Vertical smoke tube type biomass boiler

A biomass boiler and smoke pipe technology, applied in the field of boilers, can solve problems such as damage and inability to filter harmful impurities thoroughly, and achieve the effects of prolonging flow time, improving heat exchange efficiency, and increasing collision probability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

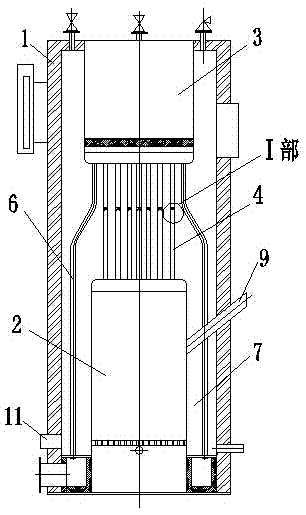

[0021] The present invention has a vertical structure as a whole, including a furnace body 1, a combustion chamber 2 is arranged at the lower part of the furnace body 1, and a combustion chamber 3 communicated with the combustion chamber 2 is arranged at the upper part of the furnace body 1;

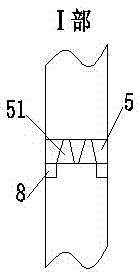

[0022] The combustion chamber 2 is connected to the combustion chamber 3 through the threaded smoke pipe 4, the threaded smoke pipe 4 is provided with a baffle 5 along the axial direction, and the baffle 5 is provided with several small holes 51, and the small holes 51 In the shape of a round table;

[0023] The lower part of the furnace body 1 is provided with an air outlet 11, and the recombustion chamber 3 is connected to the air outlet 11 through the return smoke pipe 6;

[0024] The furnace body 1 is provided with a liquid inlet and a liquid outlet, and the furnace body 1 is provided with a liquid chamber 7 communicating with the liquid inlet and the liquid outlet, and the liquid ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com