Afterheat recycling device for bottom slag of circulating fluidized bed boiler

A technology of circulating fluidized bed and recovery device, which is applied to fluidized bed combustion equipment, lighting and heating equipment, and burning fuel in a molten state, etc., can solve problems such as reducing energy quality, limiting waste heat recovery and utilization efficiency, etc. The effect of using convenience and prolonging contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

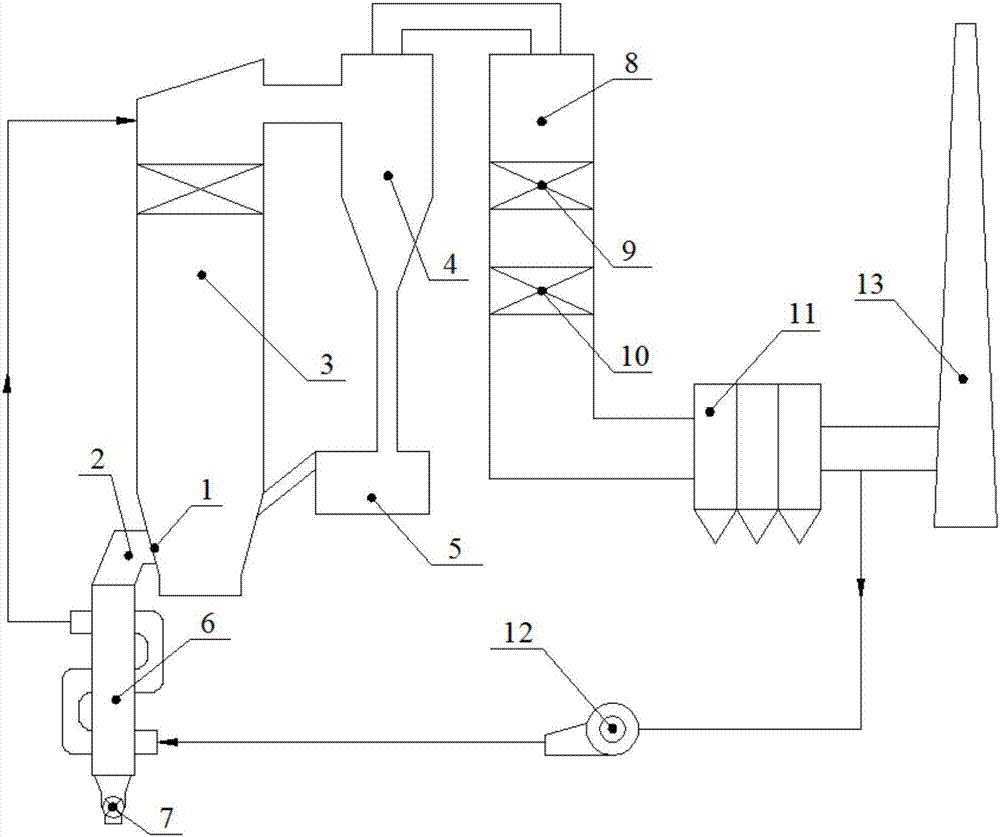

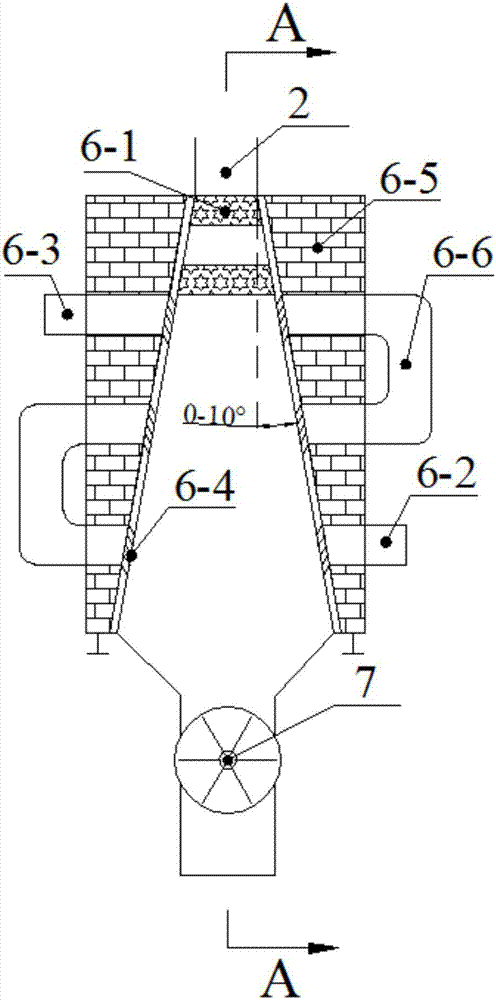

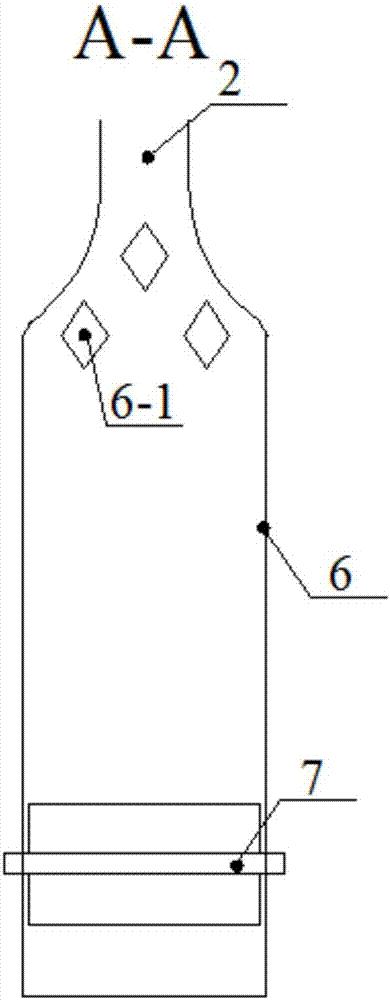

[0021] The structure of this embodiment is as figure 1 , figure 2 and image 3 As shown, this embodiment includes a slag inlet pipe 2, a moving bed heat exchanger 6 and a rotary slag discharge valve 7, and is characterized in that the moving bed heat exchanger 6 is composed of a bottom slag flow equalizing device 6-1, a cooling flue inlet 6 -2. Composed of cooling flue outlet 6-3, deflector 6-4, furnace wall 6-5 and cooling flue 6-6, the upper part of the moving bed heat exchanger 6 is provided with a slag inlet connected to the furnace 3 Tube 2, in the bottom slag channel of the moving bed heat exchanger 6, two of the opposite wall surfaces adopt a streamlined gradual expansion structure, and the gradual expansion angle of the other two opposite wall surfaces is 0-10°. A prismatic or streamlined cross-section bottom slag equalization device 6-1 made of high-temperature refractory castables is installed at the bottom slag inlet on the top of the device, and at the flue gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com