Deep dehumidification air handling unit

A wet air and unit technology, which is applied in the direction of using air flow as shielding, air conditioning system, space heating and ventilation, etc., can solve the problems that the air conditioning unit cannot accurately adjust the indoor humidity, and the single control effect is not ideal, so as to enhance the dehumidification effect. , Improve work performance and safety performance, the effect of large humidity adjustment margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

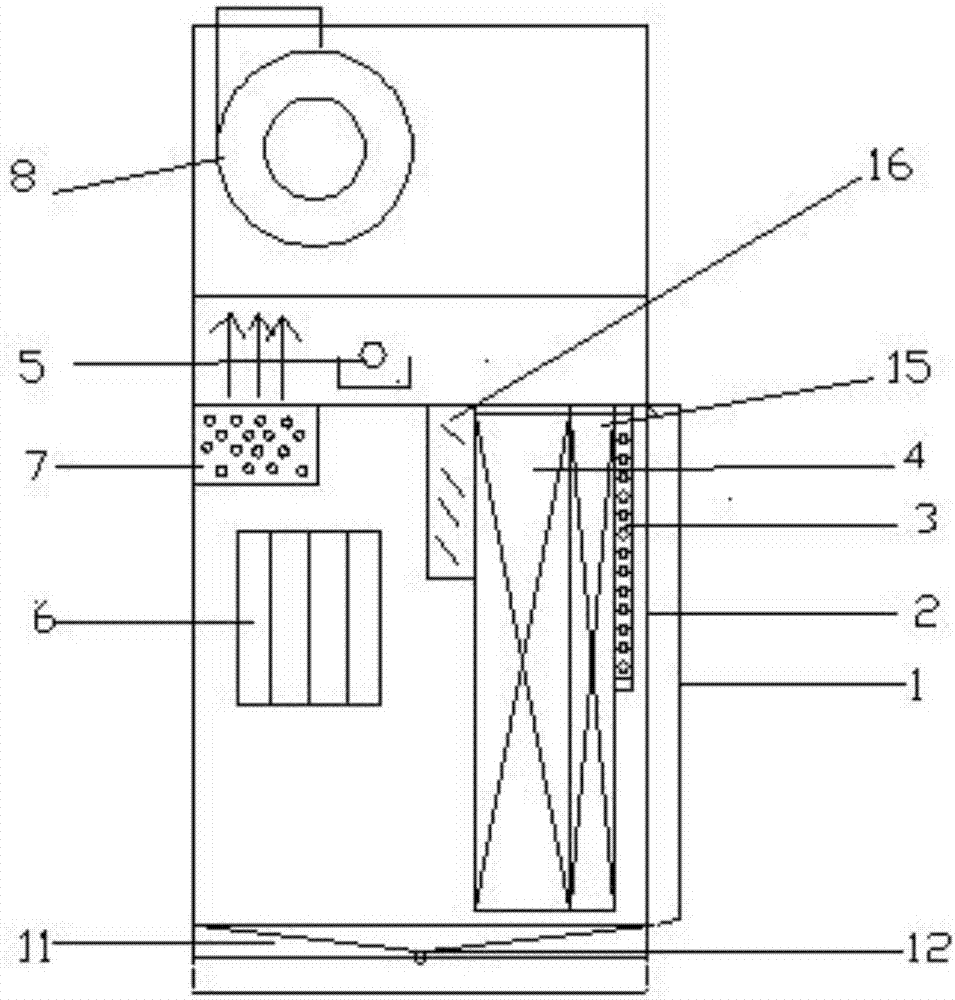

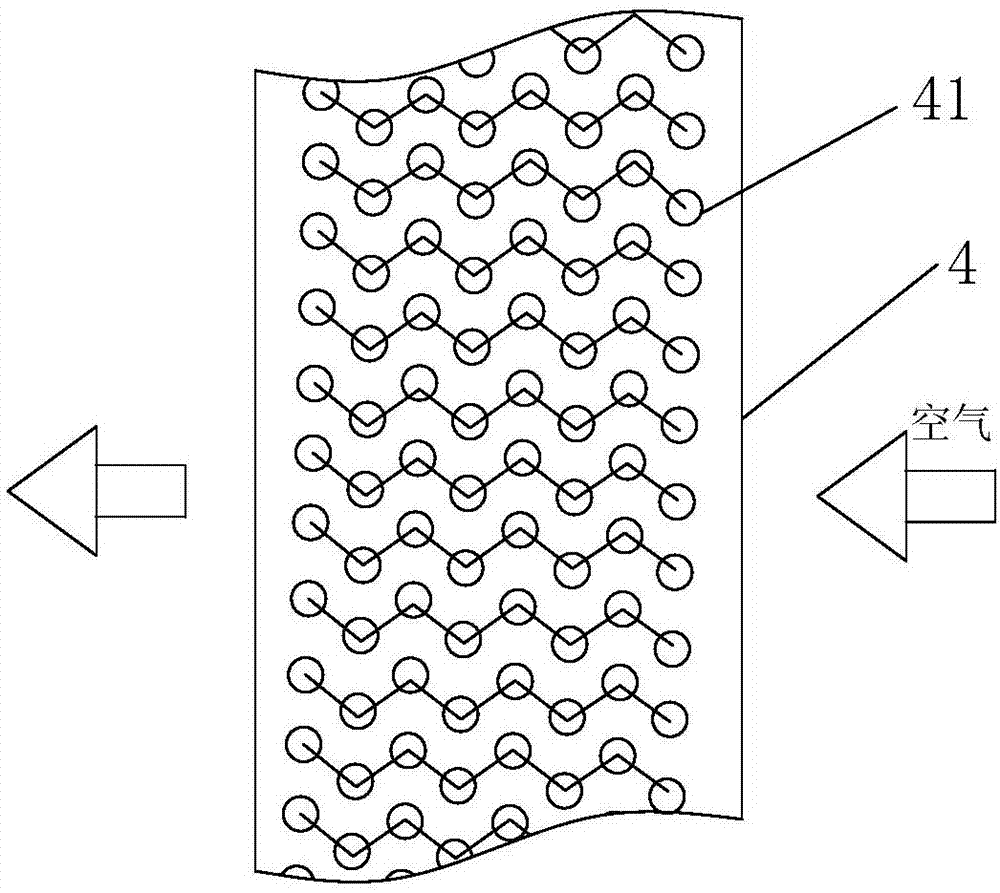

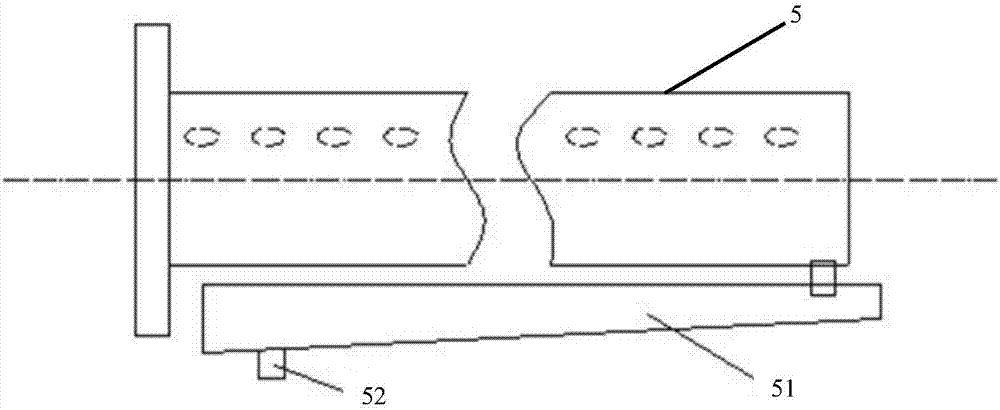

[0033] The present invention includes a unit box 2, which is provided with a return air outlet 1 with a primary filter, and the unit box 2 is provided with an evaporator 4, a rear electric heater 7, and a dry steam humidifier. Nozzle 5 and fan 8; the air entering the unit box 2 from the air return port 1 flows through the evaporator 4 to be cooled and dehumidified, and then enters the rear electric heater 7 to be heated to the required temperature, and then Humidify to the required humidity by the dry steam humidifying nozzle, and finally send it to the test room of the enthalpy difference laboratory through the fan 8; Adjustable outlet damper 16. The outlet air valve 16 includes a shutter, which covers the area of the air outlet of the evaporator 4. When the air needs to be deeply dehumidified, the area of the return air outlet can be blocked by ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com