Ultraclean electric dust removing method and device

An electrostatic precipitator and dust technology, applied in the direction of electrode structure, electrostatic separation, external electrostatic separator, etc., can solve the problems of low dust removal efficiency with high specific resistance and difficulty in cleaning dust by electrostatic precipitator, so as to avoid secondary dust and solve the Difficulty cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

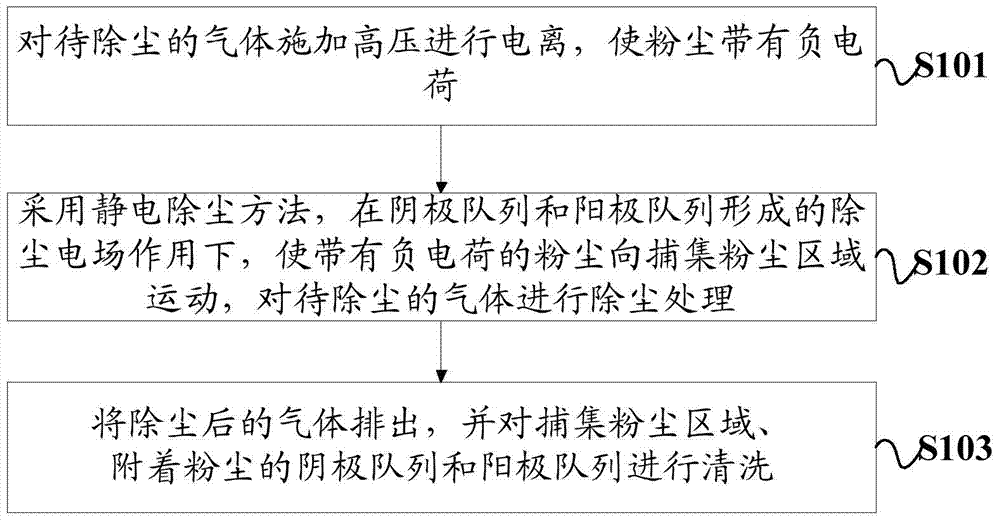

[0082] Such as figure 1 As shown, the embodiments of the present invention provide a method for ultra-clean electric dust removal, specifically comprising the following steps:

[0083] Step S101: Applying high pressure to the gas to be dedusted for ionization, so that the dust is negatively charged.

[0084] Dust-containing gas is electrically separated when it passes through a high-voltage electrostatic field, and the dust is combined with negative ions to be negatively charged.

[0085] Step S102: Using the electrostatic dust removal method, under the action of the dust removal electric field formed by the cathode queue and the anode queue, the negatively charged dust is moved to the dust collection area, and the gas to be dust removed is subjected to dust removal treatment.

[0086] Electrostatic dust removal is a kind of gas dust removal method. The dust-containing gas is electrically separated when it passes through a high-voltage electrostatic field. After the dust part...

no. 2 example

[0090] Based on the ultra-clean electrostatic precipitator method mentioned in the first embodiment above, this embodiment further describes the corresponding device.

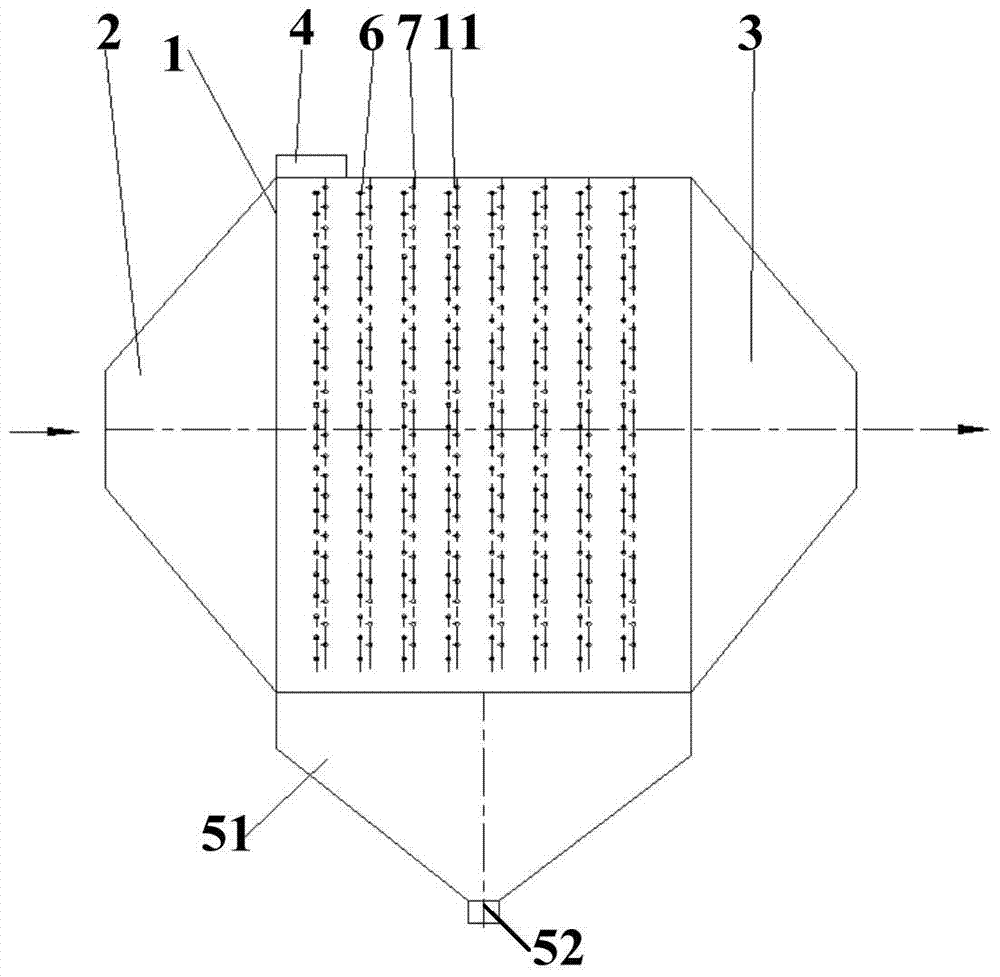

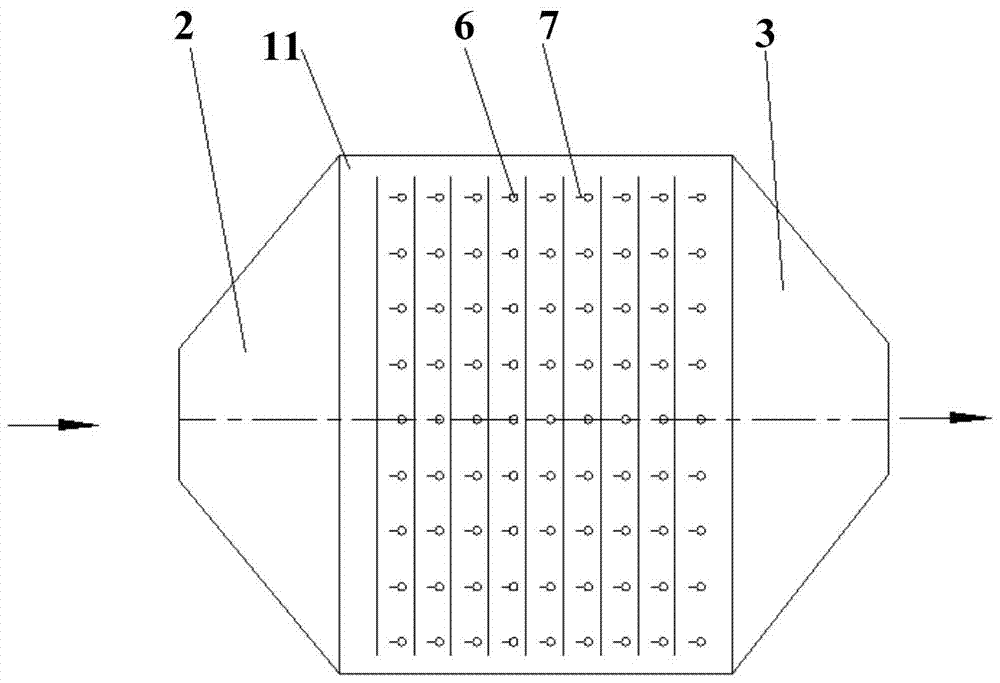

[0091] Specifically, such as Figure 2 to Figure 17 As shown, the ultra-clean electrostatic precipitator includes: device body 1, gas inlet 2, gas outlet 3, high-voltage power supply device 4, ash hopper 5, cathode queue 6, anode queue 7 and ash cleaning device 8.

[0092] Wherein, the device body 1 is provided with a dedusting chamber 11, and the gas to be dedusted is dedusted in the dedusting chamber 11. The gas inlet 2 is arranged on one side of the device body 1, the gas inlet 2 is connected with the dust removal chamber 11, and the high-voltage power supply device 4 is arranged on the side of the gas inlet 2, which is used to carry out the dedusting gas flowing through the gas inlet 2 into the dust removal chamber 11. Ionization, making the dust negatively charged. The gas outlet 3 is arranged on the sid...

no. 3 example

[0099] The following embodiment will further introduce the ultra-clean electrostatic precipitator of the present invention in conjunction with the accompanying drawings and specific structural implementations.

[0100] Specifically, such as Figure 2 to Figure 4 As shown, the ultra-clean electrostatic precipitator includes: device body 1, gas inlet 2, gas outlet 3, high-voltage power supply device 4, ash hopper 5, cathode queue 6, anode queue 7 and ash cleaning device 8. The above-mentioned ash hopper 5 includes: an accommodating chamber 51 and a plurality of baffles 53 disposed in the accommodating chamber 51 . Wherein, the accommodation chamber 51 is used to accommodate the collected dust. The accommodation chamber 51 is funnel-shaped. The bucket mouth 52, the bucket mouth 52 can pour out the dust accumulated in the accommodating chamber 51. The baffle 53 is arranged perpendicular to the airflow direction, and the size of the baffle 53 is set along with the cavity 51 , tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com