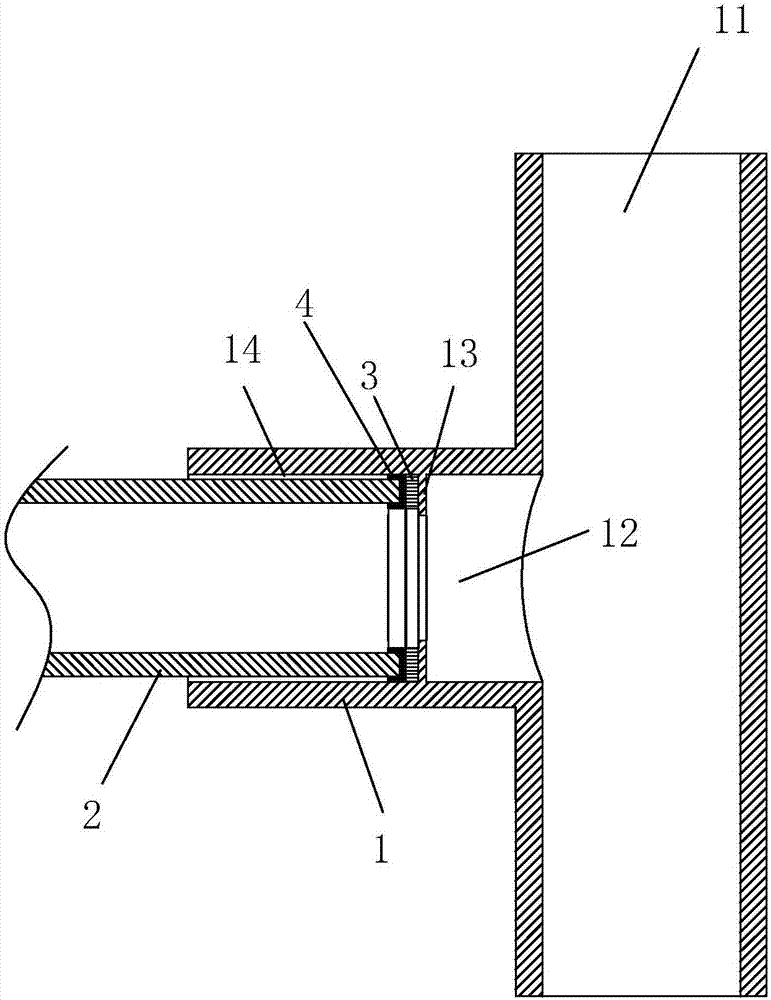

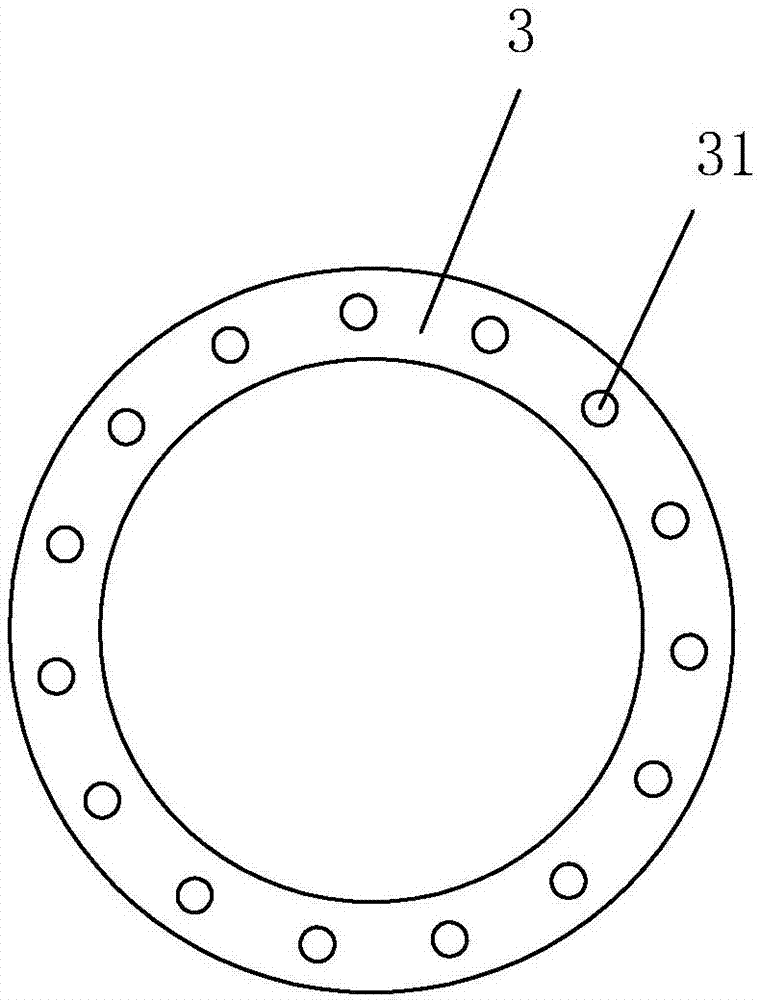

[0044] Embodiment one: a kind of pipeline well, see figure 1 , including a pipe body 1, the pipe body 1 includes an inlet 11 and an outlet 12, when installed, generally the inlet 11 is vertically upward, and the outlet 12 is horizontally oriented. The inner wall of the outlet 12 is provided with an internal thread 14, and the inner wall of the pipe body 1 inside the thread 14 is provided with an annular retaining ring 13, and the retaining ring 13 is integrally formed by protruding inward from the inner wall of the pipe body 1. A rigid ring pad 3 is arranged on the outer side of the retaining ring 13, and the rigid ring pad 3 can be made of hard metals such as iron, copper, stainless steel, or hard plastics such as ABS, POM, PS, PMMA, PC, PET, PBT, and PPO. become. A sealing ring 4 is placed on the outer side of the rigid ring gasket 3, and the cross section of the sealing ring 4 is U-shaped.

[0045] The end of the pipe 2 is provided with an external thread 14 that cooperat...

Embodiment 2

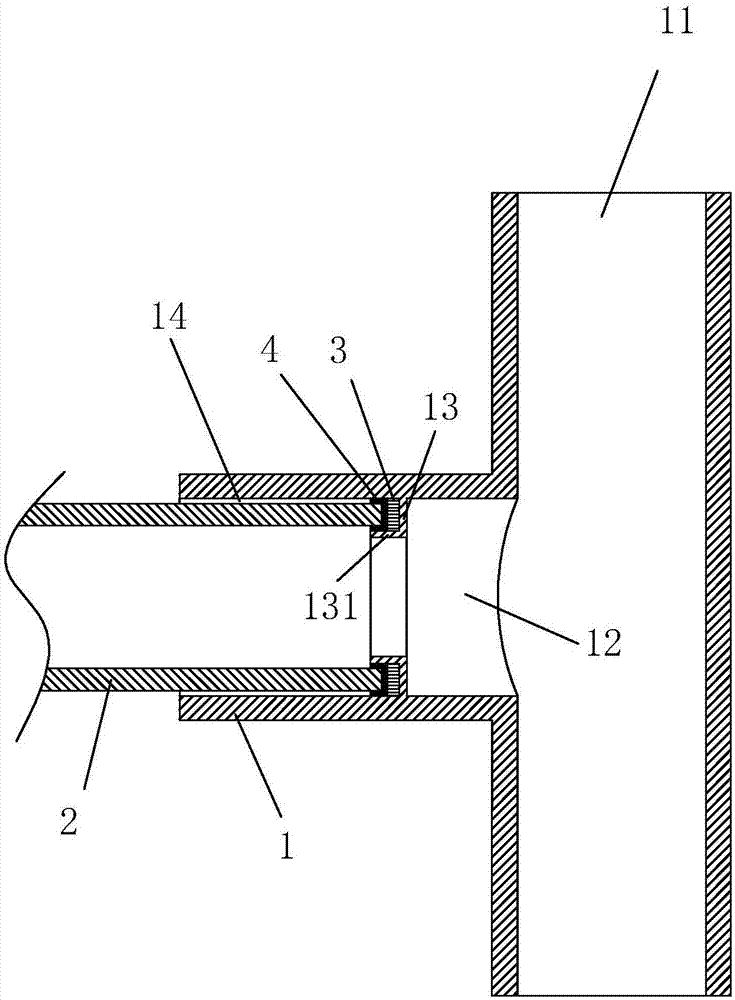

[0047] Embodiment two: a kind of pipeline well, see image 3 The difference between this embodiment and Embodiment 1 is that the inner side of the retaining ring 13 protrudes outward to form a flange 131, and the rigid ring gasket 3 and the sealing ring 4 are placed on the inner wall of the pipe body 1, the retaining ring 13 and the flange 131. within the enclosed space.

Embodiment 3

[0048] Embodiment three: a kind of pipeline well, see Figure 4 The difference between this embodiment and Embodiment 1 is that the internal thread 14 at the outlet 12 is eliminated, the external thread 14 is provided on the outer wall of the outlet 12, and the stop ring 13 is arranged on the outer wall of the pipe body 1 inside the external thread 14.

[0049] At this time, the end of the pipe material 2 is provided with an internal thread 14, and the pipe material 2 is matched with the pipe well to connect the two with the thread 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com