Thermal error compensation system and method for embedded full-life-cycle machine tool

A full life cycle, compensation system technology, applied in the field of embedded full life cycle machine tool thermal error compensation system, can solve the problems of impact effect, unverified machine tool thermal error consistency, unfavorable user convenience, etc., to achieve thermal error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

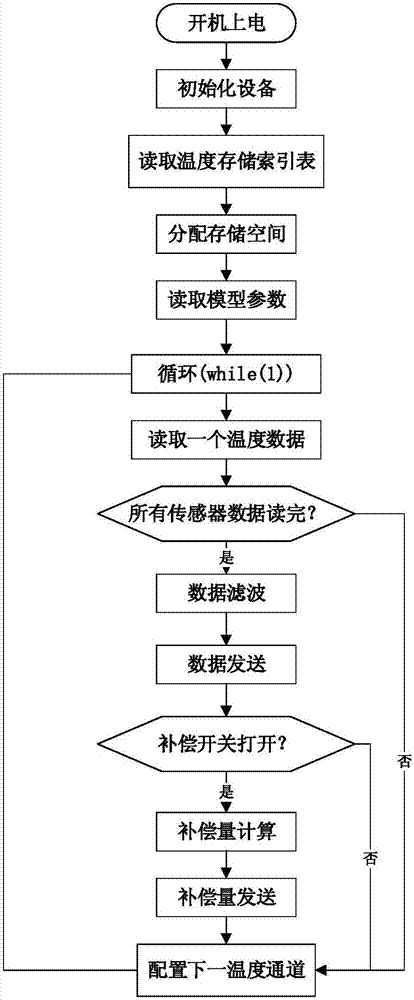

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

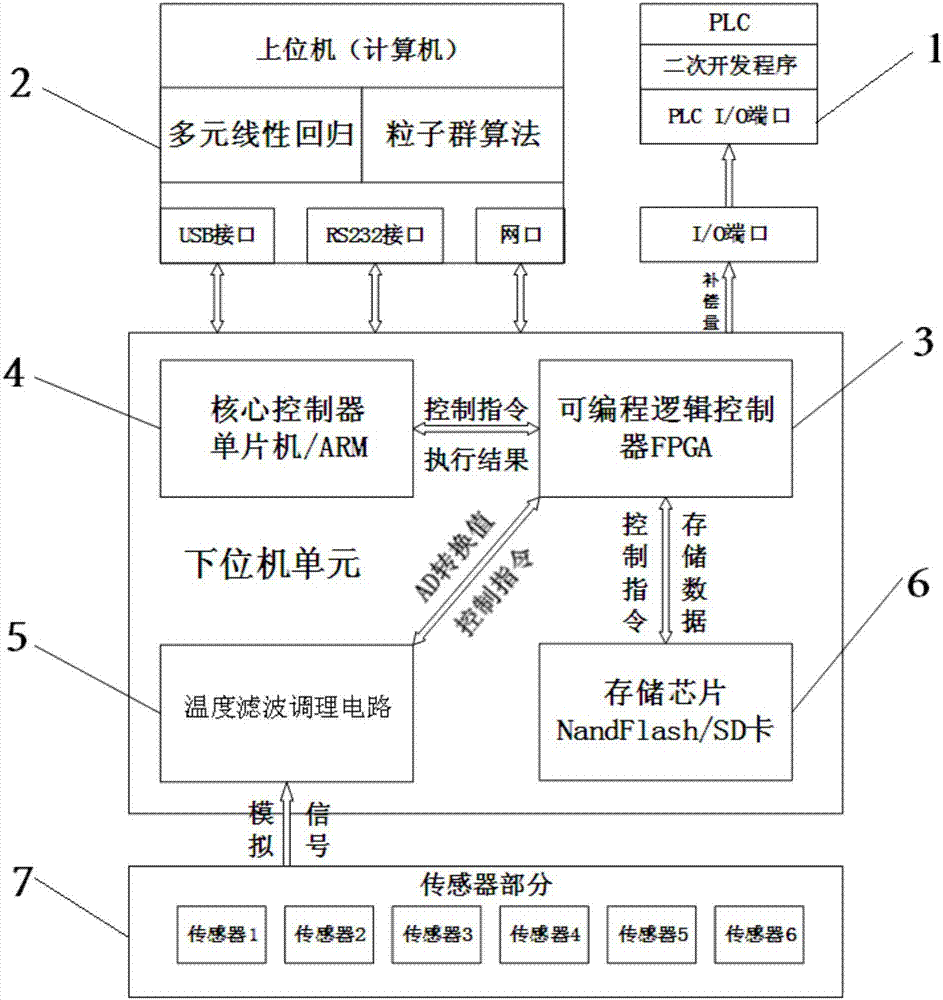

[0023] refer to figure 1 , the embedded full life cycle machine tool thermal error compensation system of the present invention includes a host computer 2, a PLC controller 1, a core controller 4, a programmable logic controller 3, a temperature filter conditioning circuit 5, a memory chip 6 and a A temperature sensor 7 for collecting the temperature of the machine tool, wherein the output end of the temperature sensor 7 is connected to the programmable logic controller 3 through the temperature filter conditioning circuit 5, and the programmable logic controller 3 is connected to the memory chip 6, the PLC controller 1 and the core control The device 4 is connected, and the upper computer 2 is connected with the core controller 4.

[0024] The programmable logic controller 3 is connected to the PLC controller 1 through the I / O port; the core controller 4 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com