Semi-automatic vehicle roof DVD assembling device

An assembly device, semi-automatic technology, applied in the direction of motor vehicles, transportation and packaging, which can solve the problems of complex hovering control, few hovering points, and inability to accommodate vehicle positioning errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

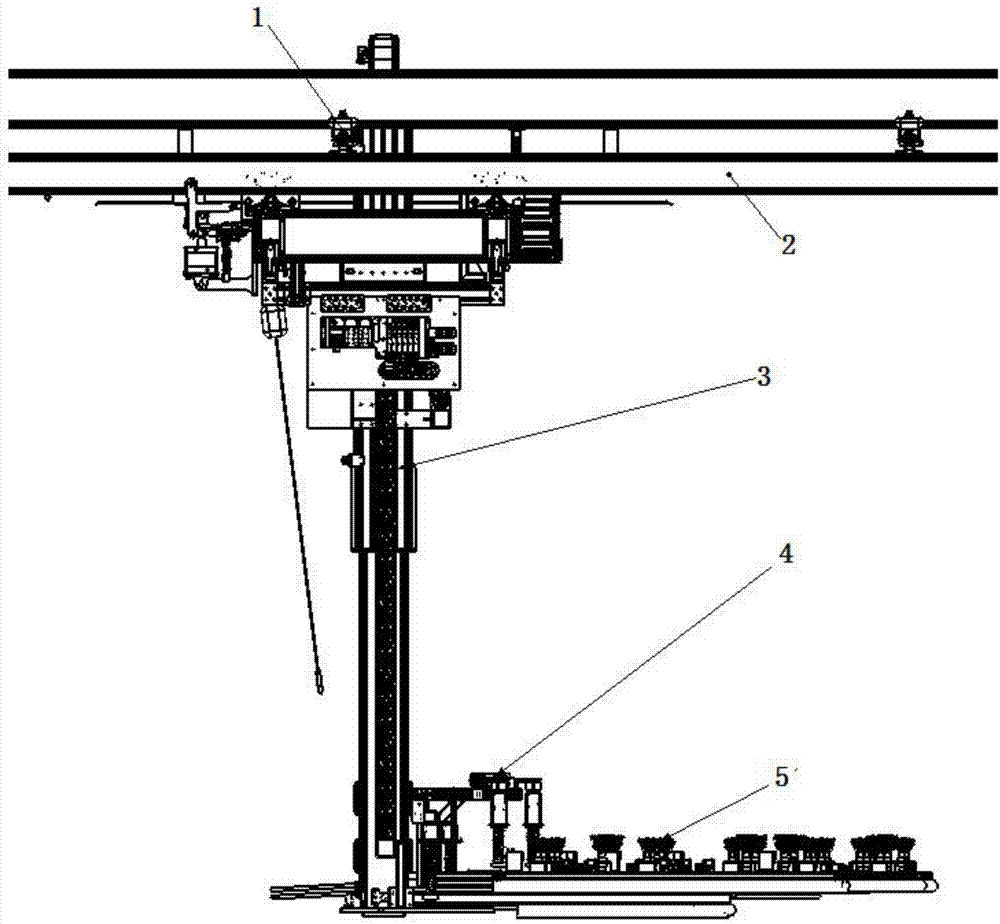

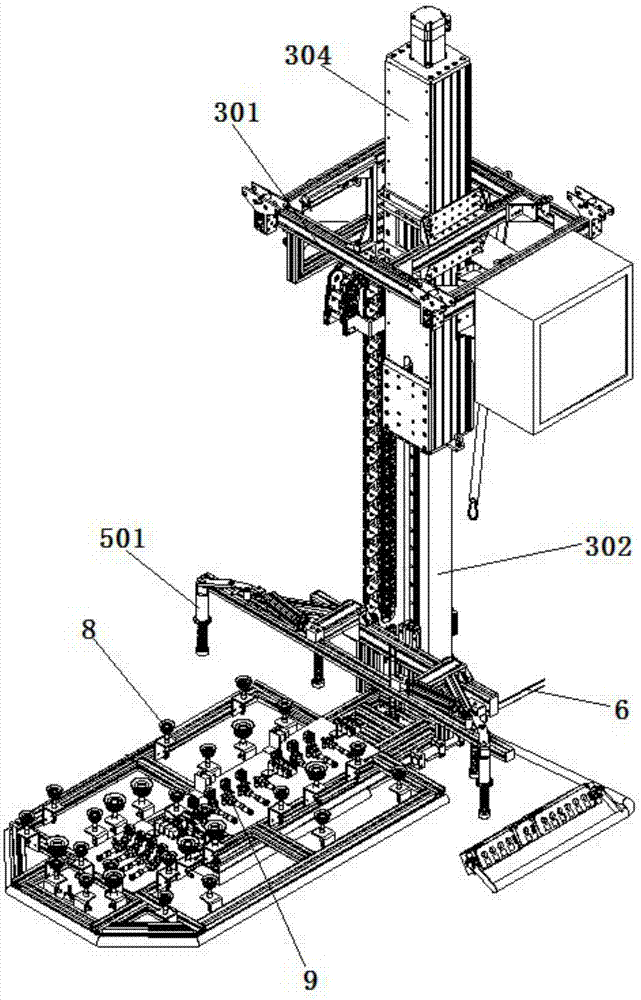

[0031] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , a semi-automatic car roof DVD assembly device provided by the embodiment of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the device includes a trolley 1 equipped with an electric power assist component, the trolley 1 is installed on a horizontal guide rail 2 arranged horizontally, and the trolley 1 can slide freely along the horizontal guide rail 2;

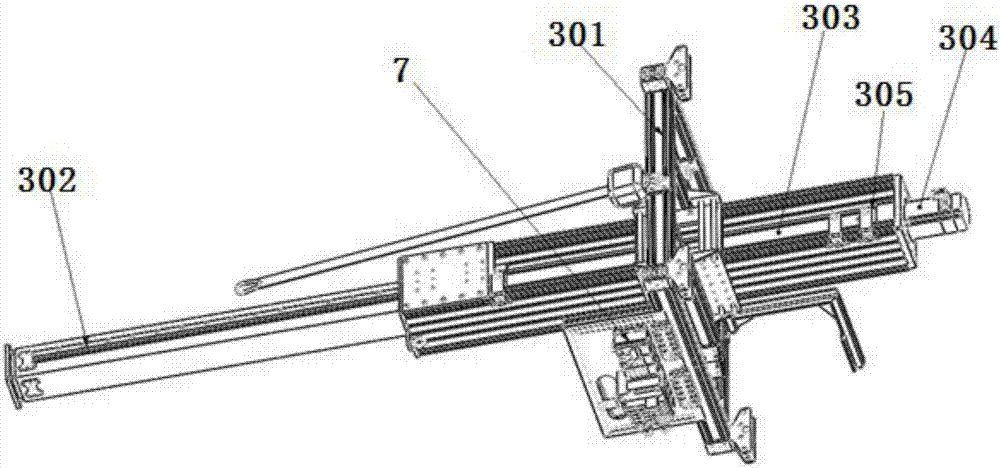

[0032] The gravity manipulator assembly 3, the gravity manipulator assembly 3 includes a profile bracket 301 for connecting with the vehicle, a linear guide rail 302 is set on the profile bracket 301, and a transmission ball screw is arranged on the linear guide rail 302 303, the transmission ball screw 303 is connected to the servo motor 304 provided on the profile bracket 301, the servo motor 304 is used to drive the transmission ball screw 303 to rotate so as to drive the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com