Rotating piston engine with compressing working independent chamber

A rotary engine, annular cavity technology, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve the problems of complex engine mechanism, reduced weight and size of the whole machine, and reduced charging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0092] The engine shaft completes N per revolution2 Secondary air intake (N is the number of protruding pistons of the compression disk or work disk), compression, combustion work, exhaust cycle, each cycle is the same. The following is an example of an engine with two protruding pistons per disk.

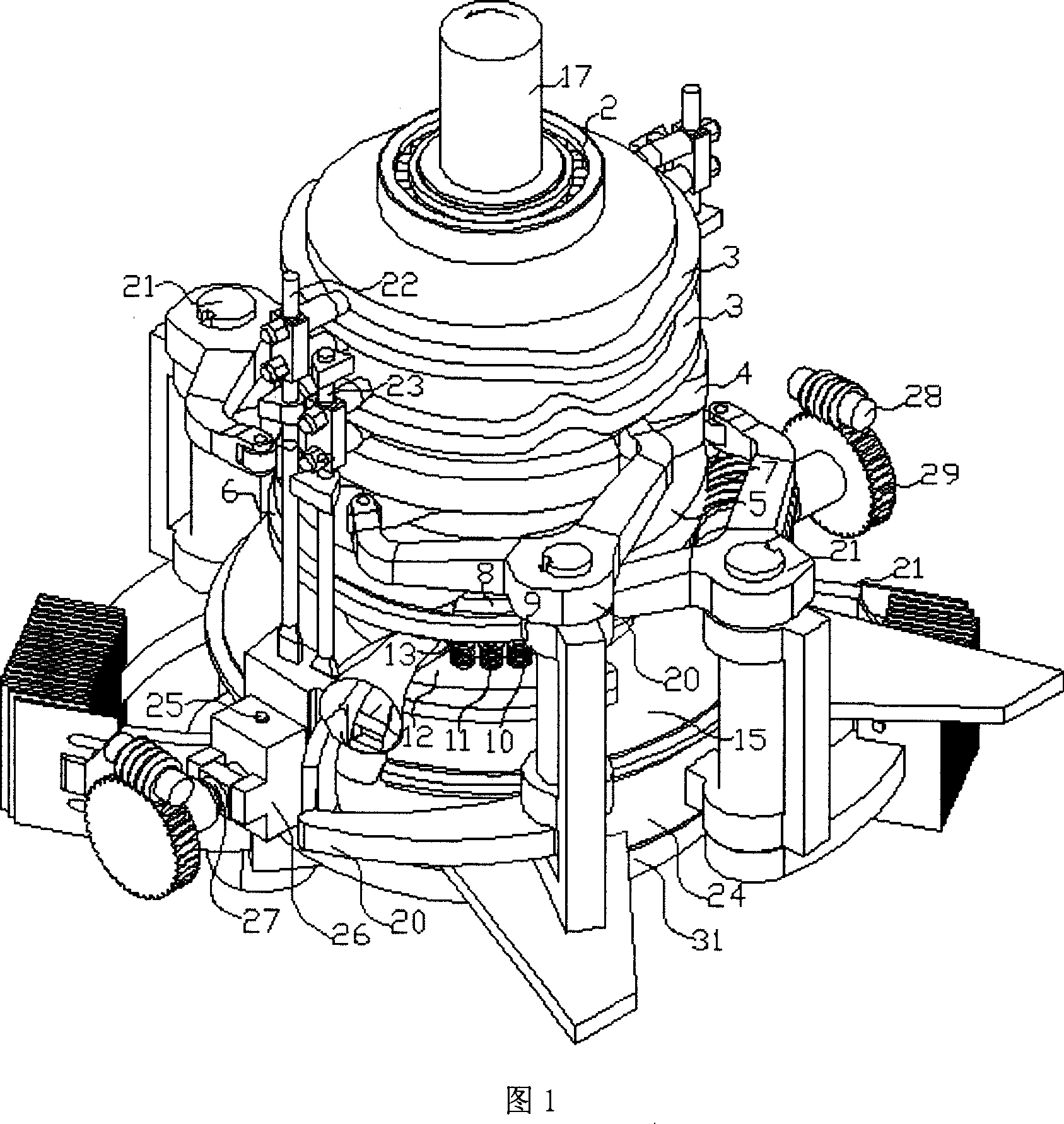

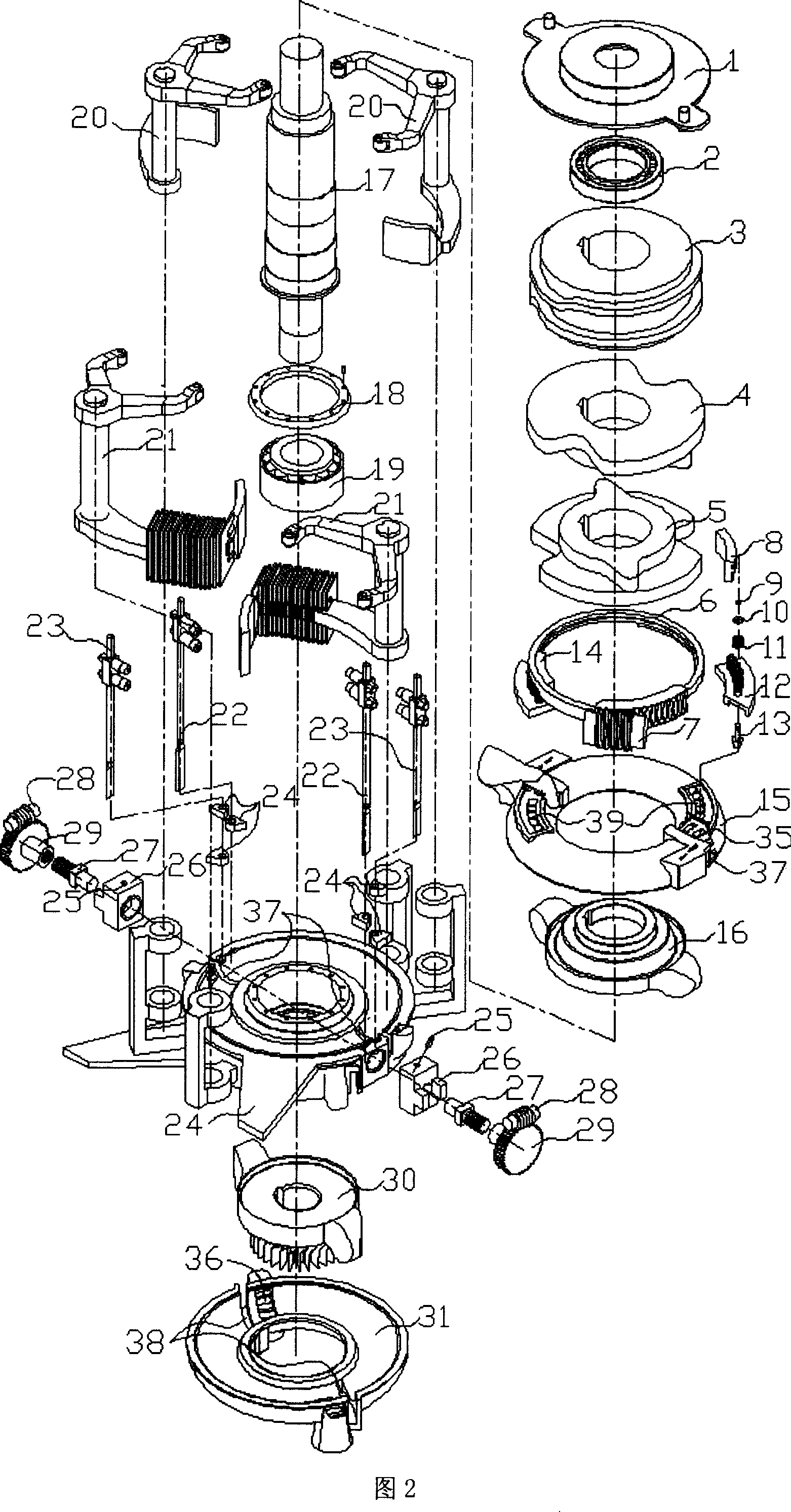

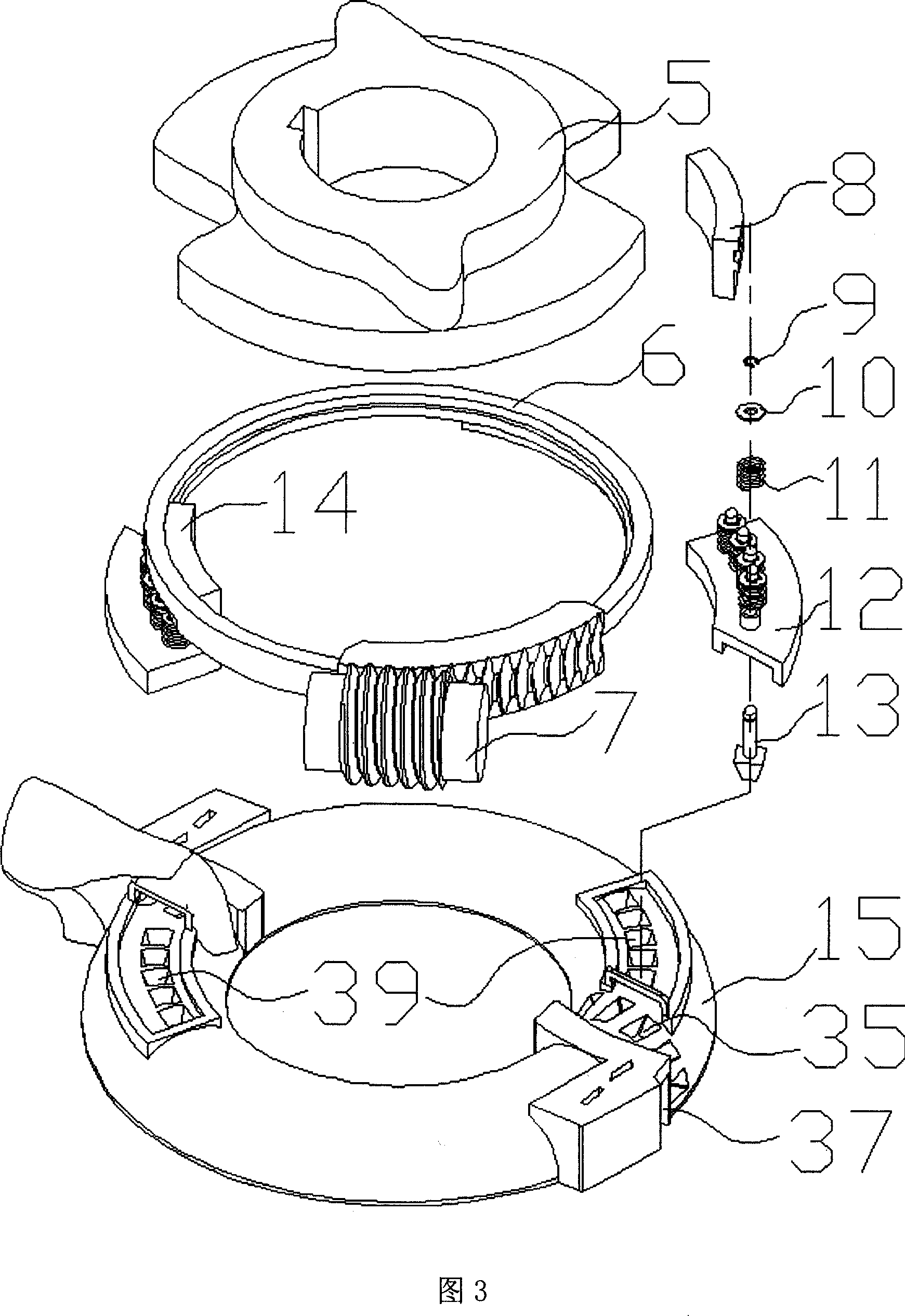

[0093] As shown in Figures 1 to 5:

[0094] 1. The main shaft (17) is fixed with the compression valve and the work valve drive cam (3), the compression ring slider drive cam (4), the work ring slider drive cam (5), the compression disc (16), the work disc (30 ), the main shaft is supported by the bearing (2) and the double-row tapered roller bearing (19), which bears the radial and axial loads of the main shaft, and the middle ring (24) and the bearing pressure plate (18) fix the double-row tapered roller bearing, Bearing (2) is fixed on the end cover (1).

[0095] 2. The C-shaped annular cavity formed by the compression half ring (15) and the middle ring (24) has an opening tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com