A Method for Realizing On-line Monitoring and Diagnosis of Nuclear-level Digital Instrument and Control System

An I&C system and nuclear-level technology, applied in the field of on-line monitoring and diagnosis of nuclear-level digital I&C systems in pressurized water reactor nuclear power plants, can solve the problems of unable to find scan time overflow in time, obtain control processor program running status, and locate alarms Process inefficiency and other problems, to achieve the effect of convenient historical trend query and monitoring, ensuring safety and independence, liberating manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

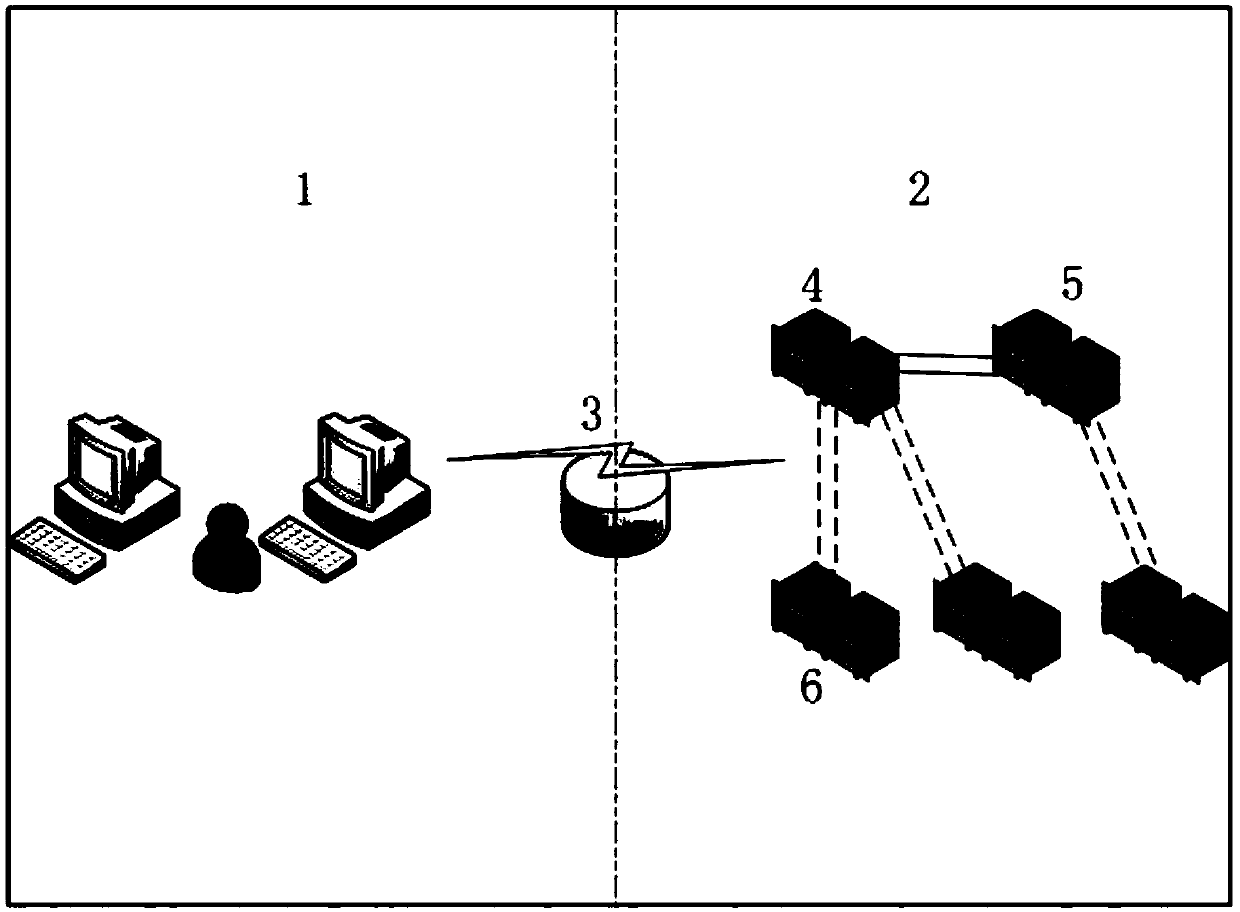

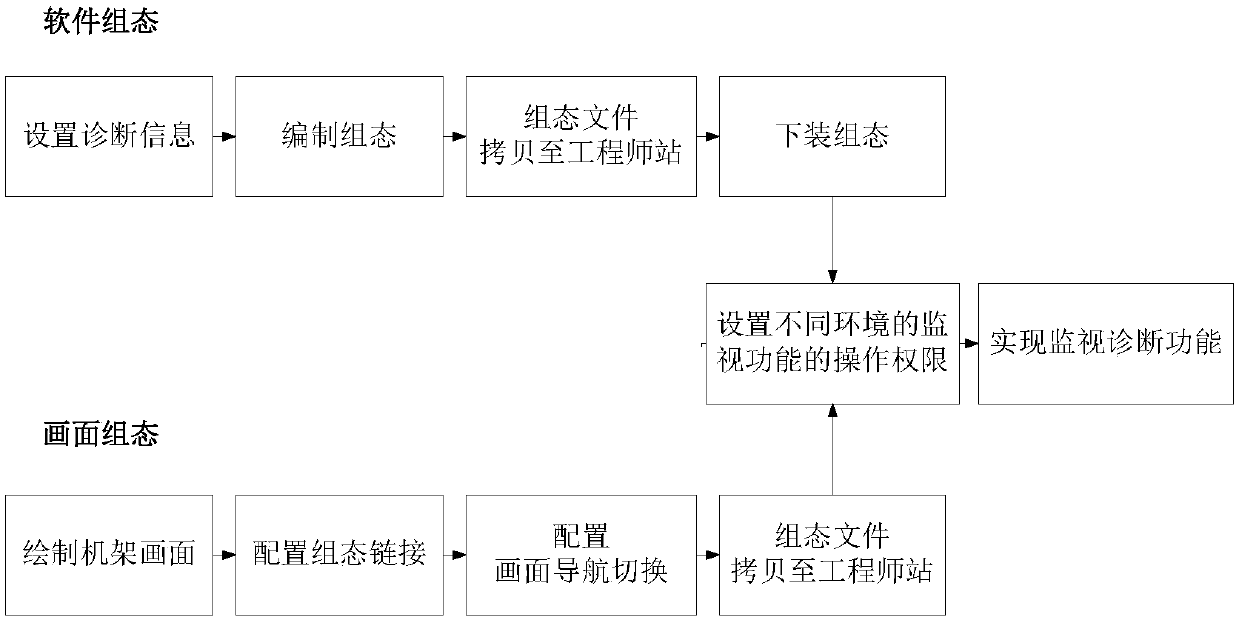

[0041]The present invention is a method for realizing on-line monitoring and diagnosis of a nuclear-level digital instrument control system. With the help of the internal diagnostic information set by the nuclear-level digital instrument-control system and the gateway and open communication protocol with the non-nuclear-level digital instrument-control system, through two The secondary development configures software configuration and screen configuration, obtains the internal diagnostic inform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com