Method for overall calibration of galvanometer type line laser scanning three-dimensional measuring system

A technology of three-dimensional measurement and calibration method, which is applied in the field of optical three-dimensional scanning system calibration to achieve the effect of flexible calibration scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

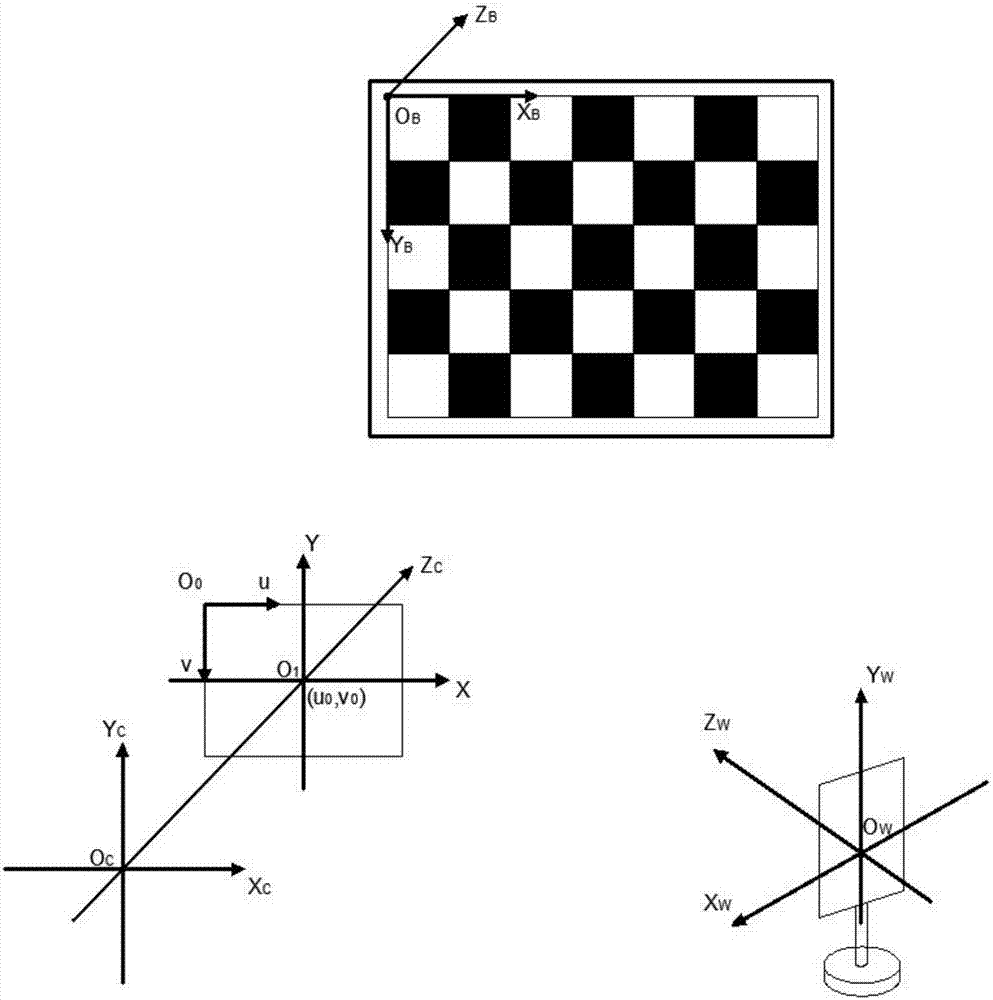

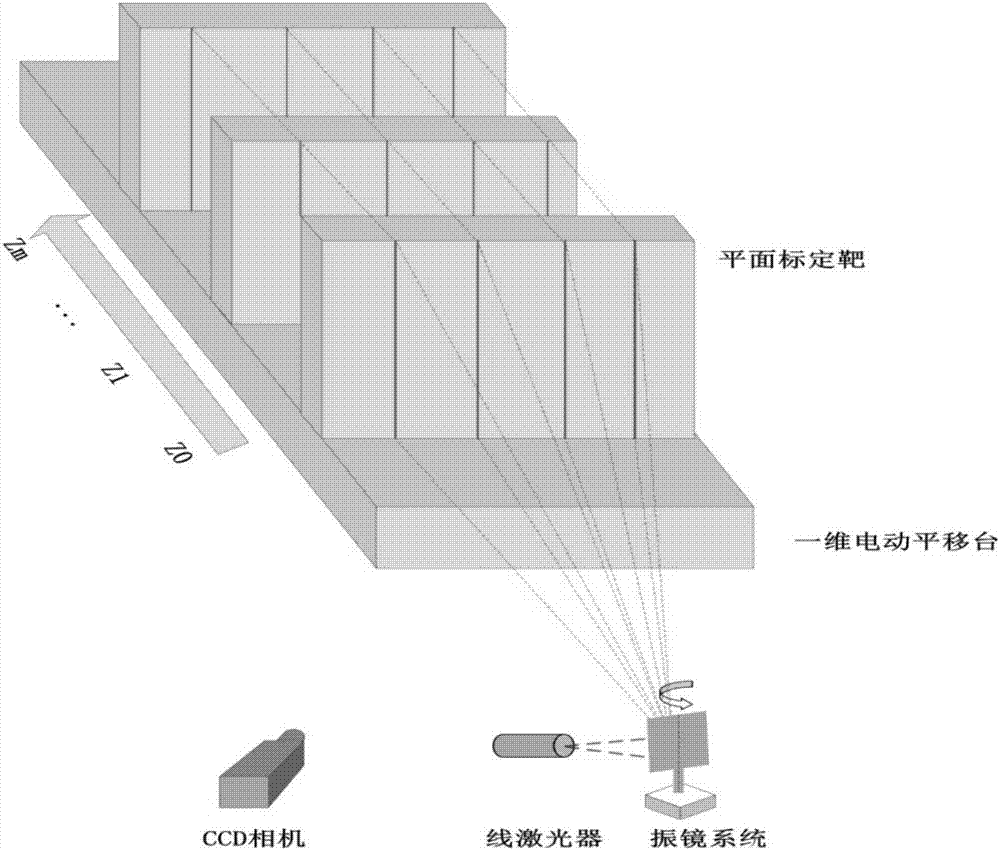

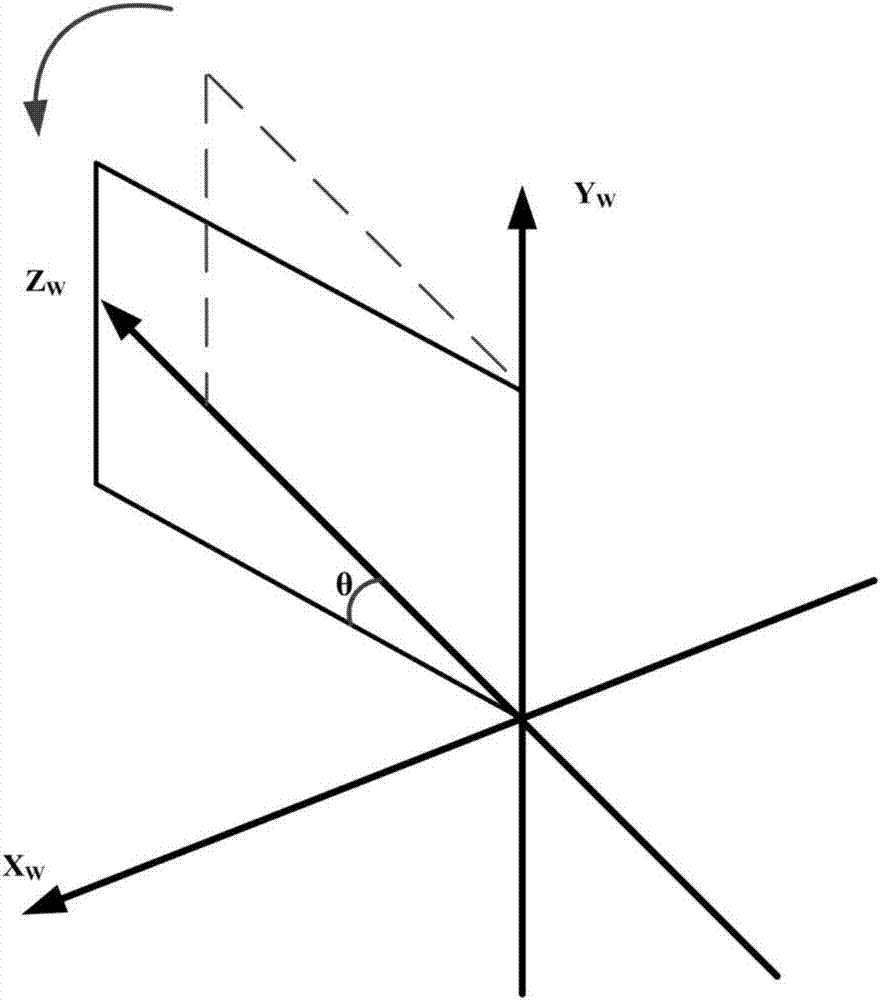

[0041] The galvanometer-type line laser scanning three-dimensional measurement system uses a galvanometer to replace the traditional mechanical scanning platform, and changes the rotation angle of the galvanometer through an external input control voltage, so that the reflected light of the line laser is aligned with the measured object along the direction of the galvanometer rotation. Optical measurement system for scanning surfaces. The extremely high repeatability and extremely small resolution of the galvanometer system make the measurement system expected to have extremely high measurement accuracy, and the level of calibration accuracy determines the level of the final measurement system of the system. The present invention divides the overal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com