Lignin phenolic resin dust suppressant and preparation method thereof

A phenolic resin, lignin technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of difficulty in forming a dense dense layer, poor water retention performance, etc., achieving good economic and environmental benefits, uniform spraying, Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Add the first batch of formaldehyde solution 32g and the first batch of urea 13.3g into the glass reaction kettle equipped with agitator and condenser, use 8% sodium hydroxide solution to adjust the pH of the reaction solution to 8.0, raise the temperature After reaching 70°C, react for 1 h to carry out the first step reaction. After the reaction is over, keep the temperature, and add a sodium hydroxide solution with a concentration of 8% to adjust the pH of the reaction system to 11. After the adjustment, add 13.3g of lignin during the stirring process, stir continuously to dissolve it completely, and then add The remaining 48g of formaldehyde solution and 26.6g of phenol continued to react for 0.8h to carry out the second step reaction. Finally, after lowering the temperature to 65°C, the remaining 6.7g of urea was added again, and the reaction was carried out at this temperature for 0.5h. After finishing the reaction, cool and discharge to obtain a dark brown emulsi...

Embodiment 2

[0054] Add the first batch of formaldehyde solution 24g and the first batch of urea 13.3g into the glass reaction kettle equipped with agitator and condenser, use 8% sodium hydroxide solution to adjust the pH of the reaction solution to 8.0, raise the temperature After reaching 80°C, react for 0.8h to carry out the first step reaction. After the reaction is over, keep the temperature, and add a sodium hydroxide solution with a concentration of 8% to adjust the pH of the reaction system to 10.5. After the adjustment, add 10.64g of lignin during the stirring process, stir continuously to dissolve it completely, and then add The remaining 36g of formaldehyde solution and 26.6g of phenol continued to react for 0.5h to carry out the second step reaction. Finally, after lowering the temperature to 55° C., the remaining 6.7 g of urea was added again, and the reaction was carried out at this temperature for 1.0 h. After finishing the reaction, cool and discharge to obtain a dark brow...

Embodiment 3

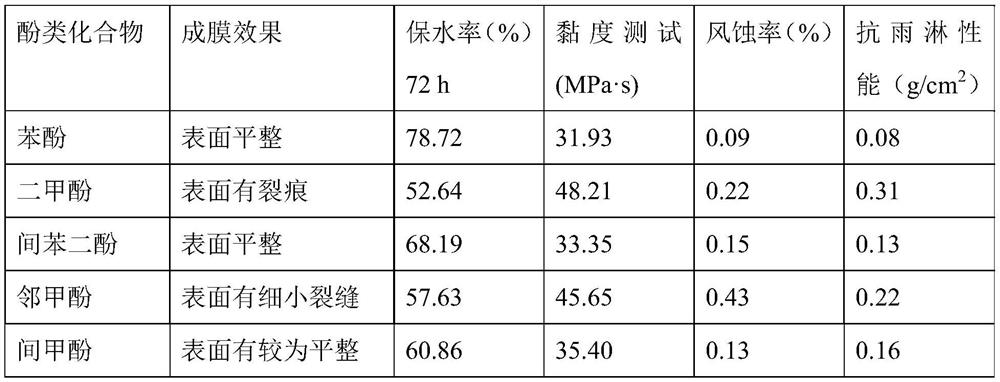

[0056] Add the first batch of formaldehyde solution 40g and the first batch of urea 13.3g into the glass reaction kettle equipped with agitator and condenser, use 8% sodium hydroxide solution to adjust the pH of the reaction solution to 8.0, raise the temperature After reaching 75°C, react for 0.5h to carry out the first step of reaction. After the reaction is over, keep the temperature, and add a sodium hydroxide solution with a concentration of 8% to adjust the pH of the reaction system to 11. After the adjustment, add 13.3g of lignin during the stirring process, stir continuously to dissolve it completely, and then add The remaining formaldehyde solution 60g and 39.9g xylenol continued to react for 0.8h to carry out the second step reaction. Finally, after lowering the temperature to 60°C, the remaining 6.7g of urea was added again, and the reaction was carried out at this temperature for 1.5h. After the reaction is finished, cool and discharge to obtain a dark brown emuls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com