Novel grain clearing equipment

A technology for cleaning grains and equipment, which is applied in the directions of drying and preserving seeds, separating solids, and separating solids from solids by air flow. , to achieve the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

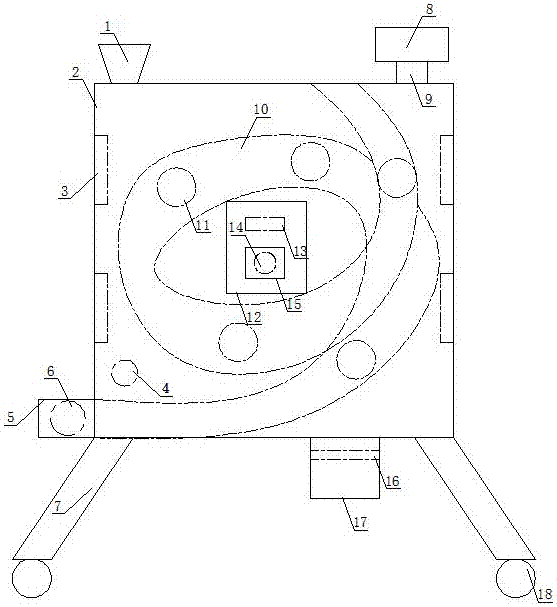

[0016] Such as figure 1 The new type of grain cleaning equipment includes a feed inlet 1, a body 2, an electric heater 3, a moisture sensor 4, a blower 5, an air volume controller 6, a bracket 7, a vacuum cleaner 8, a dust suction pipe 9, a spiral Pipeline 10, nozzle 11, main control panel 12, main controller 13, primary signal sensor 14, operation key 15, filter screen 16, discharge port 17, universal pulley 18, feed port 1 is set on the upper end of body 2 , a discharge port 17 is set at the lower end of the body 2, a support 7 is set at the lower ends of both sides of the body 2, a spiral pipe 10 is arranged in the body 2, several nozzles 11 are arranged on the spiral pipe 10, and blowing nozzles are arranged on the outer side of the body 2 Machine 5, blowing machine 5 is connected with spiral duct 10, and air volume controller 6 is set in blowing machine 5; The control panel 12 is provided with a main controller 13 inside the main control panel 12 . The wind blown in by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com