High pressure water resistance

A high-pressure water and resistance technology, used in liquid resistors, resistance terminals/electrodes, power supply testing, etc., can solve the problems of a large number of resistance wires, a large area of cooling system equipment, and high construction costs, to eliminate the impact between the plates. Wear, solve large power fluctuations, and improve the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

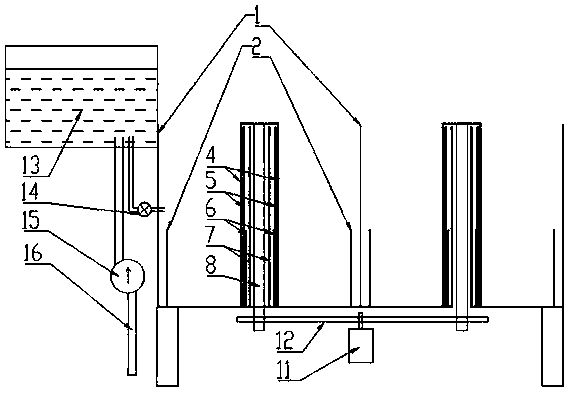

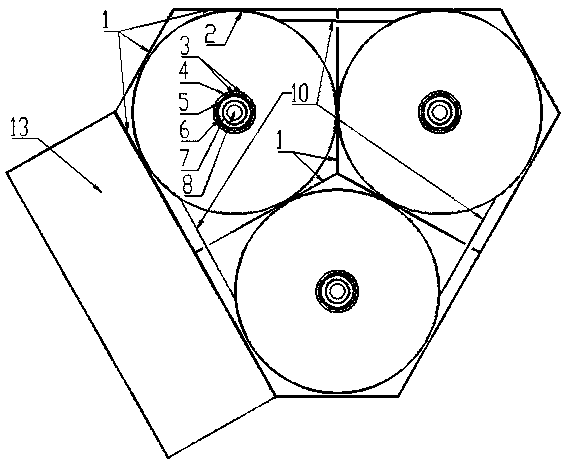

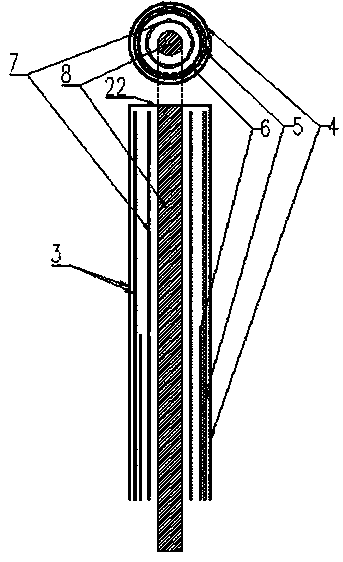

[0032] The present invention and its effects will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] Such as Figure 1-3 As shown, a high-pressure water resistor includes a working water tank 1 , a phase potential plate (positive plate) 6 , a zero potential plate (negative plate) 2 and a resistance adjustment mechanism 3 . The phase potential plate 6 and the zero potential plate 2 are hollow cylindrical structures with open upper ends, and a resistance adjustment mechanism 3 is set between the two plates, and the phase potential plate 6, the zero potential plate 2 and the resistance adjustment mechanism 3 are concentric Set in the working water tank 1; the resistance value adjustment mechanism 3 is provided with a water flow window connecting the phase potential plate 6 and the zero potential plate 2, and the resistance value adjustment mechanism 3 can adjust the size of the water flow window through relative displacement, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com